White Vienna Granite Kitchen

White Vienna Granite Kitchen

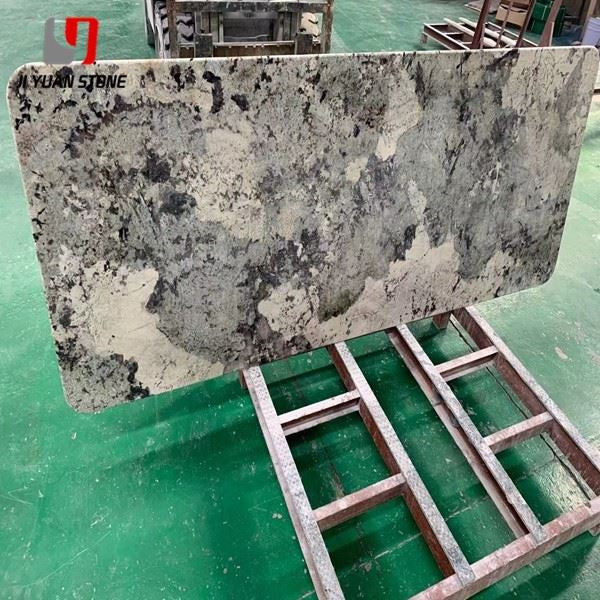

White Vienna Granite Kitchen Countertops – Timeless Beauty with Expert Craftsmanship

