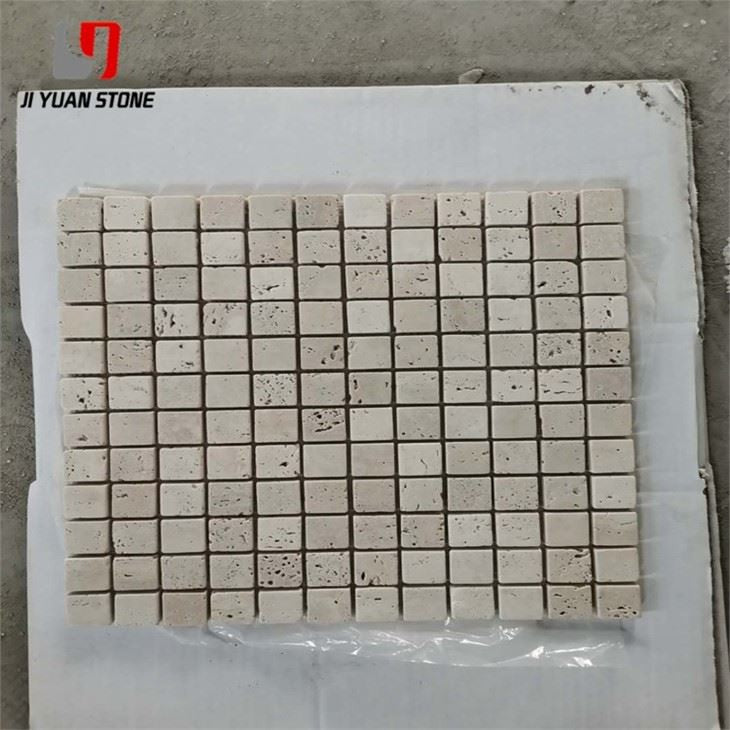

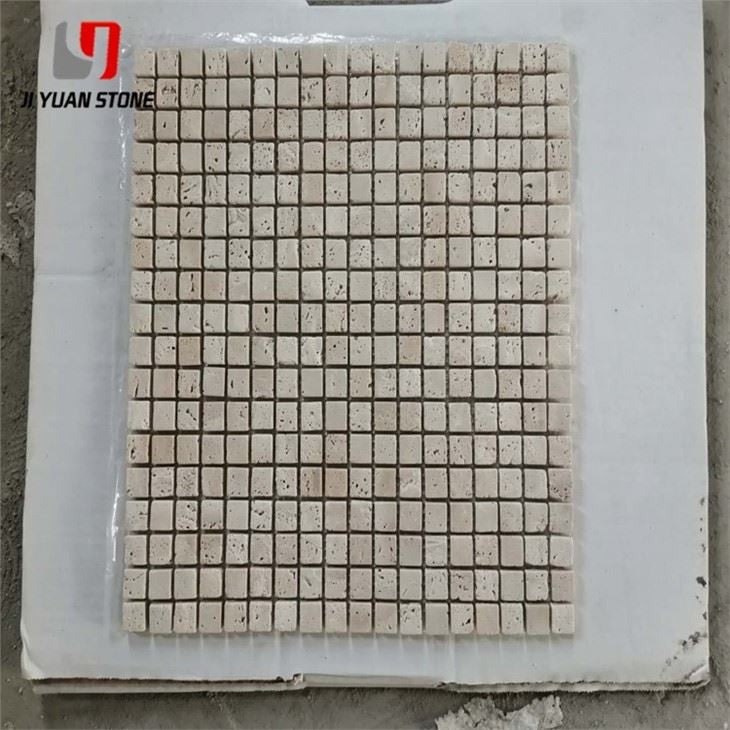

travertine mosaic tile sheets

travertine mosaic tile sheets

Enhance your space with our travertine mosaic tile sheets. Made with high-quality travertine, these sheets provide a durable and stylish option for your flooring or backsplash needs. Each sheet is expertly crafted, making installation a breeze. Elevate your design with these timeless and elegant tiles.

| Feature | Details |

|---|---|

| Material | Natural Marble Stone,Travertine,Limestone |

| Colour | As pictures show or customized |

| Shape | Square, Basketweave, Mini brick, Modern brick, Herringbone, Subway, Hexagon, Octagon, Mixed, Grand fan, Penny round, Hand clipped, Tesserae, Random strip, River rocks, 3D cambered, Pinwheel, Rhomboid, Bubble round, Circle bubble, Stacked, etc... |

| MOQ | Unrestricted |

| Warranty | 3 years |

| After-sale Service | Online technical support |

| Size | Customized Size |

| Style | Modern |

| Occasion | Wall or Floor |

| Project Solution Capability | Total solution for projects |

| Application | Bathroom |

| Design Style | Modern |

| Place of Origin | China |

| Model Number | Brass Marble Waterjet Mosaic |

| Shape | Irregular |

1. Product Protection

Product protection includes three key aspects:

- Preventing damage to newly laid components: Avoid stepping on and polluting the tiles.

- Avoiding contamination: Cement mortar and adhesive materials should not come into contact with the surface or gaps of the travertine mosaic tile sheets.

- Preventing scratches: Sharp objects must be kept away to avoid damaging the particles.

2. Bottom Slurry Maintenance

The primer of travertine mosaic tile sheets requires a long curing period. This ensures sufficient time for the primer to release water vapor, meeting the requirements for the next construction process.

3. Overall Grouting Reinforcement Construction

The key focus of this stage is controlling the performance of the liquid glue and executing the grouting process in phases.

Glue Performance Control

Three factors play a crucial role in the effectiveness of liquid glue:

- Permeability: The thinner the glue, the stronger its ability to penetrate. The maximum dilution ratio of the original glue and the diluent is 1:1, ensuring sufficient permeability.

- Shrinkage: Thinner gel has greater shrinkage. The constructor must adjust the concentration based on specific needs to control shrinkage levels.

- Curing Time: A thinner glue has a longer curing time. To ensure proper penetration, it is ideal to start the curing process one hour after grouting. The grout concentration depends on the condition of the components and the effectiveness of penetration and cementation.

Staged Grouting Construction

Grouting should be done in phases based on penetration and reinforcement:

- First Grouting: Use a diluted slurry to ensure maximum permeability.

- Second Grouting: Apply liquid raw glue to reinforce the structure effectively.

Share