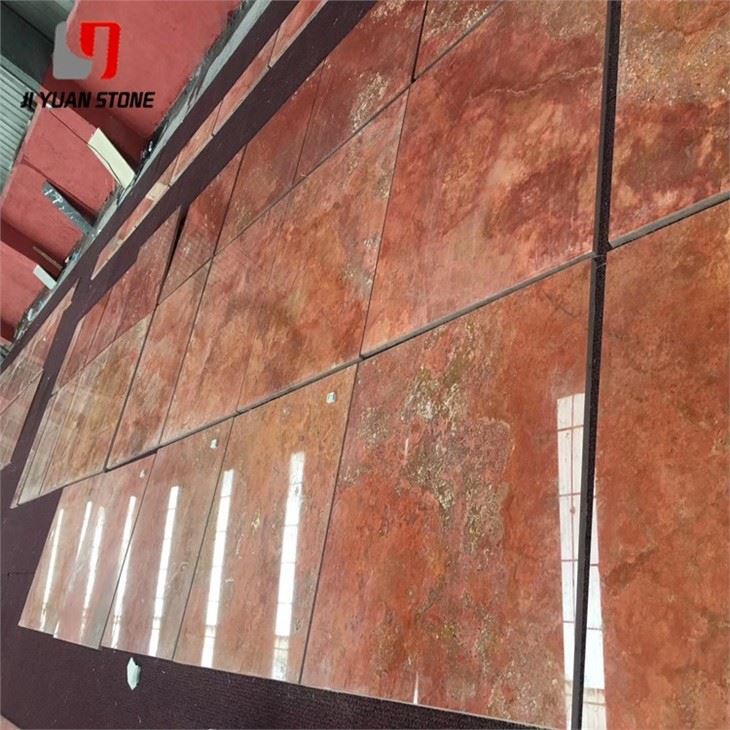

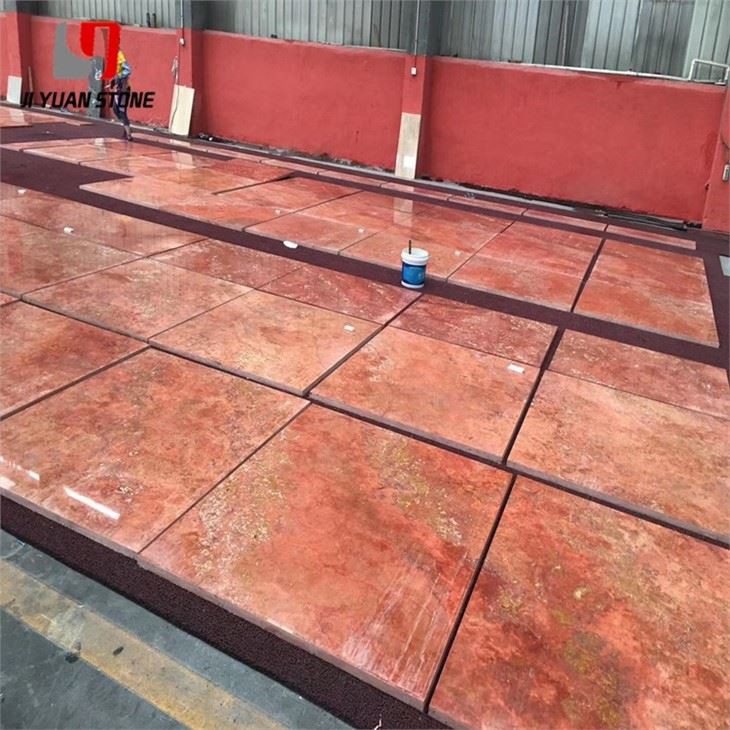

Travertine Stone Flooring

Travertine Stone Flooring

Travertine Stone Flooring – Certified Quality, Elegant Finish, Lasting Durability

This Travertine Stone Flooring offers a durable and stylish flooring option for any space. Made of natural stone, it provides a unique and elegant appearance while also being highly resistant to wear and tear. Perfect for both indoor and outdoor use, it is a versatile and long-lasting choice.