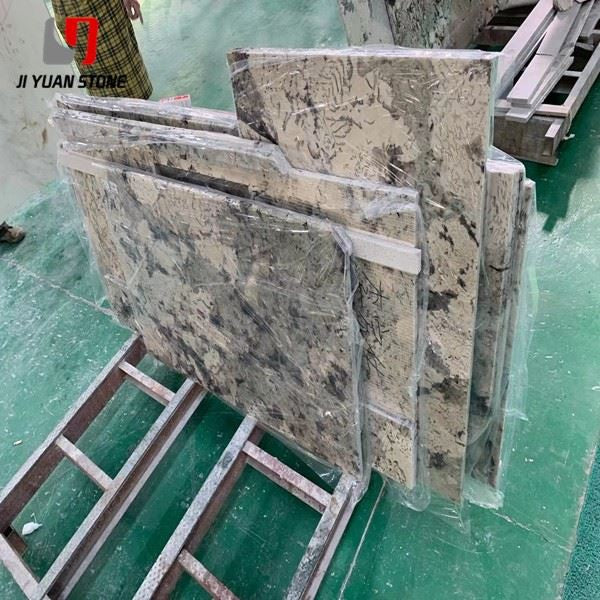

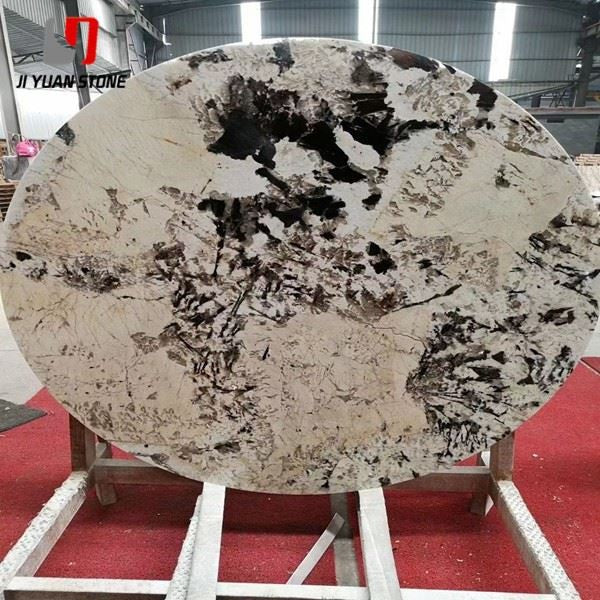

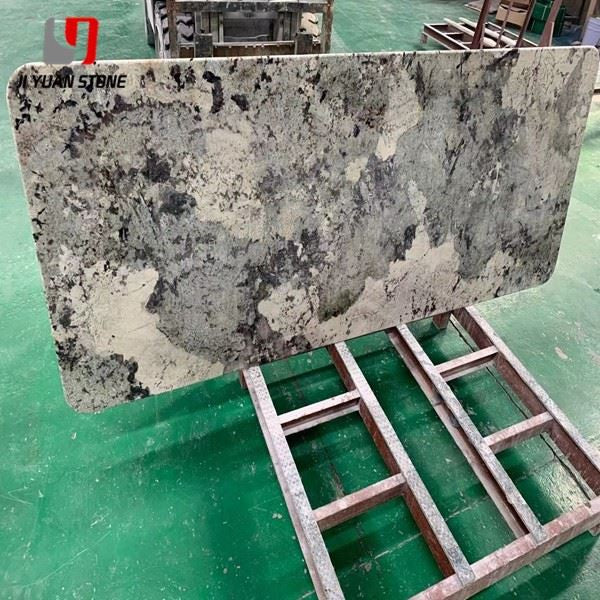

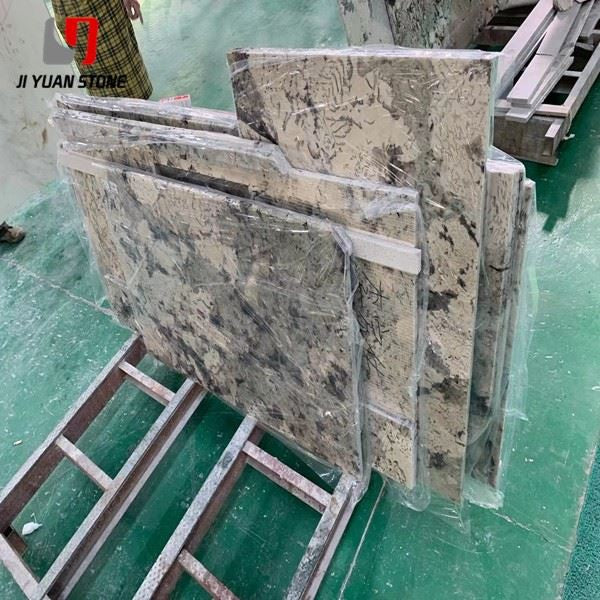

Introducing the White Vienna Granite Kitchen - a sleek and elegant addition to any home. Made with high-quality white Vienna granite, this kitchen brings a touch of luxury and sophistication to your space. With its durable and heat-resistant surface, cooking and entertaining has never been easier. Upgrade your kitchen today!

| Feature | Details |

|---|---|

| Product Name | White Vienna Granite Kitchen |

| Material | Granite Stone |

| Surface Finished | Honed, Polished |

| Finished Products | Floor Tiles, Wall Cladding, Countertops, Windowsills, Special-Shaped Tiles, Small Slabs, Swimming Pool, Steps, Wall Panel, Flooring, Veneers, Slabs, Coping Tiles, etc. |

| Thickness | 20mm, 30mm, 2cm, 2.5cm, (2+2)cm, 3cm, etc. |

| Application |

Hotel, Villa, Apartment, Office Building, Hospital, School, Mall, Sports Venues, Leisure Facilities, Supermarket, Warehouse, Workshop, Park, Farmhouse, Courtyard |

| Vanity Top Size |

25×19×3/4", 31×19×3/4", 37×19×3/4", 43×19×3/4", 49×19×3/4", 61×19×3/4", 25×22×3/4", 31×22×3/4", 37×22×3/4", 43×22×3/4", 49×22×3/4", 61×22×3/4", or custom sizes |

| Kitchen Top Size |

Countertop: 96"x26"x3/4", 108"x 26" x3/4", etc. Peninsula: 36"x78", 28"x96", 28"x108", etc. Island: 36"x84", 36"x96", 36"x108", etc. Snack Bar: 12"x96", 16"x96", 108"x18" , etc. |

Discover the refined elegance of White Vienna Granite, a premium choice for kitchen countertops that balances aesthetic appeal with superior durability. Its soft white tones interspersed with graceful grey veining offer a clean, luxurious look, perfect for both classic and contemporary kitchen interiors.

How Much Do You Know?

Stone is highly valued not only for its natural texture, which creates unique artistic visual effects but also for its surface treatments, which add depth and richness. Below is a categorized list of different types of stone and processing techniques that help bring out the best in granite like White Vienna.

🔹 1. Basic Stone Classifications

- Raw Material: Irregularly shaped stone directly extracted from a mine.

- Blocks: Large stone blocks with six regular surfaces, used for decorative stone processing.

- Material Stone: Processed stone with specific dimensions for construction purposes.

🔹 2. Stone Processing Types

- Wool Board: A thick, untreated stone slab cut with a disc saw, sand saw, or frame saw.

- Rough Board: A slab with a smooth yet rough surface, showing regular processing marks.

- Chopping Axe Board: A rough slab processed using an axe.

- Hammered Sheet: A rough slab processed using a flower hammer.

🔹 3. Fire & Water-Based Treatments

- Fire-Finished Panel: A rough-finished panel made by exposing it to flames from acetylene, oxygen, propane, or liquefied petroleum gas.

- Fire & Water Flushed Panel: A stone panel that is first flame-treated and then impacted with water.

- Water-Washed Board: A panel impacted with water, creating small holes and pits while preserving the stone’s natural color.

🔹 4. Machine Processed Stone

- Machine-Planed Board: A rough board processed by machine planing.

- Thin Plate: A flat, smooth-surfaced stone panel.

- Mirror Plate: A highly polished stone with a mirror-like gloss.

- Matte Sheet: A stone slab with a smooth surface but low luminosity.

- Antique Stone: A matte-finished panel treated with grinding brushes to create an antique look. Some are first flame-treated and then polished with brushes.

🔹 5. Thickness-Based Classification

- Thin Plate: A stone panel with a thickness of less than 15mm.

- Thick Plate: A stone panel with a thickness greater than 20mm.

🔹 6. Shape-Based Classification

- Ordinary Plate: A square or rectangular panel.

- Special-Shaped Sheet: A non-square, non-rectangular panel.

🔹 7. Textured & Decorative Finishes

- Natural Panel: A panel with a chiseled or hammer-processed mountain-like texture.

- Litchi Top Sheet: A panel hammered to create a rough surface resembling lychee skin.

- Longan Panel: A panel struck with a flat-shaped hammer in a staggered pattern to create a texture similar to longan skin.

- Blind Stone: A stone panel with uneven stripes, installed on blind roads for tactile guidance.

- Machine-Cut Sheet: A panel with visible strip marks from machine cutting.

- Mushroom Panel: A stone slab hammered with a chisel and hammer to create an uneven, mountain-like texture.

Whether you're redesigning your kitchen or building from scratch, White Vienna Granite offers the ideal blend of style, resilience, and artisanal stonework. Elevate your space with a material that's as beautiful as it is built to last.

Share