White Marble Limestone

White Marble Limestone

White Marble Limestone – A Natural Fusion of Art, Architecture, and Endurance

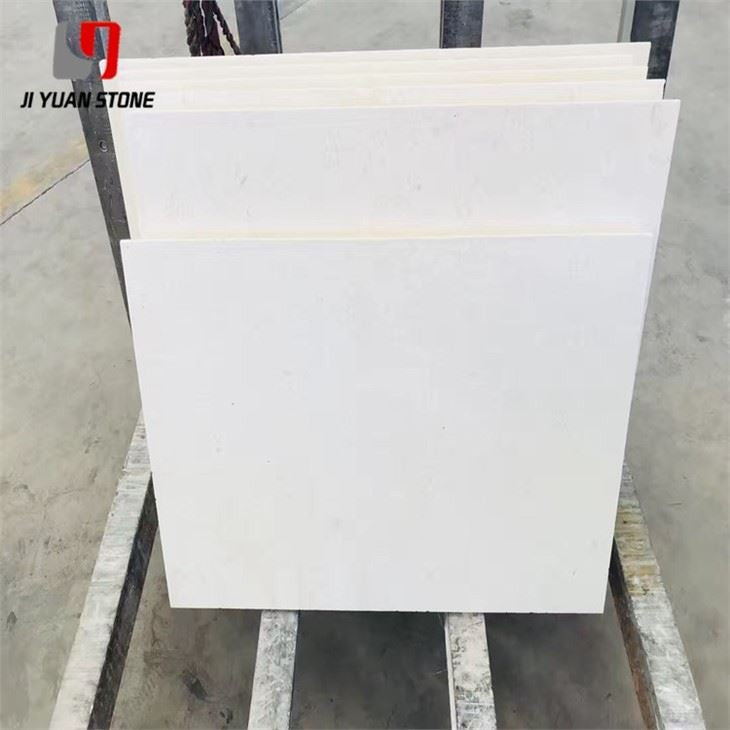

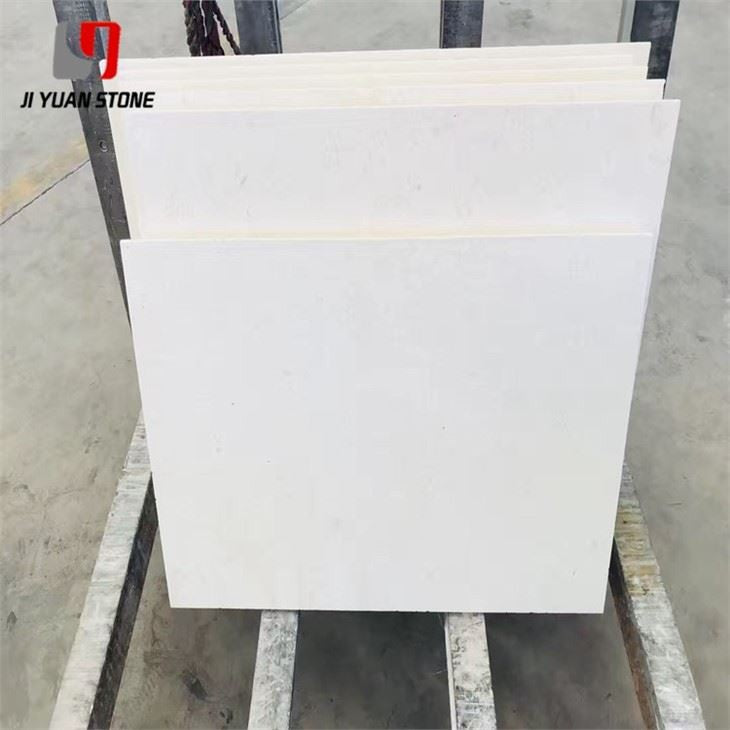

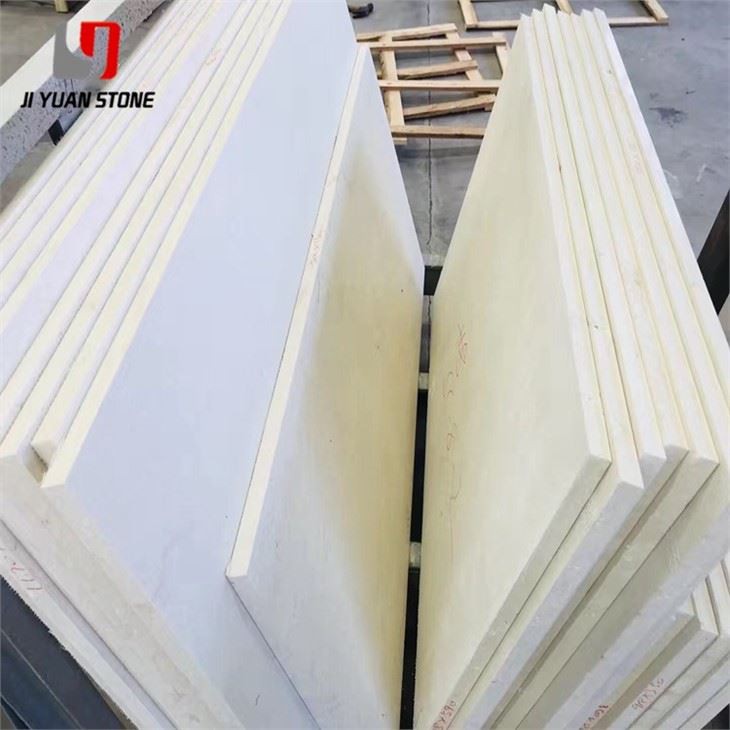

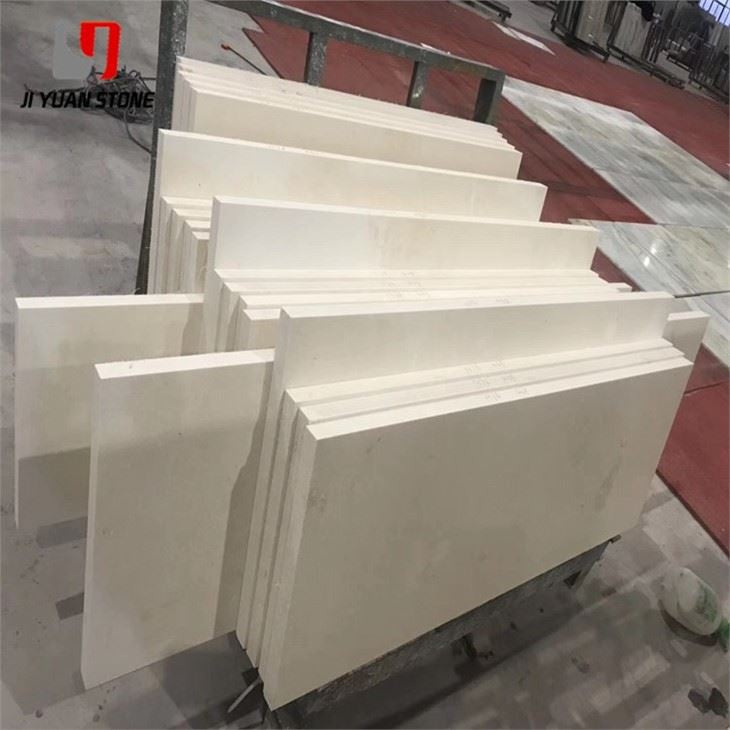

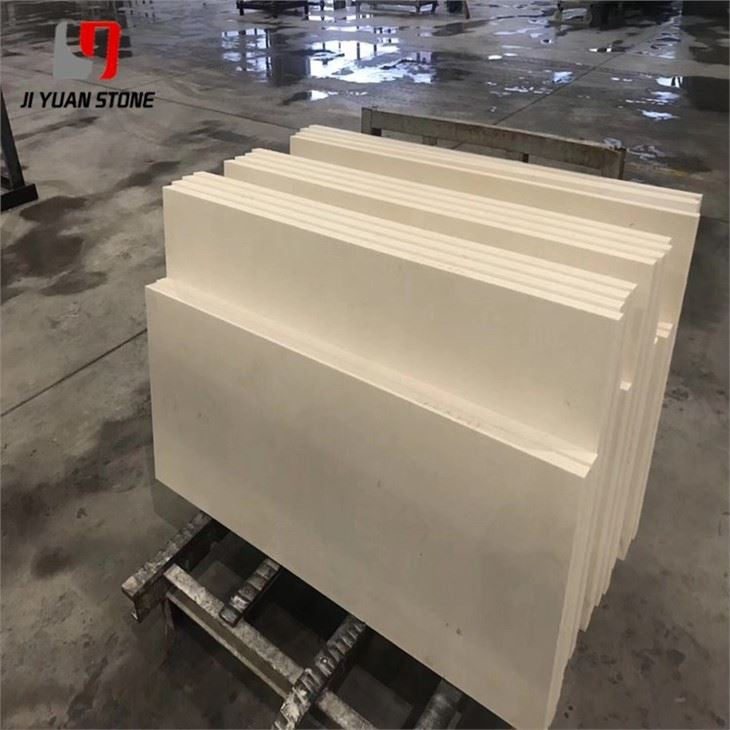

Our White Marble Limestone is a beautiful and durable natural stone that boasts a timeless elegance. With its pure white color and smooth surface, it adds a touch of