Travertine Natural Stone

Travertine Natural Stone

Travertine Natural Stone Blocks – Certified Quality for Structural & Decorative Applications

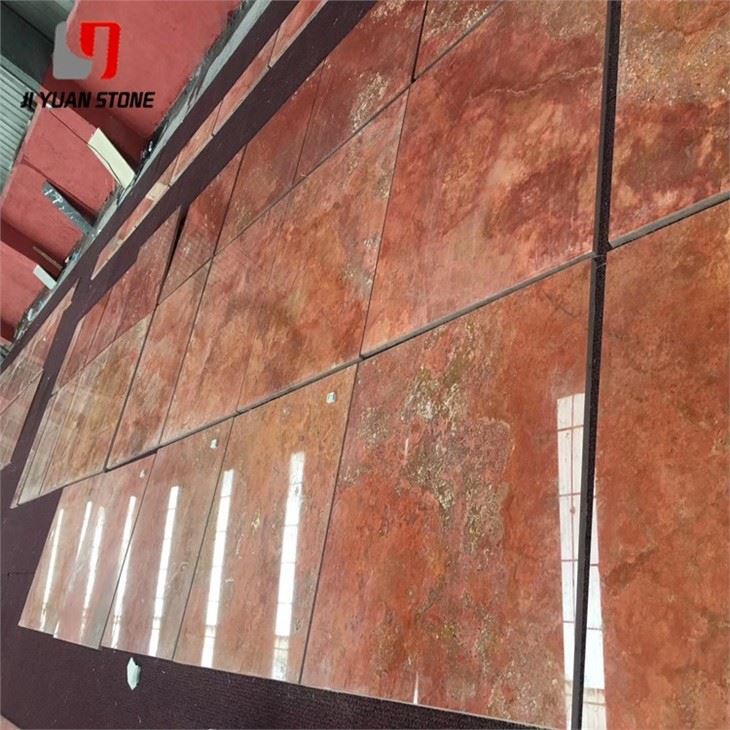

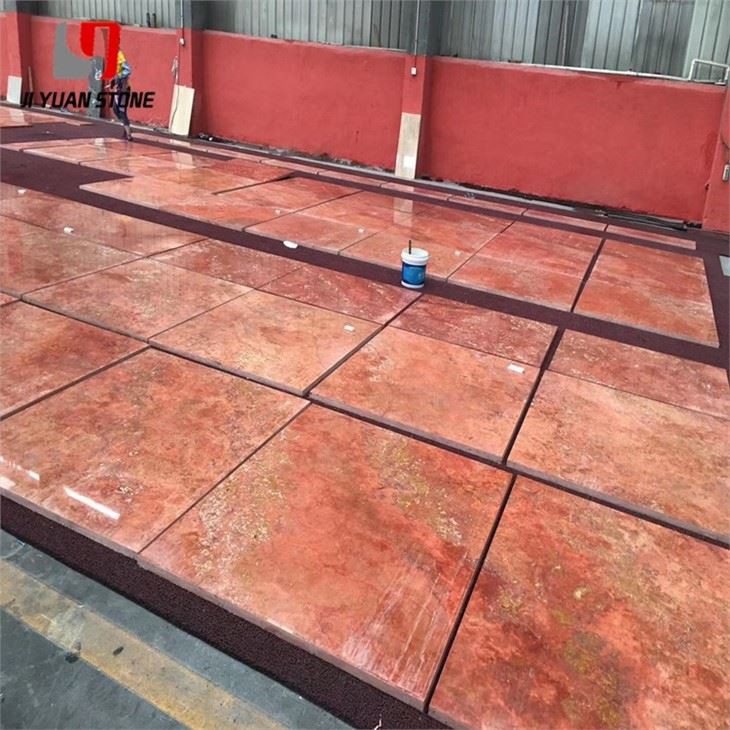

This travertine natural stone offers a durable and timeless option for your home design needs. With its natural variations in color and texture, it adds a touch of elegance and sophistication to any space. Made from the highest quality materials, it is a long-lasting and beautiful choice.

