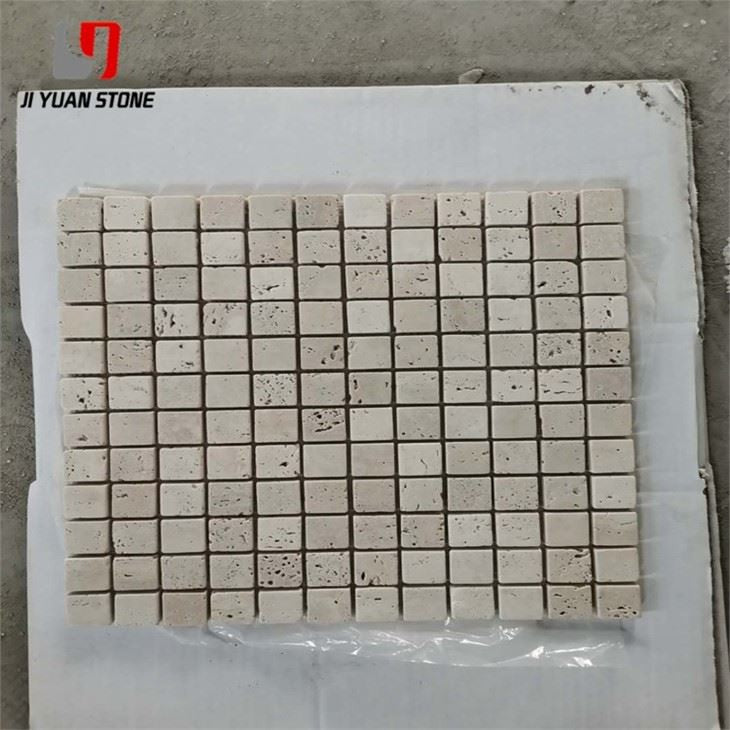

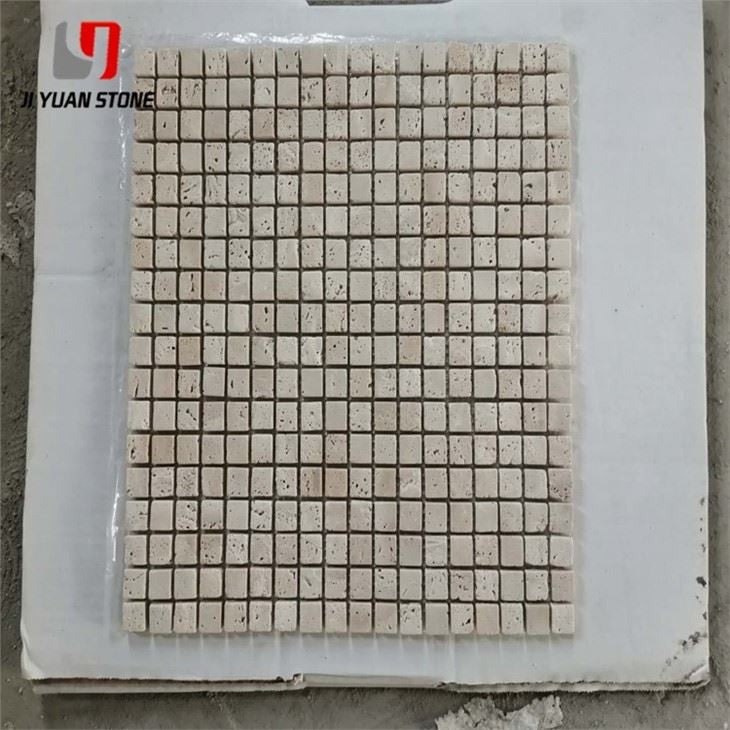

Travertine Mosaic Wall Tiles

Travertine Mosaic Wall Tiles

Discover the timeless beauty of our Travertine Mosaic Wall Tiles. Crafted from premium quality travertine, these tiles add a touch of elegance to any space. With their durable and versatile nature, our tiles are perfect for enhancing the look of your walls and providing long-lasting beauty.

| Feature | Details |

|---|---|

| Material | Natural Marble Stone,Travertine,Limestone |

| Colour | As pictures show or customized |

| Shape | Square, Basketweave, Mini brick, Modern brick, Herringbone, Subway, Hexagon, Octagon, Mixed, Grand fan, Penny round, Hand clipped, Tesserae, Random strip, River rocks, 3D cambered, Pinwheel, Rhomboid, Bubble round, Circle bubble, Stacked, etc... |

| MOQ | Unrestricted |

| Warranty | 3 years |

| After-sale Service | Online technical support |

| Size | Customized Size |

| Style | Modern |

| Occasion | Wall or Floor |

| Project Solution Capability | Total solution for projects |

| Application | Bathroom |

| Design Style | Modern |

| Place of Origin | China |

| Model Number | Brass Marble Waterjet Mosaic |

| Shape | Irregular |

Grouting and Reinforcement Construction Process for Travertine Mosaic Wall Tiles

1️⃣ Multi-Step Grouting Process

✅ Importance of Multi-Step Grouting

- One-time filling is not recommended as thick glue may trap solvents inside, causing the surface to harden while the lower layer remains soft.

- The correct process involves grouting, curing, regrouting, and recuring to ensure proper adhesion and strength.

✅ Final Filling for Shrinkage

- If colloid shrinkage is significant, apply a third layer of glue.

- Use polished joint sealant for larger cavities and leaks.

2️⃣ Grouting Reinforcement Construction Steps

✅ Step-by-Step Process

- Surface Cleaning

- Brushing with Oil-Repellent Material

- First Thin Glue Filling & Curing

- Second Glue Filling & Curing

- Surface Inspection & Repairs

- Final Curing

3️⃣ Detailed Construction Steps

✅ (1) Surface Cleaning

- Remove all floating dust using a vacuum cleaner with a brush head.

- The brush helps weaken suction, preventing damage to the travertine mosaic wall tiles while ensuring clean gaps for better glue adhesion.

✅ (2) Coating Oil-Proof Protective Material

- Different joint glues and stone particles can lead to oil seepage and discoloration.

- Apply oil protection to prevent stains.

- Quick-drying acrylic resin (special preparation required) is recommended.

✅ (3) Diluting & Matching Joint Potting Glue

- The first pour of grouting glue should be diluted to allow deep penetration into primer pores and tight joints.

-

Control factors:

- Penetration time

- Curing time

- Shrinkage rate

✅ (4) Color Matching the Grout

- Travertine mosaic wall tile gaps require careful grout color selection.

- The grout color should highlight the stone’s texture while ensuring a harmonious overall appearance.

-

Approval Process:

- The general contractor and owner should approve the final grout color.

- A sample model should be prepared for selection, as shown in Figure 6.

- Ensure uniform color consistency between liquid glue and caulking glue.

Final Thoughts

By following these precise grouting and reinforcement steps, travertine mosaic wall tiles achieve:

✅ Stronger adhesion

✅ Better aesthetic integration

✅ Minimal shrinkage & surface defects

✅ Increased durability & longevity

This step-by-step approach guarantees a high-quality finish with lasting structural integrity. ✅

Share