White Travertine Outdoor Tiles

White Travertine Outdoor Tiles

White Travertine Outdoor Tiles – Timeless Elegance for Outdoor Living

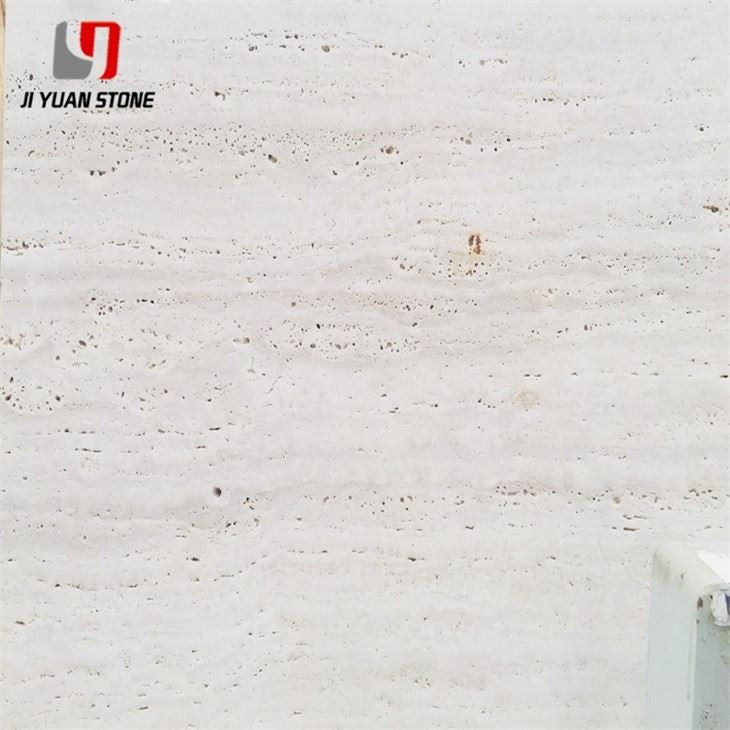

Enhance the aesthetic of your outdoor space with our White Travertine Outdoor Tiles. Made from durable and natural white travertine, these tiles add a touch of elegance to any patio, pool, or walkway. With their slip-resistant surface and low-maintenance qualities, they are perfect for outdoor areas. Create a beautiful and functional outdoor space with these high-quality tiles.

| Feature | Details |

|---|---|

| Big slab Size |

|

| Tile Size |

|

| Vanity top |

|

| Countertop |

|

| Stair | step100-150x30-35x2/3cm riser100-150x12-17x2/3cm |

| Quality Control |

1) Polished degree: 90 degree or up. 2) Thickness tolerance: +/-0.5mm 3) Diagonal tolerance : +/-1mm. 4) Surface flatness tolerance: +/-0.3mm. 5) Adjacent edge verticality tolerance: +/-0.5mm, Precise Cutting by infrared-ray-cut machine. |

Enhance your outdoor spaces with the natural beauty and durability of White Travertine Outdoor Tiles. Perfectly suited for patios, facades, walkways, and pool surrounds, these tiles combine refined aesthetics with long-lasting strength. Their anti-slip surface and resistance to weathering make them an ideal choice for residential and commercial outdoor settings.

Crafted from premium natural travertine, these tiles feature subtle textures and a clean, bright tone that complements modern and traditional landscaping designs alike. Whether you're revamping a patio or cladding an exterior wall, white travertine delivers lasting style and structural integrity.

🏗️ Installation Guide for White Travertine Outdoor Tiles

For professional results, follow these step-by-step installation practices designed for maximum stability and durability.

🔩 Fixing with Expansion Bolts

- Ensure proper embedding depth of expansion bolts for maximum pulling force.

- Use percussion drills to drill holes to the required depth in concrete structures.

- Avoid steel bars by adjusting bolt positions when drilling; always secure to strong structural points.

- Once the connecting pieces are firmly fixed, begin installing the skeleton framework.

🛠️ Skeleton & Framework Installation

- Install vertical rods first, as they are anchored to the main structure.

- Once vertical members are in place, install horizontal rods.

- Use section steel materials that can be bolted, welded, or mechanically fastened.

- Apply anti-rust paint to steel frames, ensuring the number of paint passes meets project specs.

🧱 Wiring & Fixing White Travertine Tiles

- Maintain consistent spacing in the horizontal keels based on tile height.

- Use steel wire or stainless steel wire to secure tiles in place after setting the frame.

🧵 Steel Wire Mesh Setup

- Use 16–18 gauge steel wire mesh with 20–25 mm grids or galvanized iron wire.

- Steel mesh should not be welded directly to the angle iron skeleton.

- Instead, weld steel mesh to the surface of the angle iron, and further reinforce using 8-gauge iron wire.

- Weld the entire mesh securely to the main skeleton for stability and weight distribution.

🔧 Final Tile Binding & Support

- Tie horizontal lashing wires across each layer of horizontal keels.

- Wires must extend through the mesh to support the travertine tiles.

- Tile sizes under 100mm × 250mm can also be bound using steel wires alone.

- Ensure each surface has at least one lashing wire for proper support.

🌟 Product Highlights

- Natural Stone Beauty: Elegant white tone adds timeless charm to outdoor spaces.

- Slip-Resistant Surface: Safe for walkways, pool decks, and high-traffic areas.

- Weatherproof Durability: Resistant to heat, moisture, and wear.

- Versatile Application: Suitable for walls, columns, pavements, and facades.

- Expert Installation Guide Included: Ensures proper structural and aesthetic results.

🛒 Order White Travertine Outdoor Tiles today for a seamless blend of sophistication, function, and enduring performance. Need help with technical specs or bulk orders? Contact our stone experts now for personalized support.

Share