1

/

of

9

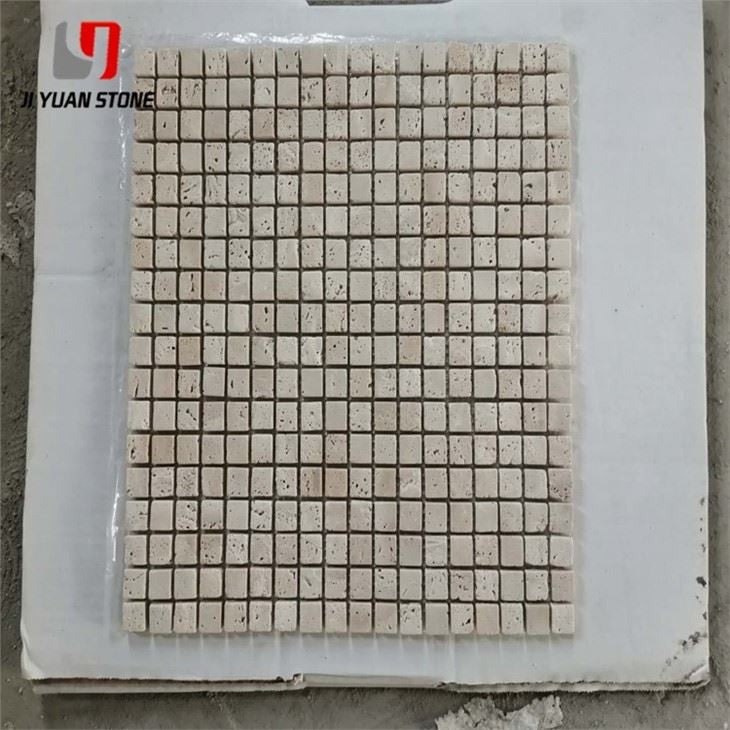

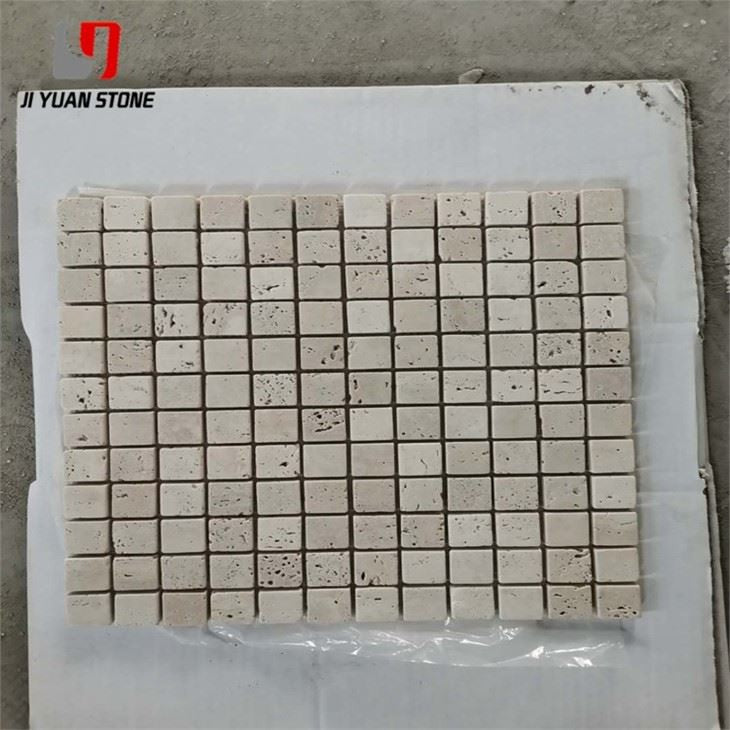

Travertine Marble Mosaic

Travertine Marble Mosaic

This Travertine Marble Mosaic is the perfect choice for adding a touch of elegance to any space. Made from natural travertine marble, it boasts durable and high-quality construction. Its unique and beautiful mosaic design will elevate the look of your home or office.

| Feature | Details |

|---|---|

| Material | Natural Marble Stone,Travertine,Limestone |

| Colour | As pictures show or customized |

| Shape | Square, Basketweave, Mini brick, Modern brick, Herringbone, Subway, Hexagon, Octagon, Mixed, Grand fan, Penny round, Hand clipped, Tesserae, Random strip, River rocks, 3D cambered, Pinwheel, Rhomboid, Bubble round, Circle bubble, Stacked, etc... |

| MOQ | Unrestricted |

| Warranty | 3 years |

| After-sale Service | Online technical support |

| Size | Customized Size |

| Style | Modern |

| Occasion | Wall or Floor |

| Project Solution Capability | Total solution for projects |

| Application | Bathroom |

| Design Style | Modern |

| Place of Origin | China |

| Model Number | Brass Marble Waterjet Mosaic |

| Shape | Irregular |

Specific Operation Process

1. Improvement of Paving Technology

The goal of improving the paving process is to enhance adhesion to the components. This involves several key steps:

- Using a glue-containing clear slurry: Ensure proper thickness of the base slurry so it fully bonds with the backing net while leaving enough margin for penetration into the particle gaps.

- Piercing through the back mesh: The primer should be forced into the closed particle gaps during paving and compacting to create a strong bond with the travertine marble mosaic.

- Applying an interface agent: The component back net should be coated with an interface agent to increase adhesion.

Important Considerations:

- Due to aesthetic requirements for seam color, primer overflow and bonding should be limited to the lower half of the mosaic particles.

- Increasing adhesion while controlling the amount of primer is crucial to achieving a stable and visually appealing finish.

2. Integral Grouting Reinforcement

Integral grouting reinforcement involves infiltrating and bonding all component gaps and bottom grout, creating a solid structure that unites:

- Travertine marble mosaic particles with each other.

- Mosaic particles with the primer.

There are two main types of grouting materials:

(1) Cement-Based Clear Mortar

- Contains coarse particles and has large bleeding pores, making it unable to infiltrate and strengthen fine gaps effectively.

(2) Liquid Glue (Recommended)

- Solvent: An oily thinner with strong permeability.

- Solute: An epoxy-based glue with high bonding strength.

-

Advantages:

- Thin, highly fluid, and penetrates deep into cement base slurry pores.

- Can be diluted and color-matched based on requirements.

- After curing and polishing, the surface becomes smooth, glossy, and resistant to contamination.

Limitations of Liquid Glue:

- Dilution ratio, curing time, and shrinkage must be carefully tested and controlled.

- Multiple grouting methods should be used for effective application.

- When purchasing materials, ensure that transparent, non-yellowing liquid glue and matching thinners are used.

Share