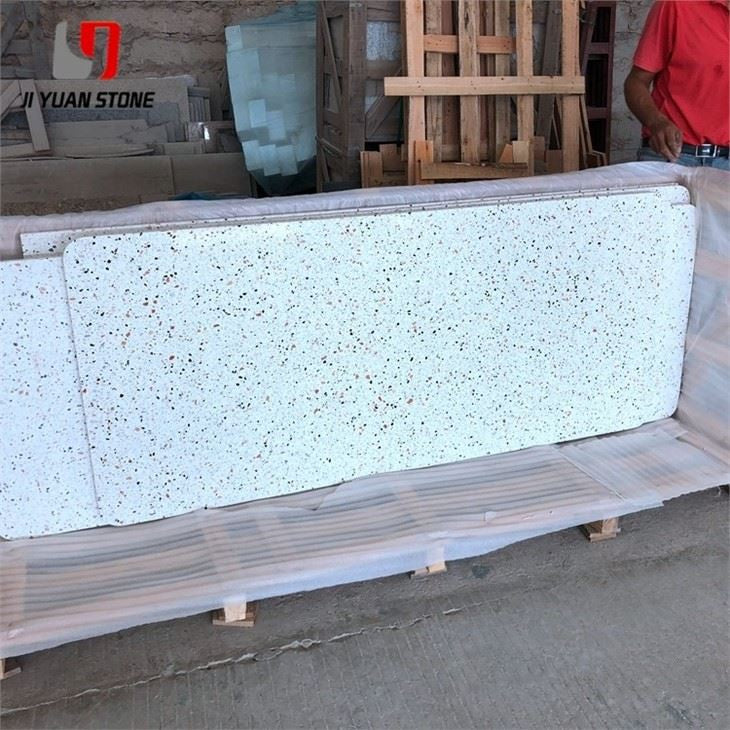

White Terrazzo Dining Table

White Terrazzo Dining Table

What is a White Terrazzo Dining Table?

Crafted from durable white terrazzo, this dining table offers a unique blend of modern style and long-lasting use. With its sleek design and sturdy construction, it's the perfect centerpiece for any dining room. Elevate your dining experience with this elegant and timeless piece.