sophistication to any space. Our limestone is also highly durable and resistant to wear and tear, making it a practical and long-lasting choice for various applications. Enhance your project with the luxurious and practical features of our White Marble Limestone.

Discover the timeless appeal of White Marble Limestone, a natural stone sculpted over millions of years into a refined light beige tone. Known for its subtle elegance, exceptional durability, and unique surface textures, this premium material is highly favored by architects, builders, and project owners looking to infuse buildings with sophistication and modernity.

Perfect for wall cladding, outdoor flooring, and large-scale architectural projects, white marble limestone is more than just a building material—it’s an expression of engineering artistry.

🏛️ For Architects – Nature's Masterpiece, Tailored for Design

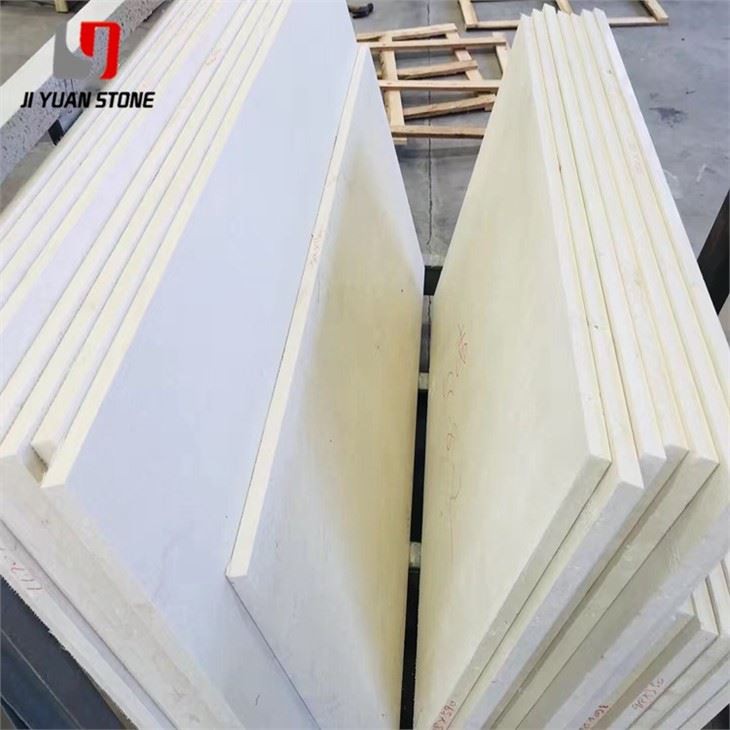

- Formed over millions of years, resulting in a soft light beige color with graceful veining

