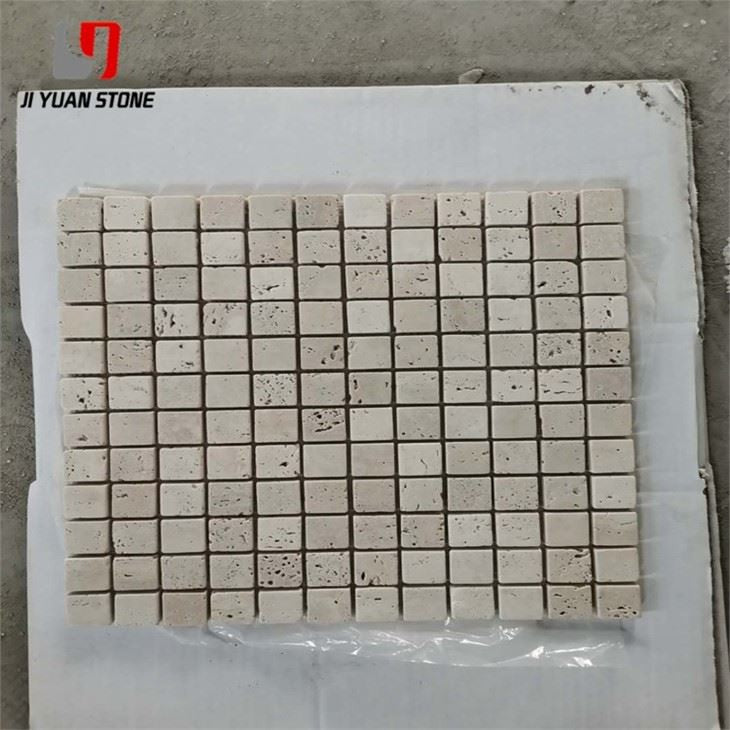

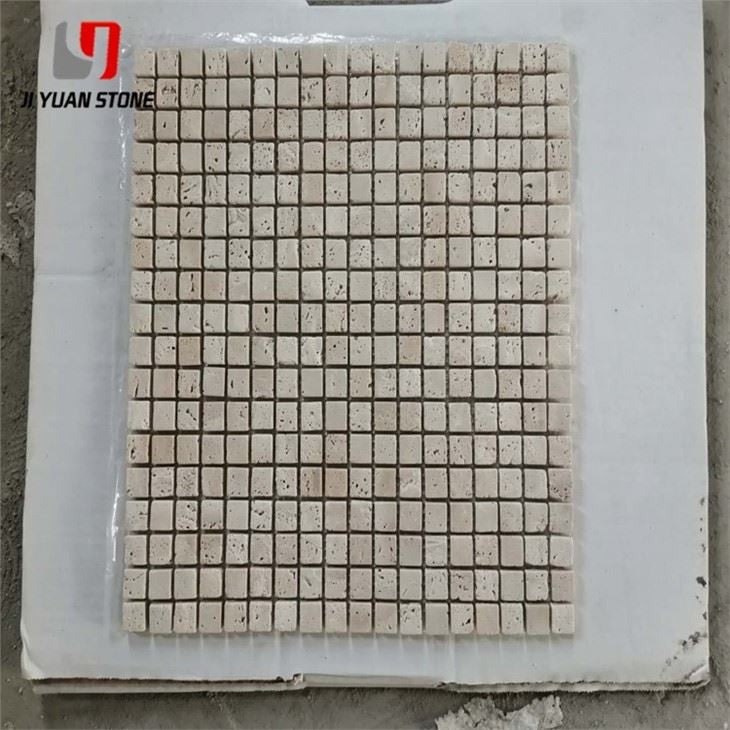

Tumbled Travertine Mosaic Tiles

Tumbled Travertine Mosaic Tiles

Enhance the beauty of your home with our Tumbled Travertine Mosaic Tiles. Made from high-quality travertine, these tiles are durable and long-lasting. Create a stunning backsplash, accent wall, or floor design with the natural and unique patterns of these tiles. Perfect for any room in your home, they add a touch of elegance and sophistication.

| Feature | Details |

|---|---|

| Material | Natural Marble Stone,Travertine,Limestone |

| Colour | As pictures show or customized |

| Shape | Square, Basketweave, Mini brick, Modern brick, Herringbone, Subway, Hexagon, Octagon, Mixed, Grand fan, Penny round, Hand clipped, Tesserae, Random strip, River rocks, 3D cambered, Pinwheel, Rhomboid, Bubble round, Circle bubble, Stacked, etc... |

| MOQ | Unrestricted |

| Warranty | 3 years |

| After-sale Service | Online technical support |

| Size | Customized Size |

| Style | Modern |

| Occasion | Wall or Floor |

| Project Solution Capability | Total solution for projects |

| Application | Bathroom |

| Design Style | Modern |

| Place of Origin | China |

| Model Number | Brass Marble Waterjet Mosaic |

| Shape | Irregular |

Flatness Polishing Construction of Tumbled Travertine Mosaic Tiles

Polishing Tumbled Travertine Mosaic Tiles differs from polishing large slabs due to factors like gravity, screwing force, and grinding resistance. The primary focus is on flatness grinding and corner polishing.

1️⃣ Flatness Polishing Construction Process

🔹 Step-by-Step Procedure:

- Flatness Polishing

- Inspection & Repair

- Brushing with Waterproofing Agent

- Middle Polishing

- Brushing with Waterproofing Agent

- Fine Polishing

- Polishing

- Cleaning

- Crystallization

2️⃣ Flatness Grinding – Equipment & Process

✅ Grinding Equipment & Speed

- Use a floor scrubber with a minimum speed of 160 RPM.

- Avoid excessive force to prevent damage.

✅ Grinding Materials

- Diamond grinding discs should be used to prevent collisions with mosaic particles.

✅ First Road Polishing

- Experienced workers should perform the first sanding process.

- Maintain even grinding, allowing minor low-depressed particles.

- Flatness target: 85%–90%.

- Post-first-polishing: Clean, dry, and repair peeled seam glue.

✅ Polishing for Standardized Mosaic Floors

- Mosaics with standardized particles and gaps can be polished with a 50-mesh polishing pad.

✅ Waterproofing & Final Sanding

- Subsequent waterproofing and grinding follow the standard slab polishing process.

3️⃣ Trimming & Edge Polishing

🔹 Key Considerations for Edge Polishing:

- Corners require cutting to fit vacant spaces, causing threshing and sparse particles.

- Glue filling at edges should be temporarily suspended until particles are properly filled.

-

Grain Filling Process:

- Fill sparse grains (including half grains).

- Apply rubber material.

- Grind for uniformity.

🔹 Edge Grinding Challenges:

- Large grinding surface height differences cause noticeable wear marks at corners.

- Extensive manual grinding is required to balance the surface.

By following these precise construction steps, the flatness, durability, and aesthetics of Tumbled Travertine Mosaic Tiles are optimized for long-lasting results. ✅

Share