| Feature | Details |

|---|---|

| Item: | Travertine Tiles, Cut-to-size, Slabs |

| Popular tile size: |

|

| Popular small (half) slab size: |

|

| Popular big slab size: |

|

| Usual Thickness: | 1.0cm, 1.5cm, 1.8cm, 2cm, 3cm, 4cm, 5cm, 6cm etc.. |

| Finished: | Polished |

| Package: | By strong fumigated wooden crates, wooden pallets, wooden bundles, etc.. |

| Samples | FREE SAMPLES will be provided once request |

Upgrade your interiors or outdoor spaces with travertine stone flooring—a timeless material known for its natural beauty, strength, and versatility. At Purchase Stones, we supply travertine flooring that not only enhances aesthetics but also complies with the highest quality inspection and acceptance standards.

Our travertine stone flooring undergoes rigorous testing, ensuring each slab meets both national and internal performance benchmarks.

🔍 Travertine Stone Flooring: Quality Inspection and Acceptance Standards

✅ 4.4 Appearance Quality

4.4.1 Visual Inspection Criteria:

- Tonal Pattern & Weathering are assessed visually to ensure uniformity and visual appeal.

- Hard Minerals are checked on the surface through manual inspection.

4.4.2 Defects in Edges and Corners:

- Missing edges and corners are measured using steel tape for accuracy.

- Measurements include length, width, and depth of any defects.

4.4.3 Crack Detection Methods:

- Visual Inspection: Direct surface evaluation.

- Water Pouring Method: Water is poured to observe penetration into cracks.

- Hammering Method: Detects internal structural weakness by identifying hollow sounds.

- Crack length is measured using steel tape for precise data.

✅ 4.5 Physical Properties

4.5.1 Volume Density & Water Absorption

- Tested as per GB9966.3 standards to ensure material stability.

4.5.2 Dry Compressive Strength

- Measured according to GB9966.1, verifying the flooring’s load-bearing capacity.

4.5.3 Bending Strength

- Determined using GB9966.2, ensuring the stone’s ability to withstand pressure and stress.

✅ 4.6 Acceptance Criteria

- The minimum size of each slab is used to calculate usable volume.

✅ 4.7 Size Representation

- All dimensions are based on the smallest side of the travertine slab to ensure consistency in layout planning.

📦 5. Inspection Rules

✅ 5.1 Outlet Inspection

5.1.1 Inspection Items:

- Size deviation, flatness, angle accuracy, and appearance quality.

5.1.2 Batch Definition:

- Each batch includes travertine flooring of the same color tone, pattern, category, and grade—measured per 5m³.

- 5.1.3 Inspection Method:

- Every slab is inspected individually for compliance.

5.1.4 Quality Judgment:

- Accepted if all quality parameters pass.

- Rejected if any single parameter fails.

✅ 5.2 Type Inspection

5.2.1 Scope:

- Covers all parameters listed in technical standards.

5.2.2 Trigger Events:

- New mine operations, significant tone variation, biannual inspections, or national agency requests.

5.2.3 Batch Definition:

- Follows the same criteria as ore inspections.

5.2.4 Methodology:

- Visual inspections for surface and edge quality.

- Physical tests on randomly selected blocks per GB9966.1 to GB9966.3.

5.2.5 Judgment Criteria:

- If any physical performance test (density, strength, absorption) fails, the entire batch is rejected.

🌟 Why Choose Travertine Stone Flooring from Purchase Stones?

- Premium-grade slabs with rich natural texture

- Scientifically tested for long-term durability

- Accurate sizing and smooth finish for seamless installation

- Ideal for both residential and commercial use

- Quality assurance as per national and international standards

Make a lasting investment with high-quality travertine flooring—where elegance meets strength, and every piece is quality-certified.

✔️ Available in multiple tones, sizes, and finishes

✔️ Delivered worldwide with inspection-ready quality

Share