- Each stone piece carries a distinct natural texture, promoting a minimalist and modern style

- The stone's comfortable color and smooth touch offer a sensory experience that connects deeply with nature and life

- Highly durable—resistant to harsh weather, maintaining beauty and integrity for decades

- Breaks away from the dull uniformity of traditional granite by bringing organic warmth to structural aesthetics

- Enables a perfect fusion of engineering precision and artistic expression, making it a top choice for contemporary architecture

🧱 Applications:

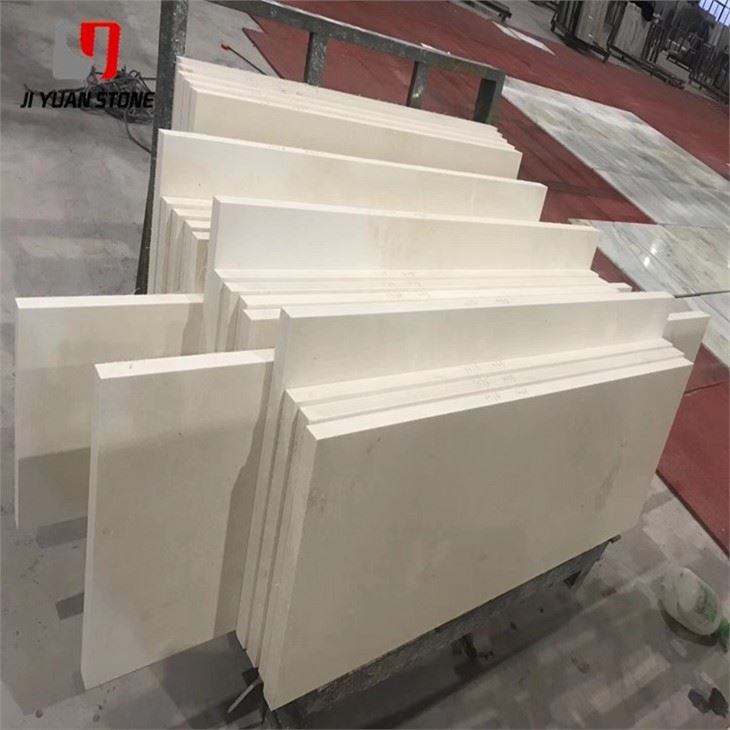

- Wall Cladding

- Facades

- Outdoor Pavement

- Commercial Interiors

- Cultural or Public Buildings

- Sculptural Installations

Its ability to elevate ordinary spaces into visually dynamic environments makes white marble limestone a go-to solution for both commercial and high-end residential projects.

🔧 Polishing Procedure of White Marble Limestone

The finishing and polishing process of white marble limestone is crucial in revealing its rich textures and smooth surface. The journey to perfection begins once the stone is shaped using a copying machine. It then moves to the assembly workshop where meticulous polishing begins:

🔹 Step 1: Rough Grinding with 80# Water Sandpaper

1 . Preparation:

- Water is applied to the surface

- 80# water sandpaper is used manually for controlled grinding

2 . Technique:

- Light pressure and steady back-and-forth strokes ensure effective material removal

- Periodic wiping and side-view inspection help monitor progress

3 . Purpose:

- Eliminates marks left by saw blades

- Shapes contours and levels out irregularities for precision

4 . Best Practices:

- Maintain proper technique to avoid overgrinding

- Ensure a smooth, even foundation for subsequent polishing steps

This initial rough grinding stage is critical in determining the final quality and luster of the stone. Only with precision in this step can a truly high-end polished finish be achieved.

🌟 Why Choose White Marble Limestone from PurchaseStones?

- ✅ Architect-approved for modern and high-performance construction

- ✅ Naturally elegant and thermally stable

- ✅ Versatile in both design and structural applications

- ✅ Finely processed using expert craftsmanship

From modern facades to legacy architecture, our white marble limestone represents the ideal combination of strength, sustainability, and beauty.

Share