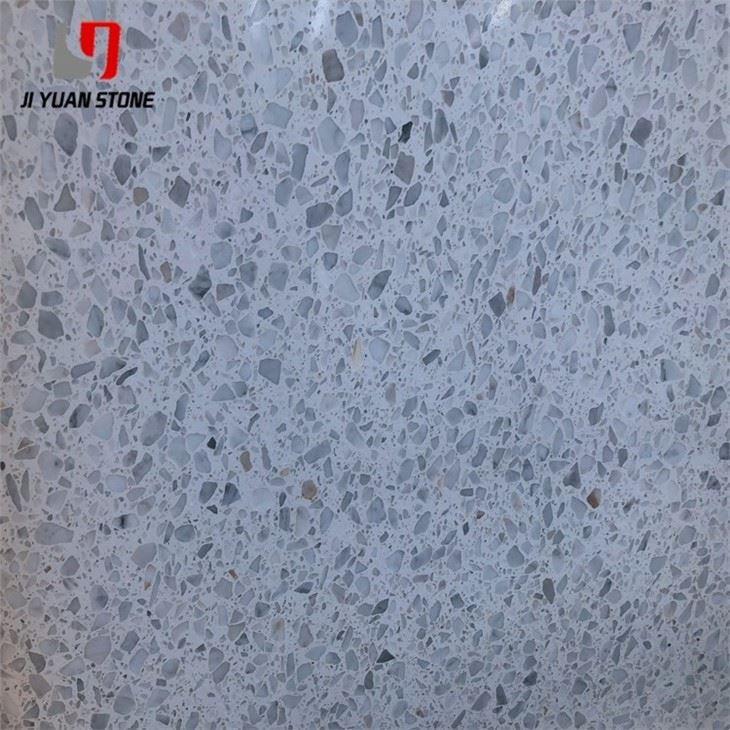

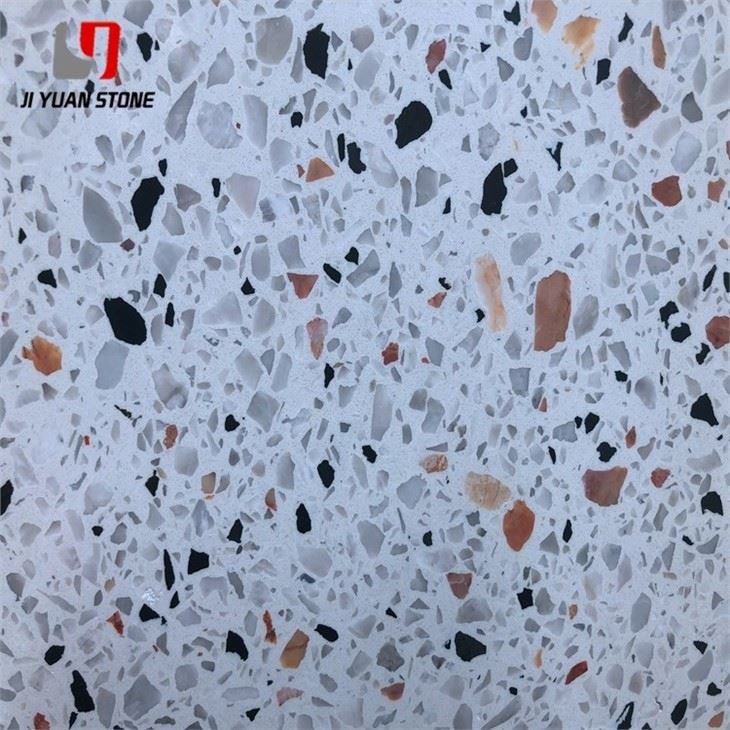

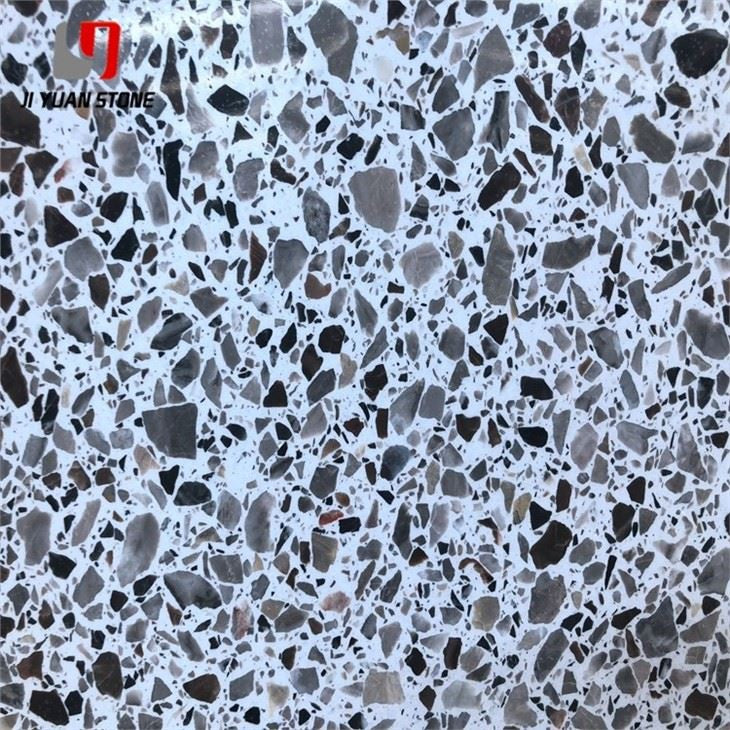

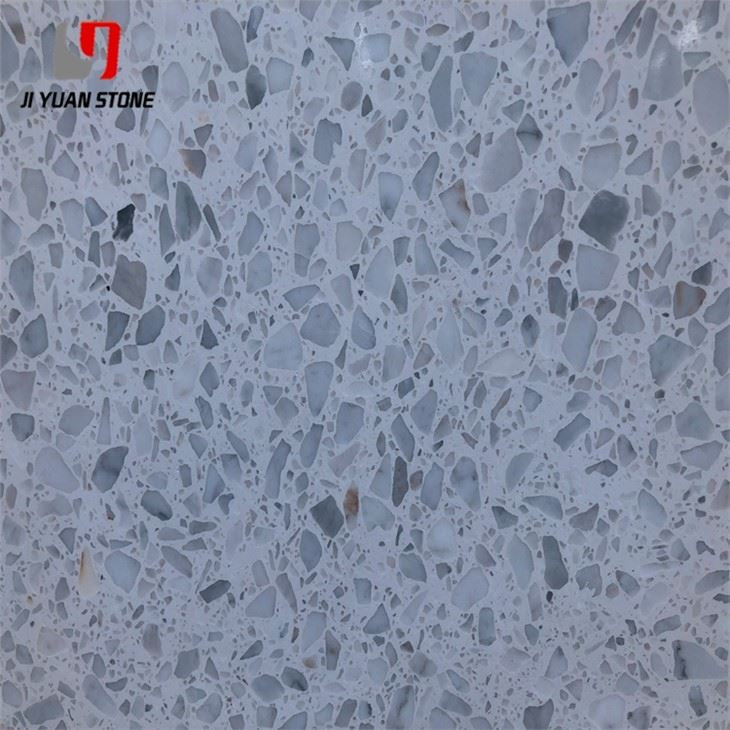

Terrazzo Stone White

Terrazzo Stone White

Terrazzo Stone White – Elegant, Durable & Easy to Install

Expertly crafted with the finest Terrazzo Stone, our Terrazzo Stone White offers a sleek and durable surface that adds a touch of elegance to any space. With its timeless appeal and easy maintenance, our Terrazzo Stone White is the perfect choice for your next renovation or construction project.

| Feature | Details |

|---|---|

| Material | Terrazzo |

| Surface Finish | Polished,Honed |

| Common Slabs sizes |

|

| Common Tile sizes |

|

| Countertops Size |

|

| Vanity Tops Size |

|

| Edge Style | Bull nose, ogee, bevel, eased, polish, etc |

Bring timeless elegance and strength to your space with our Terrazzo Stone White collection. Perfect for luxury interiors, commercial projects, and modern architectural designs, these tiles combine refined beauty with long-lasting durability. Whether used for walls, floors, or feature areas, terrazzo stone white adds a sleek, polished look while offering excellent resistance to wear and tear.

Our installation methods ensure a flawless and secure fit for any application, whether you are working with thin, small tiles or large-format slabs.

3.2 Thin and Small Size Block Material

(Generally thickness less than 10mm; side length less than 40mm) – The pasting method can be used for a smooth and secure finish.

3.2.1 Carry out basic treatment and vertical lifting, set squares, and find rules according to the construction points of veneer tiles. Ensure there is no more than one row of non-whole bricks on the same wall, and place them in more hidden parts for the best appearance.

