Travertine Limestone

Travertine Limestone

Travertine Limestone – A Natural Choice for Strength and Style

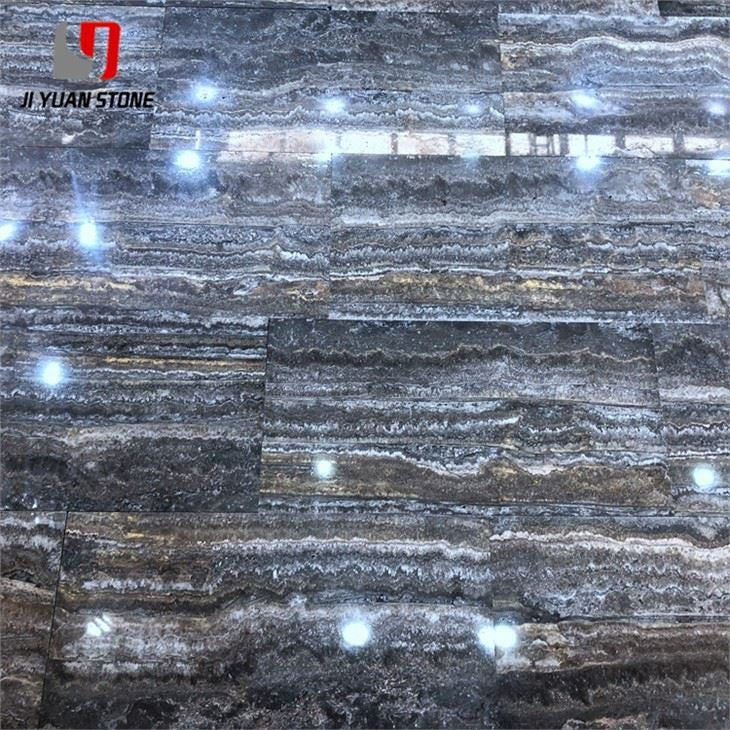

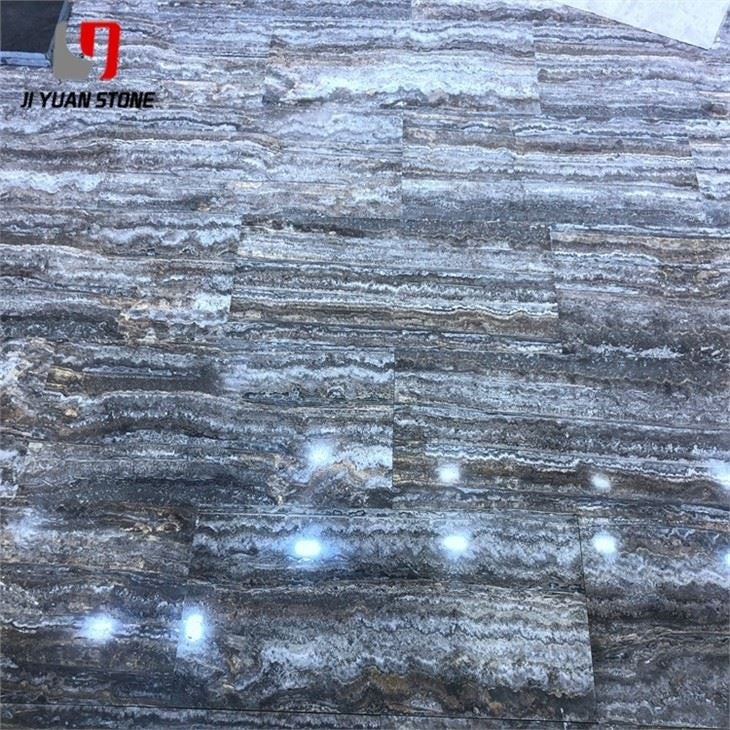

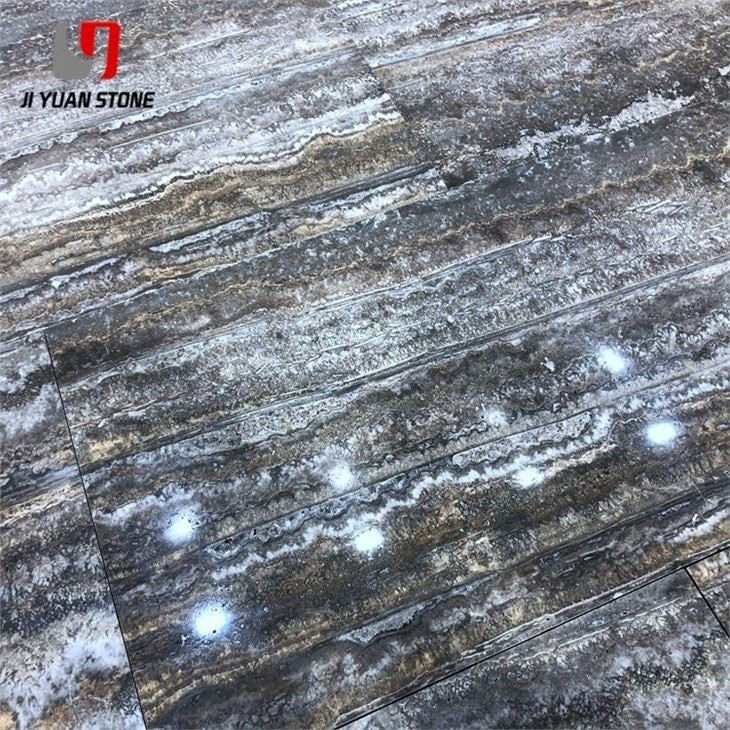

Travertine Limestone is a natural stone that offers timeless elegance and durability. With its unique veining and natural color variations, this stone adds a touch of sophistication to any indoor or outdoor space. Its low porosity and high density make it resistant to staining and temperature changes, making it the perfect choice for long-lasting beauty.

| Feature | Details |

|---|---|

| Material | Natural travertine |

| Colour | Silver, Grey |

| Thickness | 15mm , 16mm , 18mm , 20mm or customized |

| Slab sizes |

|

| Tile sizes | 300x300mm ; 600x600mm; 450x450mm etc |

| Surface | Polished |

| Edge processing | Machine cutting, round edge etc |

| Packing | Seaworthy wooden crate, pallet |

Travertine limestone is a timeless natural stone known for its soft textures, warm colors, and structural reliability. Ideal for both interior and exterior applications, this stone is widely used for flooring, wall cladding, stone furniture, architectural features, and custom stone crafts. Its natural beauty, combined with its strength, makes it a favorite for modern and classical construction alike.

🔧 Key Points of Travertine Limestone Bonding Method

Proper bonding is critical to maintain the aesthetic appeal and structural integrity of travertine limestone installations. Below are expert bonding techniques to ensure secure and durable results:

1. Surface Preparation

- Clean fractured or cut surfaces thoroughly to remove dust and debris.

- Ensure complete dryness of the bonding area—avoid any moisture.

- Use a high-pressure air pump to blow away particles for optimal adhesion.

- Eliminate any unstable or loose sections before gluing.

2. Adhesive Application

- Apply adhesive evenly and moderately to avoid gaps or weak bonding.

- Immediately align fractured pieces and squeeze them tightly.

