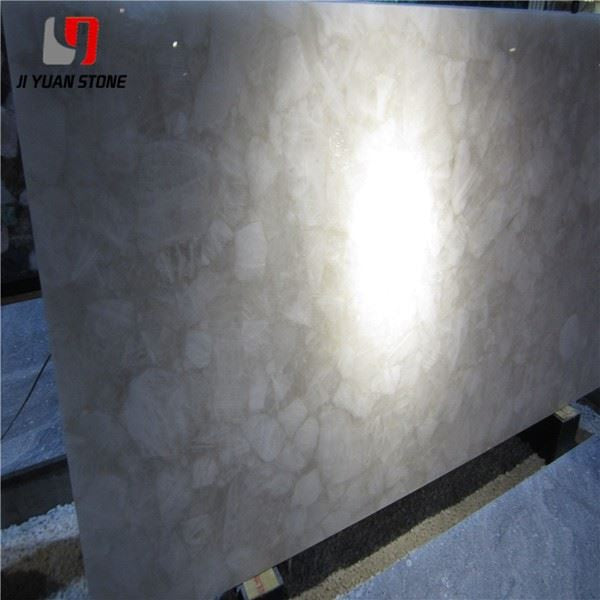

White Crystal Gemstone Slab

White Crystal Gemstone Slab

White Crystal Gemstone Slab – Luxury Stone for Elegant Interiors

Crafted from pure white crystal, this gemstone slab boasts an elegant and pristine appearance. Its natural beauty is perfect for adding a touch of glamour to any space. With a high level of durability and versatility, this slab is perfect for a variety of decorative and functional uses.

| Feature | Details |

|---|---|

| Product Name | White Crystal Gemstone Slab |

| Surface Finished | Honed,Polished |

| Color | Yellow,Black,White,Red,Purple Wood,Green,Grey,Pink,Rainbow,Pink,Tiger Eye etc |

| Advantage |

(1)Big hardness (2)Very durable (3)Strong corrosion resistance (4) High-temperature resistance (5)Non-toxic and non-radioactive (6)Low cost |

| Usage | Interior & Exterior Decoration. Be widely used in countertops, washing basins, and bar counters, and also suitable for exterior wall panelling, flooring and etc. |

| Small slab |

1800(up)×60-90(up)mm Thickness: 15mm, 18mm, 20mm and etc |

| Big slab |

2400(up)×120(up)mm Thickness: 20mm, 30mm and etc |

| Cut to size |

300 x 300mm, 600 x 600mm, 800 x 800mm and etc Thickness:10mm, 15mm, 18mm, 20mm and etc |

| Kitchen countertop |

96" x 25.5", 108" x 26", 96" x26", 108" x 25" and etc Thickness: 20mm;30mm;20mm+20mm laminate and etc |

| Island top | 96"x36",108"x36",96"x40",72"x36" and etc |

| Vanity top | 31"x22",37"x22",49"x22",61"x22",73"x22" and etc |

| Stair step&riser | 1000-1300x300x20/30mm & 1000-1300x150x20mm |

| Quality control |

(1)Standard Exporting Seaworthy Package ( Inner: plastic film and foam; Outer: Solid Wood crates or pallets.) (2) Color Difference Control (3) Thickness tolerance:+/-0.5mm,+/-1mm |

| MOQ | Welcome Small Trail Orders |

| Sample | Contact Us For Free Samples |

| Payment | T/T, L/C, Escrow, Western Union |

| Delivery | Within three weeks after Confirmation |

White crystal gemstone slabs are a premium choice for creating sophisticated and timeless interiors. Known for their natural brilliance, elegant patterns, and smooth texture, these slabs are widely used for wall cladding, flooring, columns, and high-end decorative applications. Their translucent appearance adds a sense of depth and refinement to any space, making them a popular option in modern architecture and luxury home design.

When choosing white crystal gemstone slabs, it is essential to follow proper planning and installation practices to ensure both aesthetic beauty and long-lasting performance. Below are the key guidelines for white crystal gemstone slab selection and planning:

1. Stone Selection & Color Coordination

- For the same project, always use slabs from the same mine source and the same layer of rock to maintain consistent color and pattern across all decorative surfaces.

- Natural white crystal slabs with the same name can still vary in tone and pattern.

- To achieve color uniformity, select two standard samples (minimum 200×300mm) to establish the upper and lower limits of color control and acceptance standards.

2. Texture Direction & Processing

Always mark the direction of stone texture when planning veneer layouts to ensure alignment.

Prepare a stone processing map for main areas and critical parts to avoid mismatched patterns.

Factories should strictly follow regulations for:

- Color selection

- Typesetting

- Size proofreading

3. Deformation Joints & Seam Planning

Panels used at deformation joints (such as seismic, expansion, or settlement joints) must ensure both structural flexibility and a seamless visual appearance.

For uniformity in the same space (walls, floors, and ceilings), follow either:

- Through seams for continuous flow, or

- Regularly connected seams for a structured look.

4. Usage Limitations

- White crystal gemstone slabs are not suitable for outdoor use.

- Avoid installation in environments exposed to acidic materials, as it may damage the stone.

5. Planning Stone Veneer for Walls & Columns

Modulus Coordination: Ensure the stone veneer dimensions align with the building’s modular measurements, especially near doors, windows, openings, and carved elements. Avoid using narrow strips smaller than ½ the standard width.

Joint & Block Coordination: For walls and columns made of the same material, maintain consistent block sizes and joint alignments (both horizontal and vertical).

Corner Placement:

- Outer corners should always have full-sized (complete modulus) slabs.

- Inner corners can use cut pieces when necessary.

✅ Why Choose White Crystal Gemstone Slabs?

- Elegant Appearance: Adds luxury and sophistication to modern interiors.

- Durability: High strength for long-lasting applications in walls, flooring, and cladding.

- Versatility: Suitable for residential, commercial, and hospitality projects.

- Premium Quality: Carefully processed and quality-checked for flawless finishing.

Enhance your interiors with White Crystal Gemstone Slabs – a perfect combination of natural beauty, durability, and refined elegance. Ideal for projects that demand premium aesthetics and meticulous detailing.

👉 Browse our exclusive collection of white crystal gemstone slabs at Purchase Stones and transform your interiors with timeless luxury.

Share