| Feature | Details |

|---|---|

| Item: | Travertine Tiles, Cut-to-size, Slabs |

| Popular tile size: |

|

| Popular small (half) slab size: |

|

| Popular big slab size: |

|

| Usual Thickness: | 1.0cm, 1.5cm, 1.8cm, 2cm, 3cm, 4cm, 5cm, 6cm etc.. |

| Finished: | Polished |

| Package: | By strong fumigated wooden crates, wooden pallets, wooden bundles, etc.. |

| Samples | FREE SAMPLES will be provided once request |

Travertine natural stone blocks are premium-grade building materials extracted from rich travertine ore bodies. Known for their durability, elegant surface patterns, and versatile use, these blocks are ideal for producing high-end cladding, wall surfaces, and architectural elements.

At Purchase Stones, we supply travertine natural stone blocks that meet stringent classification, technical standards, and testing protocols to ensure performance, precision, and quality.

📘 Travertine Natural Stone Blocks: Classification, Technical Standards & Testing Methods

✅ 1. Subject Content & Scope of Application

This standard outlines the classification, technical requirements, test methods, inspection rules, marking, transportation, and storage procedures for travertine blocks.

Application Scope:

- Includes blocks used for construction and surface material production.

- Derived from natural travertine stone ore bodies.

🪨 2. Product Categories

2.1 Classification by Shaping Method:

-

Saw-Faced Blocks (SS):

All six faces are shaped via sawing for dimensional precision. -

Splitting Blocks (CS):

One or more faces shaped using chiseling for a more rustic appearance.

2.2 Grading System:

-

First-Class Product (B):

High dimensional accuracy and superior surface quality. -

Qualified Product (C):

Acceptable for most building applications, with minor tolerances.

2.3 Naming and Labeling:

-

Naming Order:

(Place of origin) + (Color pattern) + Travertine Natural Stone (M) -

Marking Sequence:

Classification + Size + Grade + Standard Number

📏 3. Technical Requirements

3.1 Block Shape:

Blocks must be right-angled parallelepipeds (rectangular cuboids) for ease of stacking, cutting, and finishing.

3.2 Dimensions:

Blocks must comply with specified sizing standards to ensure uniformity and consistency in large-scale applications.

🔬 4. Test Methods

4.1 Dimensional Difference Measurement:

- Tool: Steel tape (1mm scale)

- Accuracy: Readings taken to the nearest 1cm

- Measures: Length, width, height – maximum difference indicates dimensional tolerance

4.2 Flatness Test:

- Tool: 1m steel flat ruler (tolerance: 0.1mm)

- Procedure: Measure the maximum gap between ruler and surface

- Output: Gap represents flatness limit tolerance

4.3 Angle Measurement:

Tool: 90° steel square (accuracy: 0.13mm)

Procedure:

- Use the flattest block face as reference

- Measure deviation at 40cm from the base if angle < 90°

- Largest deviation is recorded as angle tolerance

🔎 Quality Assurance & Inspection Standards

All blocks undergo strict inspection and are individually assessed for:

- Size deviation

- Surface flatness

- Angular accuracy

- Appearance quality

Each batch is grouped by color tone, pattern, category, and grade, following industry-standard protocols.

🏗️ Why Choose Our Travertine Natural Stone Blocks?

- Extracted from premium travertine ore bodies

- Certified according to industry-standard testing methods

- Available in multiple finishes and sizes

- Ideal for cutting into tiles, slabs, cladding, and other architectural forms

- Delivered with inspection-ready documentation

Bring strength, sophistication, and certified precision to your next architectural project with Purchase Stones' Travertine Natural Stone Blocks.

✔️ International shipping available

✔️ Custom sizing on request

✔️ Technical documentation provided for bulk orders

Share