Terrazzo Vanity

Terrazzo Vanity

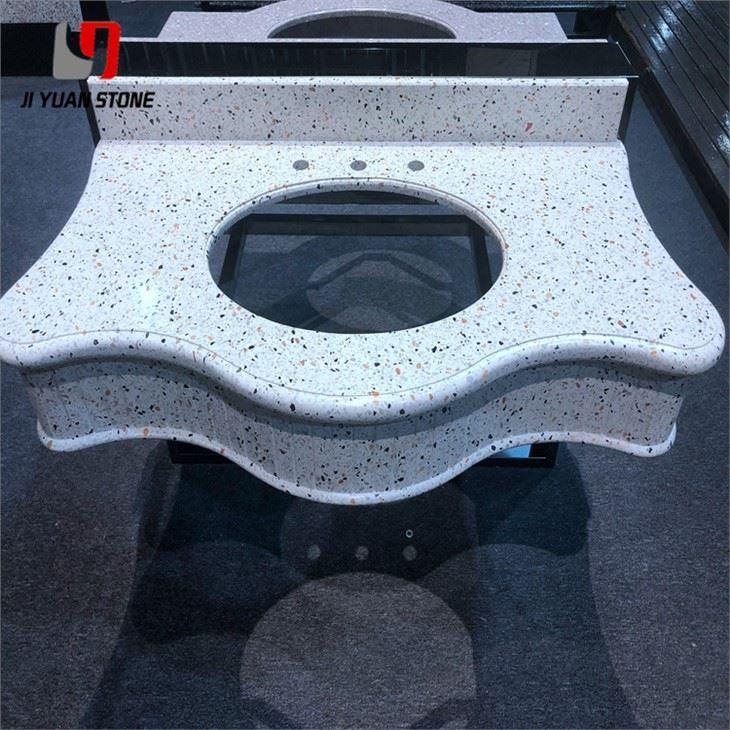

Terrazzo Vanity – Durable, Elegant & Timeless

This Terrazzo Vanity combines stunning design with durable construction. Made from high-quality terrazzo material, this vanity will add a touch of elegance to any bathroom. Its unique texture and pattern make it a beautiful focal point, while its sturdy build ensures long-lasting use. A must-have for any bathroom renovation.