- Allow for slight adhesive overflow to reinforce the bond.

- Clean the surface before gluing to prevent adhesive failure.

3. Bonding by Slab Thickness

Thick slabs (≥2cm):

- Use vertical bonding to allow natural weight to enhance grip.

- Use supports if needed and gently tap with a rubber or wooden mallet for precision.

Thin slabs (1cm):

- Use flat bonding on a level platform.

- Apply adhesive, squeeze together, and allow adequate hardening before handling.

4. Application-Specific Bonding Techniques

- Stone crafts, detailed designs, and shaped pieces: Use standard bonding steps.

- Arc panels: Vertical bonding ensures better coverage and grip.

- Intricate work like flower lines: Opt for flat bonding for better control and alignment.

5. Parquet Travertine Limestone Bonding

- Lay flat with oil paper underneath to avoid sticking.

- Use glass fiber net as a foundation for added strength.

- Align pieces accurately using a square or leaning ruler.

- Reinforce strength by applying a second adhesive layer on the back of dried parquet pieces.

6. Reinforcement Process for Cracked Stones

- For slabs with multiple cracks or natural faults, reinforce with glass fiber mesh backing.

- This is typically applied post-polishing and is now standard in many production lines to improve durability.

🏗️ Why Choose Travertine Limestone?

- Elegant natural appearance with soft beige, cream, and tan tones

- Versatile use: floors, walls, facades, furniture, and monuments

- Ideal for both residential and commercial applications

- Easy to cut, shape, and bond with professional-grade adhesives

- Reinforcement options available for cracked or fragile slabs

Whether you're working on large-scale construction, custom stone furniture, or intricate mosaic applications, travertine limestone offers unmatched versatility, natural beauty, and structural integrity.

🛒 Order now for competitive prices, custom sizes, and reliable international shipping from a trusted supplier.

Share