Ultra Thin Stone Panels

Ultra Thin Stone Panels

Ultra Thin Stone Panels – Lightweight, Affordable, and Flexible Cladding for Modern Construction

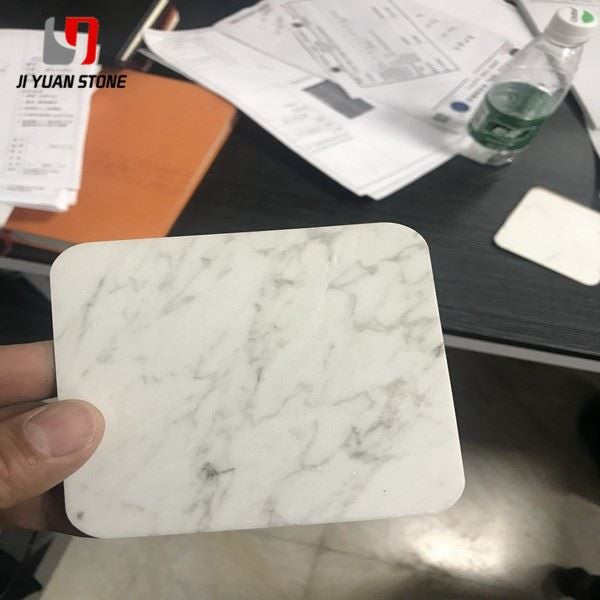

Introducing Ultra Thin Stone Panels-the future of home design. Made from real stone, these panels are ultra-thin and lightweight, making them easy to install and versatile for any project. With their natural beauty and durability, these panels are a cost-effective and sustainable choice for your next renovation.

| Feature | Details |

|---|---|

| Product | Ultra thin stone panels |

| Surface | Polished,Honed |

| Thickness | 1mm-3mm |

| Finished Products | Floor tiles, Wall cladding etc |

| Colour | Many colors available |

| Sheet size |

|

| Chip size |

|

| Surface finished |

|

| Mosaic pattern |

|

| Application |

Wall & Floor, Interior/Exterior projects, Kitchen backsplash, Bathroom flooring, Shower surround, Countertop, Dining room, Entryway, Corridor, Balcony, Spa, Pool, Fountain, etc. |

| Packing |

|

The Ultra Thin Stone Panels are an ideal solution for architects, builders, and designers seeking a balance of aesthetic appeal, lightweight construction, and economical installation. Crafted from genuine stone, these panels provide the natural texture and beauty of stone while minimizing the structural burden often associated with traditional cladding materials.

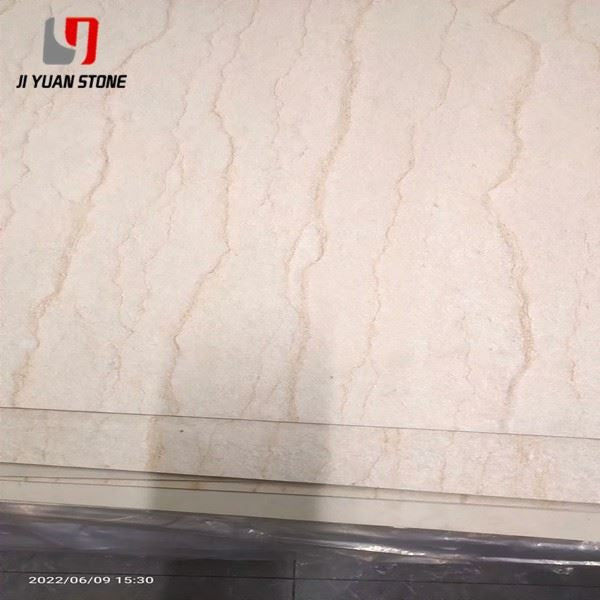

With a reduced thickness and lightweight form, Ultra Thin Stone Panels are perfect for both interior and exterior wall cladding, particularly in high-rise or large-format architectural applications. They offer ease of installation and cost efficiency while delivering high-end results.

✅ Key Advantages of Ultra Thin Stone Panels

- 💰 Low Cost & High Efficiency: These panels are budget-friendly and simplify construction with reduced labor time and minimal structural reinforcement.

- 🔧 Easy Installation: Designed for quick mounting, making them ideal for fast-paced commercial or residential projects.

- 🔄 Flexible Point Layout: Supports multi-point configurations, allowing better load distribution and adaptability for larger panels.

- 🏢 Suitable for Large Plates: Their structure is optimized for wide-span installations, providing a seamless and clean look on large surfaces.

⚠️ Important Considerations and Limitations

While the advantages are clear, it's essential to understand the potential shortcomings and technical complexities associated with Ultra Thin Stone Panels:

1. Installation Challenges & Safety Concerns

- 📉 The dead weight is supported primarily by the bottom two pick points, which may lead to vertical force transmission when displacement occurs.

- 🪛 For oversized panels, additional mid-back support is necessary, typically achieved by cutting deep grooves and attaching “I”-shaped pendants with adhesive. However, the bonding quality is hard to verify.

- 🪚 Grooving the stone to insert pendants requires a minimum stone thickness of 25mm, which adds to the overall weight.

2. Back Bolt Connection Issues

- 🔍 Back bolt drilling quality is difficult to inspect, and poor workmanship can lead to anchor pull-out or safety hazards.

- 🔩 Tightening control is inconsistent, which may reduce the panel’s overall structural integrity.

- 🧱 Small anchor-to-stone contact surface requires the use of thicker stone panels, increasing both material cost and weight unnecessarily.

- 💥 In materials like basalt glass stone, improper expansion of the back bolt’s ring can lead to cracks or panel bursts due to stress concentration.

✅ Conclusion

The Ultra Thin Stone Panels offer a modern, lightweight, and cost-effective alternative to traditional cladding systems. Their easy installation, natural stone aesthetics, and flexible design make them a top choice for many projects. However, when used in complex or large-scale applications, careful attention must be paid to installation quality, anchor methods, and panel thickness to ensure safety and longevity.

For optimal performance, we recommend professional installation and thorough quality control throughout the construction process.

Share