| Feature | Details |

|---|---|

| Material | Terrazzo |

| Surface Finish | Polished,Honed |

| Countertops |

|

| Vanity Tops Size |

|

| Edge Style | Bull nose, ogee, bevel, eased, polish, etc |

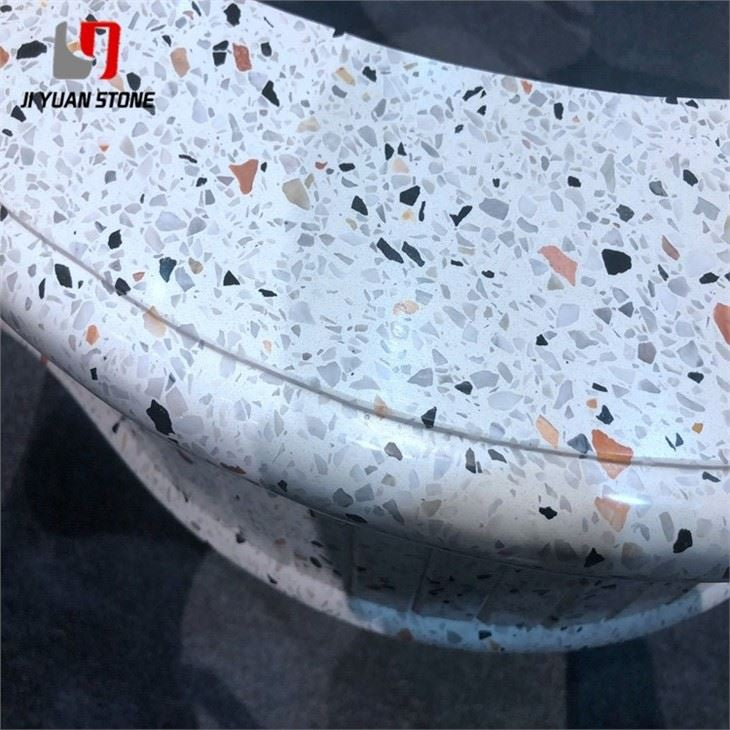

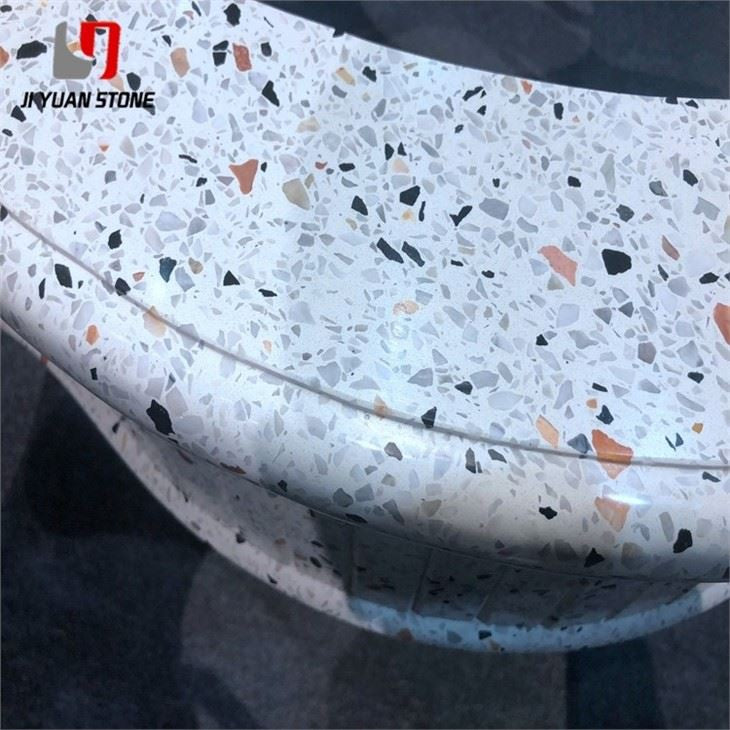

A White Terrazzo Dining Table is celebrated for its unique design, featuring irregular pebble patterns and dot-like textures that create a sense of “sameness with subtle differences.” This unpredictability gives terrazzo its dynamic beauty, making it a fashion favorite in modern interior design.

Traditionally, terrazzo is crafted by mixing crushed stone, glass, quartz, and other aggregates with cement binders. Once set, the surface is ground and polished to reveal a stunning speckled pattern. For dining tables, terrazzo can be constructed using two main methods: on-site pouring or factory prefabricated plates. Each method offers distinct benefits and characteristics.

1. On-Site Pouring Terrazzo Dining Table

On-site pouring is the traditional method, where terrazzo is poured directly at the installation site by skilled workers.

Advantages:

- ✅ Seamless Splicing – Creates a continuous surface with no visible joints.

- ✅ Large-Area Formation – Enables larger slabs without color variation.

- ✅ Elegant Aesthetic – Produces beautiful mosaic-like patterns.

Disadvantages:

- ⚠️ Manual Operation – Finish quality depends heavily on craftsmanship.

- ⚠️ Physical Properties – May lack density compared to machine-pressed terrazzo.

- ⚠️ Surface Flatness – Polishing can result in slight waviness.

- ⚠️ Strict Conditions – Labor-intensive, requiring dedicated curing time.

- ⚠️ Not Suitable for Walls – Limited to flat horizontal installations.

Potential Problems:

- Bonding strength may weaken over time, causing aggregate loosening.

- High water absorption makes the surface prone to stains.

- Less dense and strong, with higher risk of cracks.

- Difficult to repair once damaged.

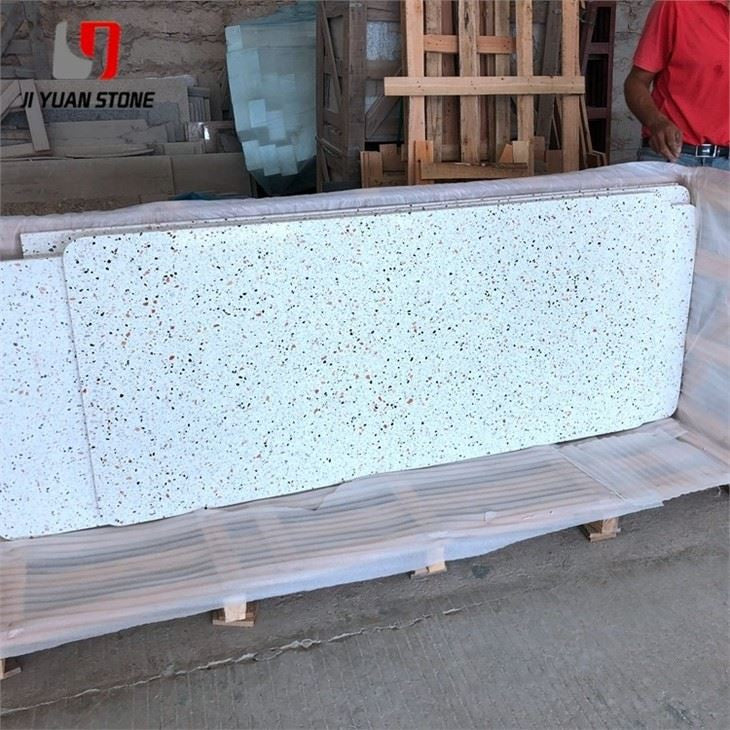

2. Factory Prefabricated Terrazzo Dining Table

Factory-prefabricated terrazzo tables are produced under controlled conditions with advanced equipment, ensuring consistent quality and strength.

Key Features:

- ✅ Made with vibration, high pressure, and precise cutting, achieving high density and durability.

- ✅ Similar to tiles or marble in performance.

- ✅ Versatile and adaptable for different applications.

- ✅ Consistent surface flatness and polished finish.

This method ensures better strength, reduced water absorption, and long-lasting quality compared to on-site poured terrazzo.

Choosing the Right White Terrazzo Dining Table

- If you prefer a customizable and seamless look, an on-site poured terrazzo table offers artisanal charm.

- If you want consistent quality, durability, and low maintenance, a factory-prefabricated terrazzo table is the best choice.

Why Choose a White Terrazzo Dining Table?

- ✅ Modern Elegance – Distinctive dot and pebble textures for a contemporary aesthetic.

- ✅ Durability – Strong surface that withstands daily use.

- ✅ Versatility – Complements both minimalist and luxurious interiors.

- ✅ Timeless Design – A fashion-forward yet classic piece of furniture.

Conclusion

The White Terrazzo Dining Table is more than just a piece of furniture—it’s a blend of art, tradition, and modern craftsmanship. Whether you choose on-site poured terrazzo for seamless artistry or factory-prefabricated terrazzo for consistent quality, both options bring elegance, strength, and unique beauty into your dining space.

Share