Tumbled Travertine Tile

Tumbled Travertine Tile

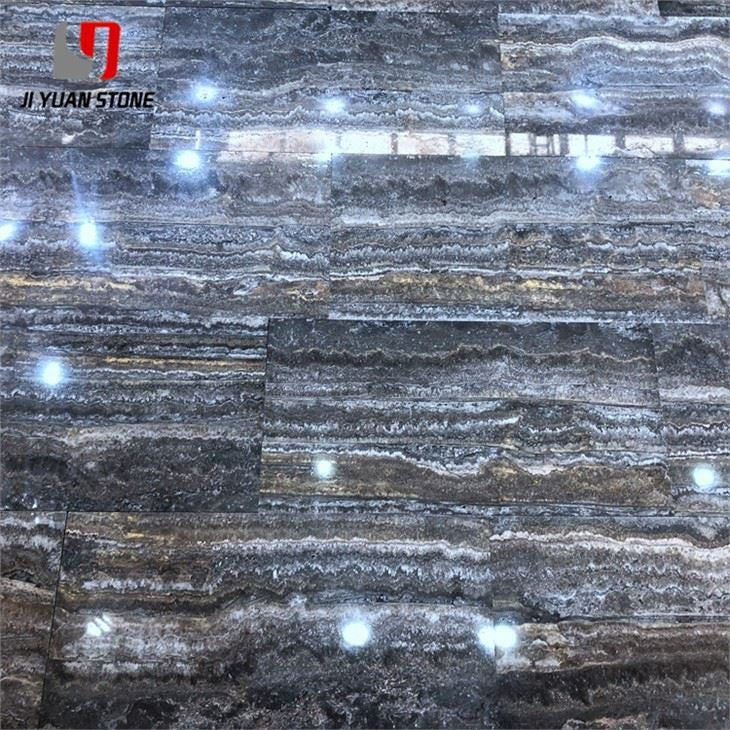

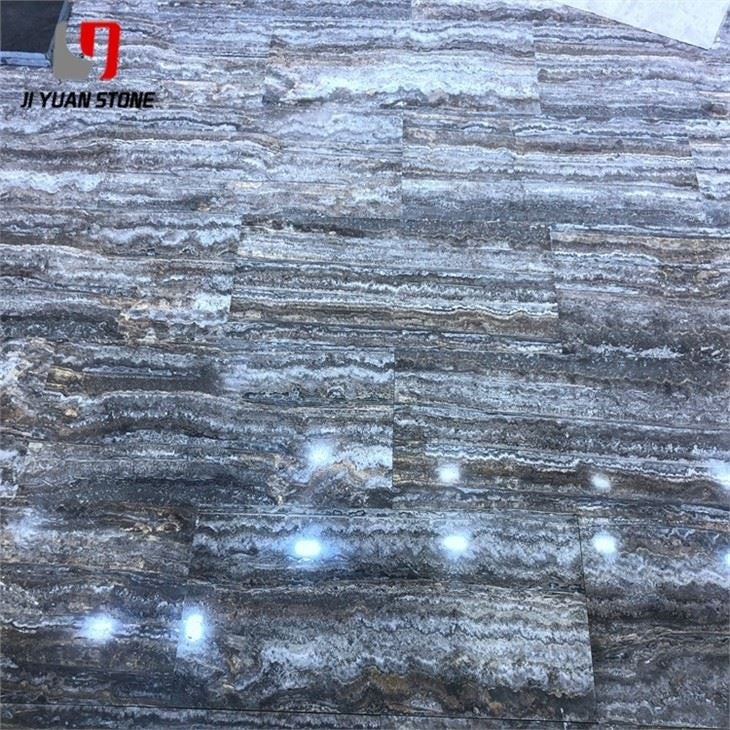

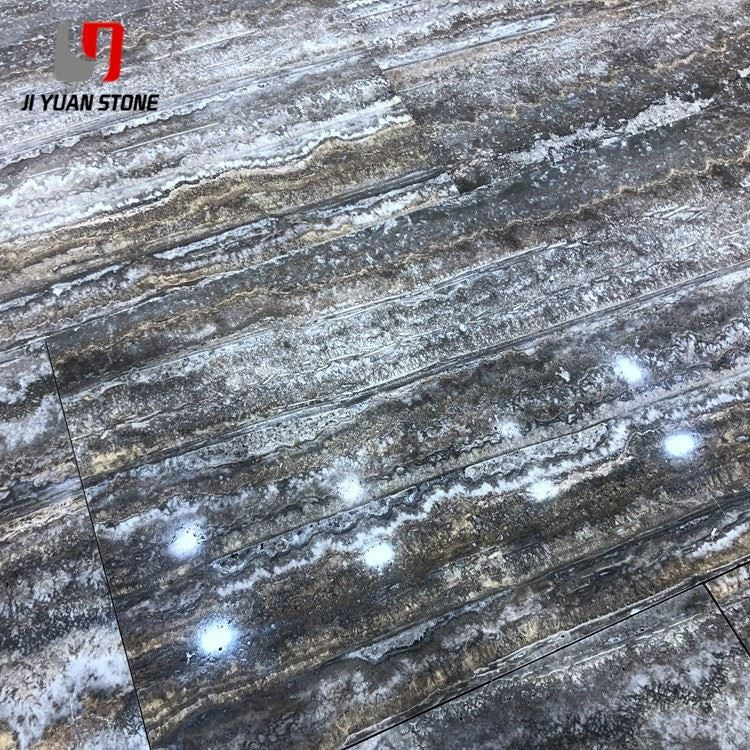

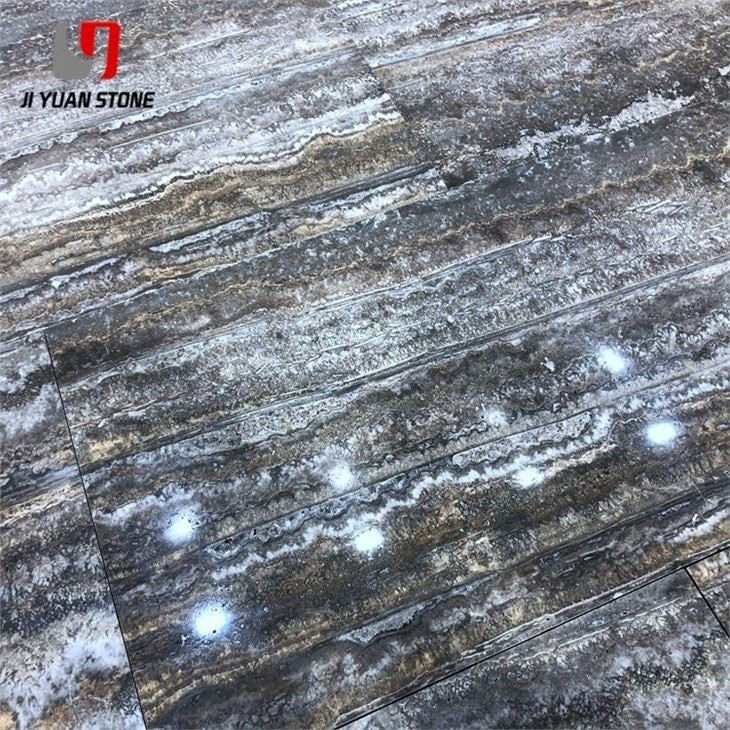

Tumbled Travertine Tile – Rustic Texture, Lasting Beauty

This tumbled travertine tile offers a durable and stylish option for flooring and wall tiling. With its natural and unique patterns, it adds character and sophistication to any space. Made with high-quality materials, it is long-lasting and easy to maintain. Elevate your home or business with tumbled travertine tile.

| Feature | Details |

|---|---|

| Material | Natural travertine |

| Colour | Silver, Grey |

| Thickness | 15mm , 16mm , 18mm , 20mm or customized |

| Slab sizes |

|

| Tile sizes | 300x300mm ; 600x600mm; 450x450mm etc |

| Surface | Polished |

| Edge processing | Machine cutting, round edge etc |

| Packing | Seaworthy wooden crate, pallet |

Tumbled Travertine Tile brings timeless charm and rugged beauty to any space. Its naturally weathered surface and soft edges make it ideal for both classic indoor flooring and elegant outdoor designs. With high porosity and unique texture, these tiles offer a natural, slip-resistant surface perfect for homes, commercial buildings, patios, and hallways.

⚠️ Common Issues with Tumbled Travertine Tile & How to Prevent Them

In modern architecture, many buildings use tumbled travertine tile and granite to enhance floor aesthetics. However, due to high porosity and water absorption, unprotected travertine is vulnerable to damage—especially under heavy foot traffic, natural weathering, and exposure to environmental pollutants.

Uncured or untreated tiles can lead to:

- Yellowing and discoloration

- Efflorescence (white salt deposits)

- Surface grain explosion

- Fluffing or pitting

- Macula (stain) formation

🏢 Real-World Case Study: 28-Story Commercial Building

In Shanghai, a commercial tower finished with beige tumbled travertine tile faced serious surface damage only one year after completion. The building's floor was covered in efflorescent white patches and visible gray macula. The granular texture indicated grain loosening and board bursting.