| Feature | Details |

|---|---|

| Material: | Terrazzo |

| Surface Finish: | Polished,Honed |

| Terrazzo Water Aborption: | 1-3% |

| Surface Finish: | Matt, No Polished |

| Main Size: | 600*600mm |

| Customized Size: | 300*600mm, 600*600mm, 400*800mm, 800*800mm, 600*1200mm |

| Body Technology: | 50% Good Quality Body |

| Glazed Technology: | 3D HD Print |

| Customized Body: | Color Full Body, Fabric Full Body |

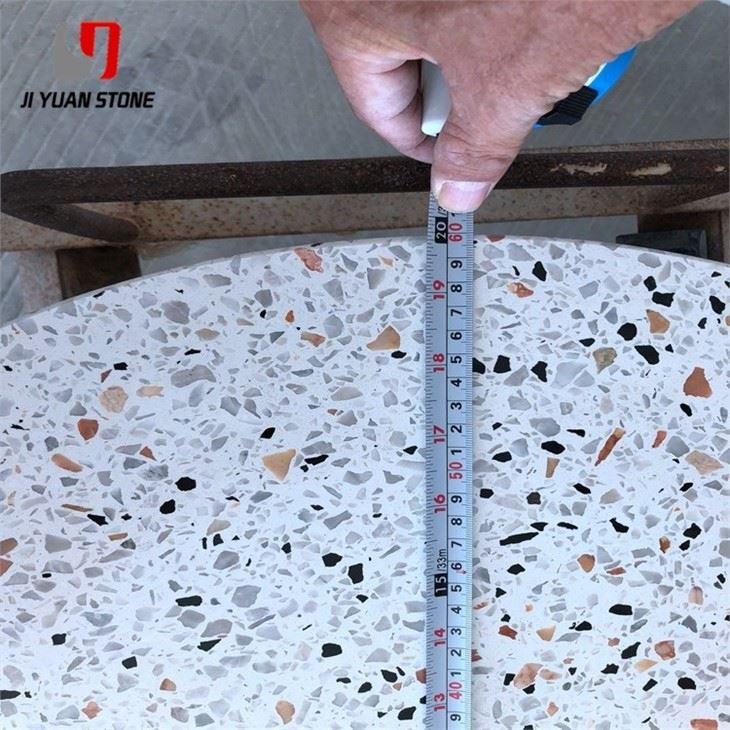

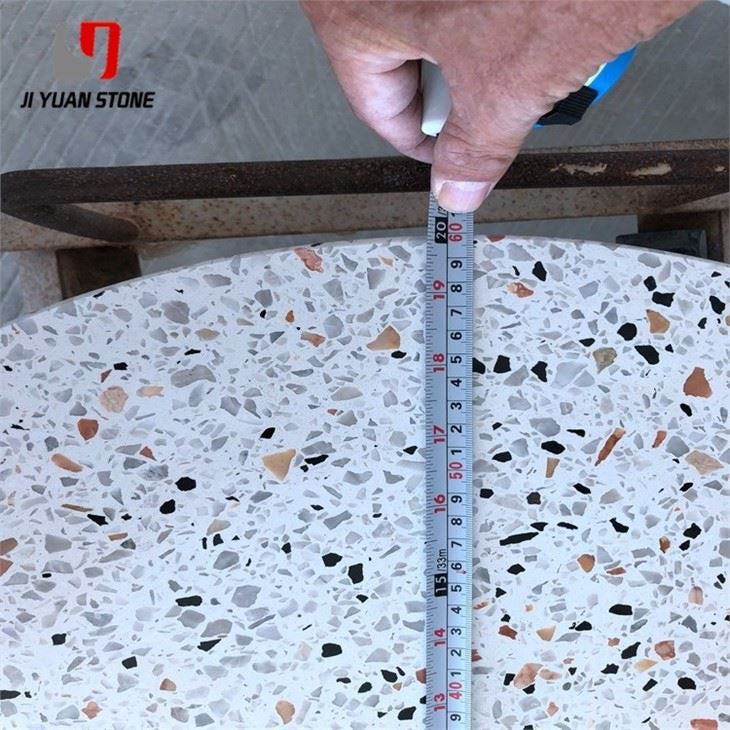

| Thickness: | 9.3+/-0.3MM (Thickness according to the size) |

| Usage: | Wall and Floor Tiles for Living room,bathroom,coffee shop |

| Sample: | Contact us for free sample |

| Sample ETD: | 7-10 Days After Detail Confirmed |

| Function: | Wear-resistant, Non-slip, Acid-resistant, Low water-absorption |

A terrazzo vanity is a versatile and stylish surface, created by mixing marble, granite, quartz, and other aggregates into cement, then grinding and polishing the surface to perfection. Depending on the bonding material, terrazzo can be classified into:

- Inorganic Grindstone (Cement Terrazzo) – Made using cement as a binder.

- Epoxy or Organic Grindstone – Made using epoxy resin as a binder.

According to the construction process, terrazzo is also divided into on-site pouring terrazzo and prefabricated terrazzo panels.

Terrazzo in Modern Design

As a type of artificial stone, terrazzo is no longer confined to architectural projects—it’s now a sought-after material in interior design. Popular choices include:

- Artificial stone terrazzo

- Inorganic terrazzo

- Epoxy terrazzo vanity designs

On-Site Pouring Terrazzo

Cast-in-place terrazzo is more common in large-scale commercial projects in China but is rarely used in home interiors due to its complex installation process.

Advantages – Full control over colors and patterns; seamless, durable surface.

Process Requirements – Skilled craftsmanship, quality raw materials, mixer, and grinder.

Types:

- Traditional Cement Terrazzo Vanity – Affordable, simple construction, but more prone to wear and less visually refined than epoxy terrazzo.

- Epoxy Resin Terrazzo Vanity – Higher aesthetic appeal, vivid color reproduction, and less prone to cracking, but more expensive and less eco-friendly.

Terrazzo Vanity Construction Details

On-site terrazzo pouring process includes:

1 . Leveling Layer – Made of fine stone concrete or anti-cracking mortar, typically 40mm–50mm thick.

2 . Metal Divider Strips – Used for sectioning and creating patterns.

3 . Terrazzo Vanity Surface Layer – Varies by design, usually 5mm–10mm thick.

Why Choose a Terrazzo Vanity?

- Durability – Resistant to scratches and wear.

- Custom Design – Wide range of colors, patterns, and finishes.

- Stylish Appeal – Complements modern, retro, and minimalist interiors.

- Eco-Friendly Options – Cement terrazzo is more sustainable.

A terrazzo vanity offers the perfect blend of style, strength, and personalization—making it a statement piece in bathrooms, powder rooms, and commercial spaces alike. Whether you prefer the natural charm of cement terrazzo or the luxury finish of epoxy terrazzo, this timeless material adds texture, elegance, and value to any space.

If you’d like, I can also prepare SEO keyword clusters for this page so it ranks for phrases like “custom terrazzo vanity,” “epoxy terrazzo bathroom counter,” and “cement terrazzo sink top”. This will boost both visibility and conversion potential.

Share