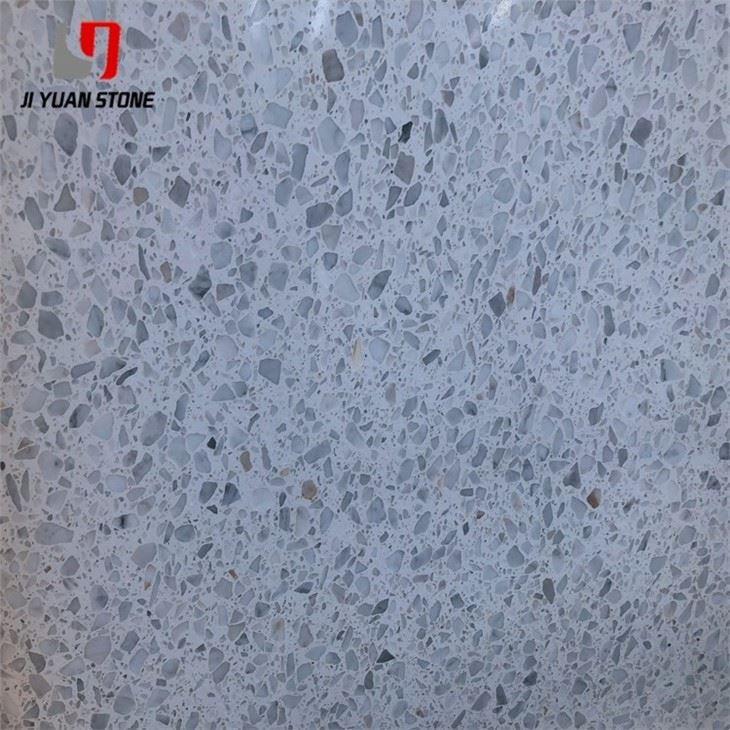

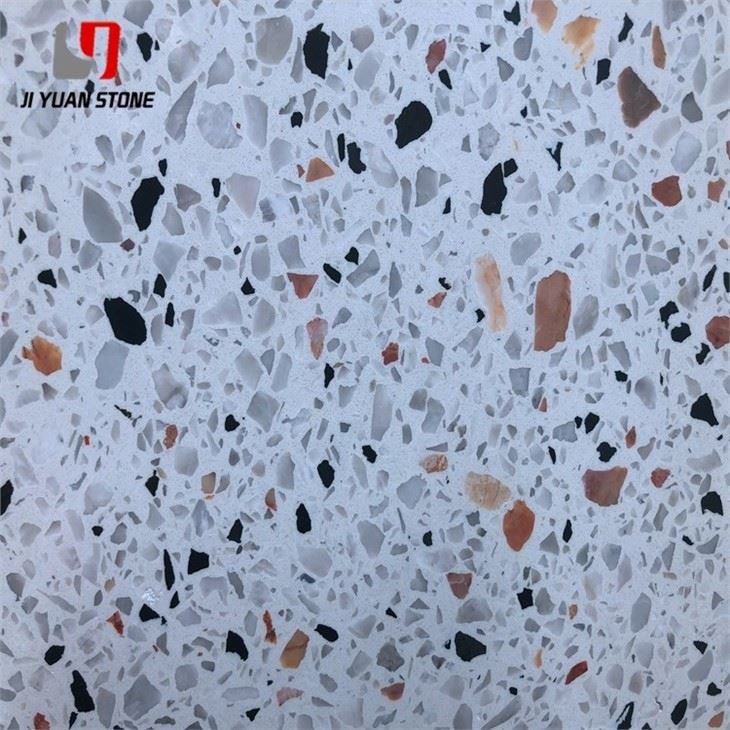

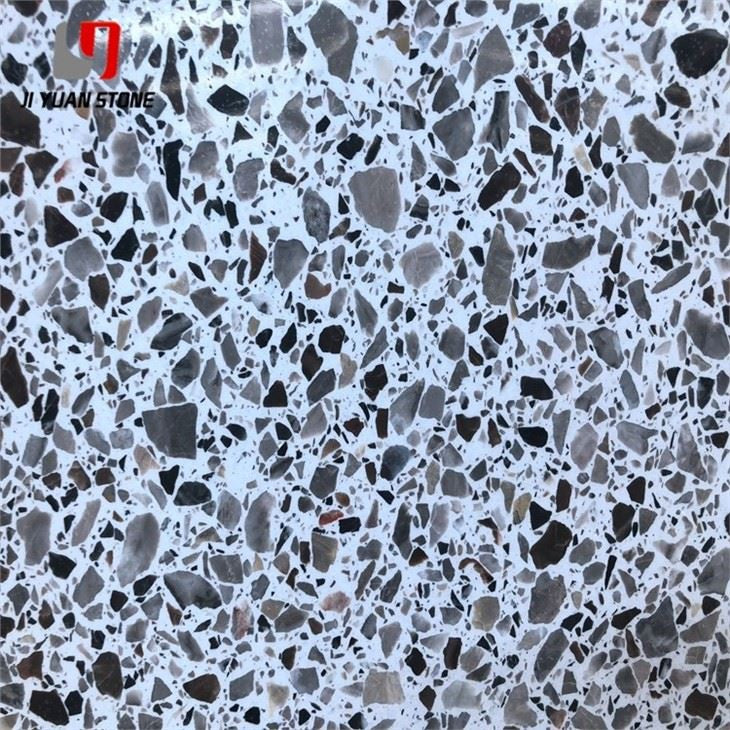

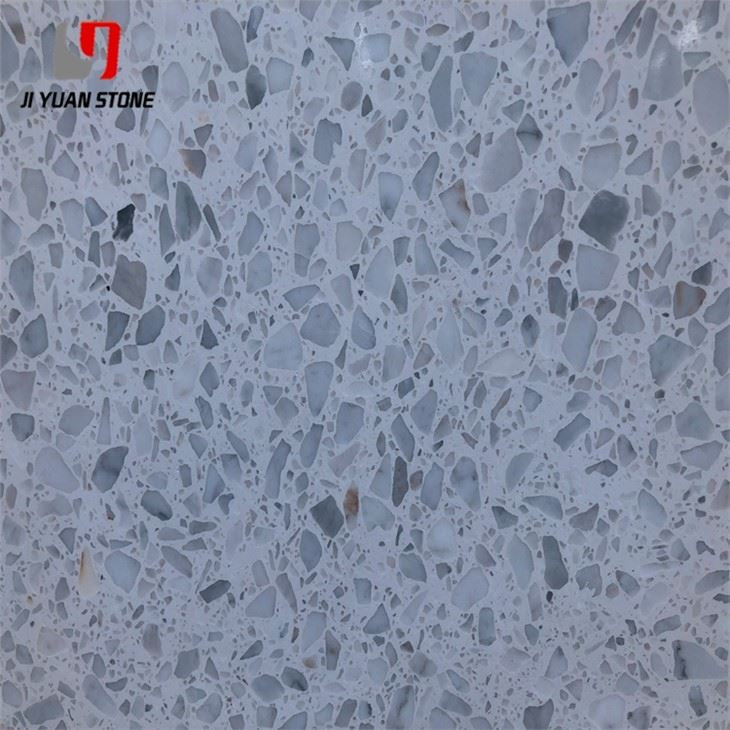

Terrazzo White Quartz

Terrazzo White Quartz

Terrazzo White Quartz – Elegant, Durable & Professional Installation Guide | Purchase Stones

Expertly crafted for a sleek and modern look, our Terrazzo White Quartz is a durable and low maintenance option for your space. With its unique blend of quartz and resin, this product boasts impressive strength and resistance to both heat and chemicals. Elevate your design with Terrazzo White Quartz.

| Feature | Details |

|---|---|

| Material | Terrazzo |

| Surface Finish | Polished,Honed |

| Common Slabs sizes |

|

| Common Tile sizes |

|

| Countertops Size |

|

| Vanity Tops Size |

|

| Edge Style | Bull nose, ogee, bevel, eased, polish, etc |

Transform your space with the timeless beauty and unmatched durability of Terrazzo White Quartz from Purchase Stones. This premium surface combines the elegance of natural stone with the resilience of engineered quartz, making it ideal for walls, floors, columns, and high-traffic areas. Its crisp white background with delicate aggregates offers a sophisticated look that complements both modern and traditional designs.

To ensure the finest results, follow our expert installation process designed for precision, stability, and long-lasting performance.

3.3.4 Elastic Thread – Ensuring Vertical Precision

- Begin by using large thread pendants to check verticality from top to bottom for marble, prefabricated terrazzo, or polished granite walls, cylinders, and window/door frames.

- For high-rise projects, a theodolite can be used for accuracy.

- Factor in slab thickness, mortar voids, and steel mesh size. Typically, the outer skin thickness from the structural surface is 5–7 cm.

- After establishing vertical alignment, mark the outline dimensions of the terrazzo white quartz slabs on the ground along the wall (or around the cylinder, similar to a window/door cover).