By the time experts were contacted, the surface had deteriorated further:

- Efflorescence turned into wide-scale yellow and brown macula

- Surface pits appeared—some as large as fingernails

- Grain damage led to visible craters across the floor

🛠️ Why Standard Construction Sequences Fail

Initial restoration followed this sequence:

Stain Removal → Grinding → Hole Repair → Waterproofing

However, this sequence proved ineffective, as:

- Improper grinding loosened already weakened surfaces

- Early polishing led to glue falling off during repair

- Water-based sealers trapped moisture, worsening stains

🔧 Correct Construction & Maintenance Approach

To ensure long-term durability and natural finish, use the following expert method:

1 . Assess Surface: Identify macula, efflorescence, and grain loosening.

2 . Dry Thoroughly: Ensure no moisture remains before any repair or sealing.

3 . Use Deep-Penetrating Reinforcement Agents: They should be hydrophilic, non-discoloring, and strongly adhesive.

4 . Stain Removal: Apply proven non-damaging cleaners in targeted areas.

5 . Grind Gently: Open surface pores carefully using 50#-3000# abrasives.

6 . Repair Holes: Match colors with high-strength adhesive. Polish only after curing.

7 . Waterproof Properly: Apply breathable, solvent-based sealers to protect without discoloration.

8 . Maintain Regularly: Clean with neutral pH solutions, avoid acidic or abrasive products.

🧼 Daily Cleaning & Prevention Tips

- Wipe spills immediately to avoid staining

- Use a damp mop with a neutral cleaner

- Avoid harsh acids like vinegar, cola, wine, or citrus-based agents

- Apply a quality stone sealer every 6–12 months

- Place mats or rugs in high-traffic areas

✅ Why Choose Our Tumbled Travertine Tile?

- Naturally tumbled texture for a rustic, aged look

- Slip-resistant and durable for indoor and outdoor use

- Expert-recommended maintenance guidance

- Ideal for vintage, Mediterranean, and classic aesthetics

- Tested for performance in high-traffic environments

Enhance your space with the character and warmth of Tumbled Travertine Tile—crafted by nature, perfected with care.

Share