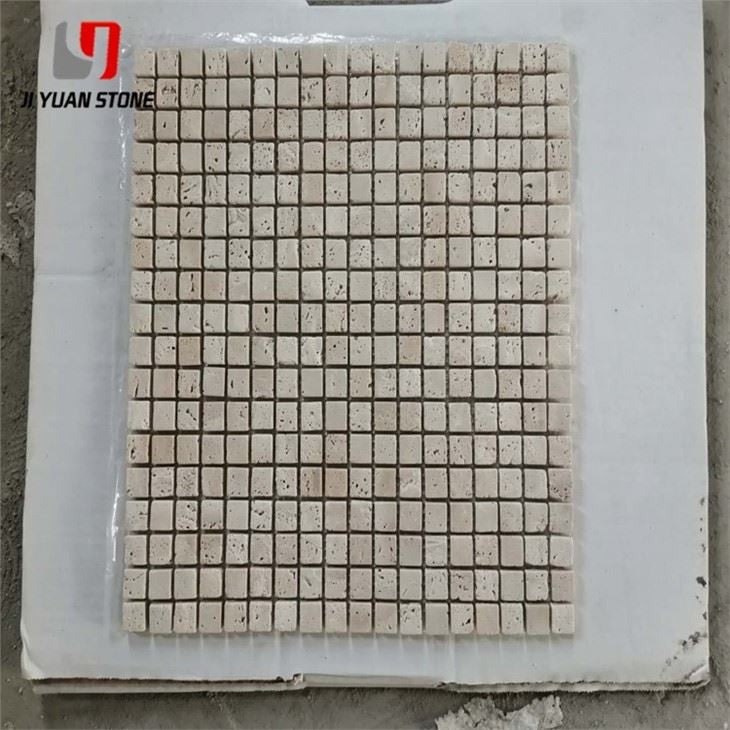

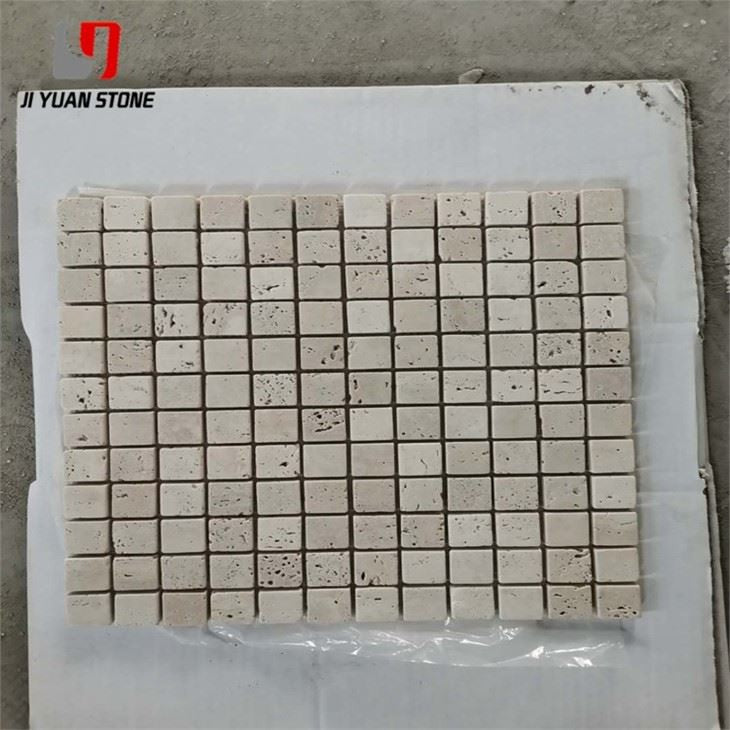

Travertine Mosaic Backsplash

Travertine Mosaic Backsplash

As a product of high-quality travertine, this mosaic backsplash is both durable and stylish. Its natural design adds a touch of elegance to any kitchen or bathroom space. The timeless material also provides excellent heat and moisture resistance, making it a practical and beautiful choice for any home.

| Feature | Details |

|---|---|

| Material | Natural Marble Stone,Travertine,Limestone |

| Colour | As pictures show or customized |

| Shape | Square, Basketweave, Mini brick, Modern brick, Herringbone, Subway, Hexagon, Octagon, Mixed, Grand fan, Penny round, Hand clipped, Tesserae, Random strip, River rocks, 3D cambered, Pinwheel, Rhomboid, Bubble round, Circle bubble, Stacked, etc... |

| MOQ | Unrestricted |

| Warranty | 3 years |

| After-sale Service | Online technical support |

| Size | Customized Size |

| Style | Modern |

| Occasion | Wall or Floor |

| Project Solution Capability | Total solution for projects |

| Application | Bathroom |

| Design Style | Modern |

| Place of Origin | China |

| Model Number | Brass Marble Waterjet Mosaic |

| Shape | Irregular |

1. Flatness Polishing Process

The flatness polishing process is an essential step in marble mosaic flooring due to inconsistencies in the thickness of travertine mosaic backsplashes, uneven particles after paving, and rubber accumulation from the grouting reinforcement. Without polishing, achieving a smooth and aesthetically pleasing finish would be difficult.

The polishing process for floor mosaics is more complex than standard surfaces and involves three key differences:

(1) Differences in Abrasives and Equipment

- The abrasives and construction equipment used for polishing should be carefully chosen to match the characteristics of the small, particle-shaped components.

- The cutting surface of the abrasive, along with the speed and weight of the equipment, must be controlled to prevent dislodging particles (since their thickness is only 0.5 cm).

(2) Differences in Grinding Depth

- The flatness requirement for a marble mosaic is 90%, with a grinding depth between 0.15 to 0.2 cm.

- Excessively low-lying particles should not be ground, as this could make components too thin or cause them to wear through.

(3) Differences in Corner Grinding

- Corner grinding is more labor-intensive and requires additional materials and grouting.

- The workload and process complexity are significantly higher than in large-scale construction.

This improved three-step process ensures reinforcement of the overall component before undertaking the final strong grinding process, leading to a smooth and visually appealing veneer.

2. Purchase of Materials

(1) Base-Layer Bonding Materials

- Besides cement, the base-layer bonding material should include a strong water-based adhesive as an interface agent.

- Additional materials may be required to enhance cement adhesion. Alternatively, pre-mixed adhesives that contain bonding agents can be used to improve adherence to the component's back net.

(2) Travertine Mosaic Backsplash Selection

- Since the mosaic requires flatness polishing, the thickest possible components should be selected.

- Particles should not be densely packed, and a wider gap between them is preferable for better results.

Share