- For numbered slabs, mark the installation baseline and leave a 1 mm gap between each piece unless otherwise specified by the design.

3.3.5 Installing Terrazzo White Quartz Slabs

1 . Positioning & Securing:

- Select the slab for its designated position.

- Straighten the copper wire or galvanized lead wire, place the slab, and reach behind it to tie the wire to the crossbar. Leave a little slack—final anchoring occurs after grouting.

- Stabilize the slab with wooden wedges.

2 . Gap Management:

- Maintain a 30–50 mm gap between the slab and the base layer for grouting.

- Use a ruler to check alignment and adjust as needed before fastening wires.

3 . Installation Direction:

- For cylinders, install slabs in a clockwise direction, typically starting from the front.

- Use a level, square, and ruler to ensure perfect vertical, horizontal, and angular alignment.

4 . Uniform Spacing:

- If slabs vary in size or spacing, use lead sheeting to cushion and align them so all gaps remain even.

- Ensure the opening line of the first layer remains straight.

5 . Plaster Bonding:

- Once aligned, prepare plaster of paris to a porridge-like consistency and apply between upper and lower slabs to unify layers.

- Wooden wedges can also be secured with plaster.

- After the plaster hardens, check for deformation, then proceed with grouting (if using a caulking hose, insert it before grouting).

Why Choose Terrazzo White Quartz from Purchase Stones?

- Elegant Appearance: Crisp white tones with subtle aggregates for a refined, luxurious look.

- Exceptional Durability: Resistant to wear, stains, and moisture.

- Versatile Applications: Suitable for interior and exterior wall cladding, columns, and decorative surfaces.

- Professional Installation Guidance: Detailed methods for flawless results.

Care Tip:

For outdoor summer installations, protect slabs from direct sunlight to prevent rapid setting or surface damage.

Order Terrazzo White Quartz from Purchase Stones today and combine world-class craftsmanship with professional-grade installation for a space that stands the test of time.

Share