White Seashell Marble

White Seashell Marble

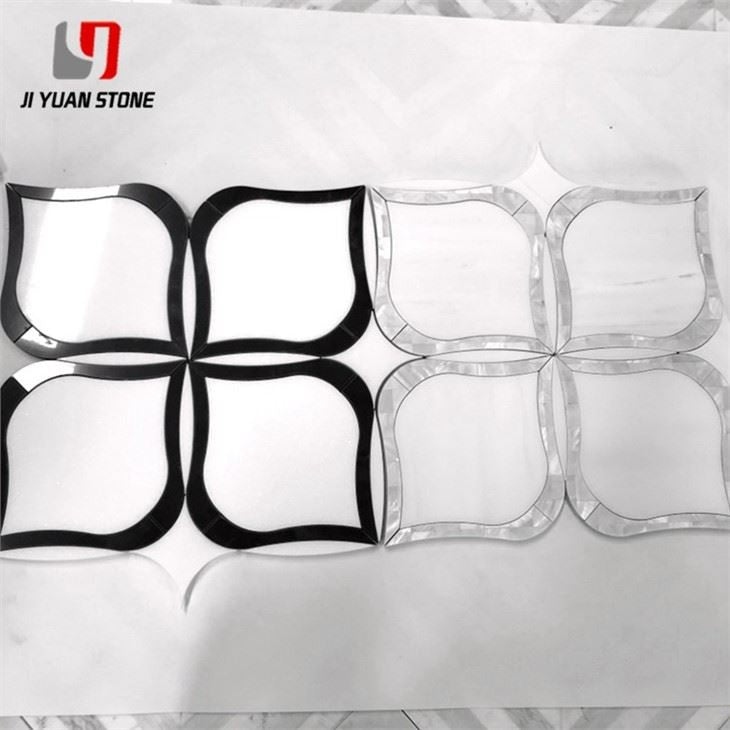

White Seashell Marble Tiles – Handcrafted Elegance for Luxurious Interiors

Discover the timeless elegance of our White Seashell Marble. With its stunning white color and natural seashell patterns, this marble adds a touch of sophistication to any space. Its durable and versatile nature makes it perfect for both indoor and outdoor applications. Elevate your design with White Seashell Marble.

| Feature | Details |

|---|---|

| Material | Mother of pearl, Seashell, Natural Marble Stone, Travertine, Limestone |

| Colour | As pictures show or customized |

| Shape | Square, Basketweave, Mini brick, Modern brick, Herringbone, Subway, Hexagon, Octagon, Mixed, Grand fan, Penny round, Hand clipped, Tesserae, Random strip, River rocks, 3D cambered, Pinwheel, Rhomboid, Bubble round, Circle bubble, Stacked, etc... |

| MOQ | Unrestricted Please contact us for the newest catalog of mother of pearl mosaics! |

Elevate your interior spaces with White Seashell Marble Tiles, a premium handmade surface solution crafted from natural wild shells. Perfect for artistic decor and upscale installations, these unique tiles combine elegance, craftsmanship, and functionality to create a seamless and luminous look in any room.

🌊 Natural Shell Material & Custom Backing Options

Each tile is handcrafted using exquisite shell varieties including:

- Chinese freshwater MOP (Mother of Pearl) shell

- Black MOP shell

- White MOP shell

- Abalone

- Pen shell

- Brown MOP

Available on mesh-backing or tile base with customizable options like PVC, magnesium board, acrylic board, aluminum-plastic board, and wooden board.

🏠 Ideal for Sophisticated Indoor Applications

Recommended for a wide range of interior decorative uses, including:

- Interior walls

- Kitchen backsplashes

- Countertops and tables

- TV background walls

- Mirror frames and shopwindow displays

- Pillar wrapping

- Light-use bathroom flooring

- Furniture inlay and decorative accents

⚠️ Note: Not suitable for high-heat areas (ovens, fireplaces) or outdoor use due to UV sensitivity.

🔧 White Seashell Marble Seamless Splicing – A Flawless Finish

White seashell marble is favored for its noble and reflective aesthetic, and its beauty is further enhanced through seamless splicing, a meticulous process involving:

1 . Color-matched caulking between slabs

2 . Grinding and polishing for a unified surface

3 . Waxing or crystal surface treatment for lasting brilliance

This process ensures a smooth, continuous surface that maximizes the stone’s visual impact.

📏 National Quality Standards for Seamless Stone Processing

Seamless processing meets the highest quality benchmarks:

- Perfect Seams: No half, broken, or black seams—appears flawless from 2 meters away

- Color Consistency: No chromatic variation between filler and shell surface

- Smooth Patterns: Waterjet cuts and parquet stitching must be precise and natural

- Fracture Repair: Repaired zones must match original shine and tone

⚙️ Material Selection for Seamless Perfection

Choose materials that ensure durability and long-term aesthetics:

- Strong Adhesion to prevent detachment

- High Polishability for mirror-smooth surfaces

- Low Shrinkage to maintain form

- Discoloration Resistance for long-term color integrity

🌟 Why Choose White Seashell Marble from PurchaseStones?

- Handmade using natural wild shells

- Superior craftsmanship and aesthetic

- Tailored for sophisticated interior use

- Backed by national quality standards and seamless technology

- Versatile backing options for any installation requirement

Transform your interiors with the timeless elegance of White Seashell Marble Tiles—a perfect blend of luxury, craftsmanship, and contemporary style. Whether you're designing a lavish bathroom, artistic wall, or high-end countertop, these tiles deliver sophistication in every square inch.

🛒 Shop now at PurchaseStones and bring your design vision to life with artisanal beauty.

Share