3.2.2 When the base layer is wet, brush a line of 107 glue cement slurry (with 10% water weight 107 glue). Apply the bottom layer using 1:3 cement mortar with a thickness of about 12mm, divided into two passes—first 5mm, then 7mm. Compact and flatten the surface, then scratch it for better adhesion.

3.2.3 After the base ash is solidified, mark elastic lines to divide sections. Apply a 2–3mm thick plain cement slurry to the wet block material, adding 107 glue (20% water weight) or rubber powder for better bonding. Tap lightly with a wooden hammer and straighten with a ruler.

3.3 Large Size Blocks

(When side length exceeds 40mm and mounting height is over 1m) – Use the installation method for secure placement.

3.3.1 Drilling and Grooving: Before installation, drill veneer tiles like terrazzo stone white using a bench drill as per design requirements. Position the wooden frame to align the drill with the upper end of the board. Drill holes on the upper and lower sides of each slab, at 1/4 width from both ends. Use a 5mm diameter and 12mm depth, placing holes about 8mm from the back (center of the hole).

For larger plates such as prefabricated terrazzo or polished terrazzo stone white, increase the number of holes for extra stability. After drilling, use a steel chisel to lightly cut a 5mm deep groove on the back wall of the slab. Combined with the drilled hole, this forms an “elephant’s nose” shape for embedding the copper wire, ensuring a secure and lasting fit.

Why Choose Terrazzo Stone White?

- Premium Finish: Polished elegance that enhances any design style.

- Durability: Resistant to wear, stains, and environmental factors.

- Versatility: Suitable for residential, commercial, and public spaces.

- Expert Installation Techniques: Ensuring lasting stability and flawless beauty.

Transform your home or project with Terrazzo Stone White, where timeless style meets superior craftsmanship.

Share