White Travertine Wall Tiles

White Travertine Wall Tiles

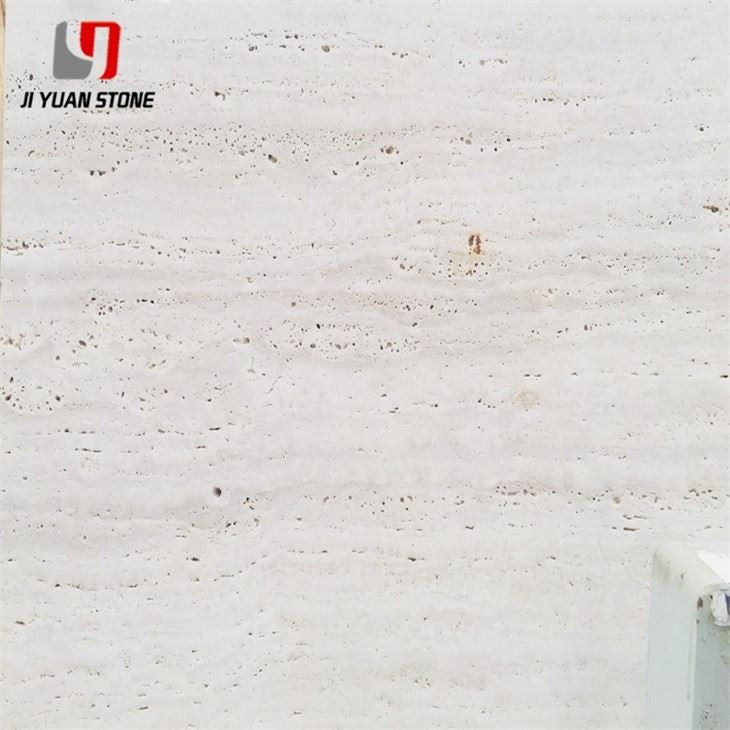

White Travertine Wall Tiles – A Natural Stone Statement for Timeless Walls

Upgrade your home's interior with our elegant White Travertine Wall Tiles. Made from high-quality travertine, these tiles add a touch of sophistication to any room. With their light color and natural stone texture, they create a peaceful and timeless ambiance. Perfect for bathrooms, kitchens, and more.

| Feature | Details |

|---|---|

| Big slab Size |

|

| Tile Size |

|

| Vanity top |

|

| Countertop |

|

| Stair | step100-150x30-35x2/3cm riser100-150x12-17x2/3cm |

| Quality Control |

1) Polished degree: 90 degree or up. 2) Thickness tolerance: +/-0.5mm 3) Diagonal tolerance : +/-1mm. 4) Surface flatness tolerance: +/-0.3mm. 5) Adjacent edge verticality tolerance: +/-0.5mm, Precise Cutting by infrared-ray-cut machine. |

Give your interior or exterior walls a sophisticated, high-end look with our White Travertine Wall Tiles. Known for their elegant texture, soft ivory tone, and natural veining, these tiles are a popular choice for both residential and commercial spaces. Perfect for accent walls, facades, fireplaces, and pillars, white travertine adds warmth and luxury to any architectural design.

Made from premium travertine stone, each tile is carefully selected, precision cut, and polished for smooth installation and lasting beauty.

🛠️ Prepare the White Travertine Wall Tiles – Key Steps

1. Material Selection

- Select travertine plates with consistent color and veining.

- Technicians should verify tile specifications, including size, tone, and pattern.

- Uniformity ensures a flawless and cohesive finish across your entire wall surface.

2. Processing & Transportation

- Tiles are cut, polished, and edge-treated using advanced computer-controlled equipment.

- Special-shaped tiles—like arc slabs and corner pieces—are custom chamfered and polished for accuracy.

- Each tile is carefully packed for transportation to prevent damage such as cracks or chipped edges.

🧱 Wall Skeleton Framework Installation

1. Surface Preparation

- Verify all structural dimensions against project drawings.

- Any cylindrical surfaces outside tolerance limits must be corrected.

- The thickness from the base to the veneer surface should be at least 5 cm.

- Ensure the base layer is rigid, smooth, clean, and free of dust or oil.

- Apply horizontal and vertical grid lines to mark the column's centerline.

2. Skeleton Installation

- Install the skeleton framework according to the measured reference lines.

- Use connectors to securely fix the framework to the main structure.

🔩 Two Common Fixing Methods

1 . Embedded Iron Parts Method:

- Iron parts are embedded during structural construction.

- Connectors are welded to these fixed iron parts.

- This method ensures strong anchoring but depends on precise civil construction.

2 . Expansion Bolt Method (More Common):

- Drill holes in the main structure and insert expansion bolts.

- Attach connectors to the structure using bolts.

- This approach is more flexible on-site and easier to control.

✨ Product Features:

- ✅ Natural White Finish – Elegant and timeless surface design.

- ✅ Precision Cut & Polished – Suitable for special shapes and curves.

- ✅ Strong Wall Framework Support – Installed with a rigid skeleton system.

- ✅ Indoor & Outdoor Use – Weather-resistant and fade-resistant.

- ✅ Perfect for Columns, Facades, and Accent Walls – Brings out architectural beauty.

🛒 Order White Travertine Wall Tiles today to elevate your wall design with luxury and performance. Our expert team ensures material consistency, technical accuracy, and safe delivery. For installation guidance or bulk inquiries, reach out to us anytime.

Share