Terrazzo Stone Tiles

Terrazzo Stone Tiles

Premium Terrazzo Stone Tiles – Durable, Stylish & Easy to Install

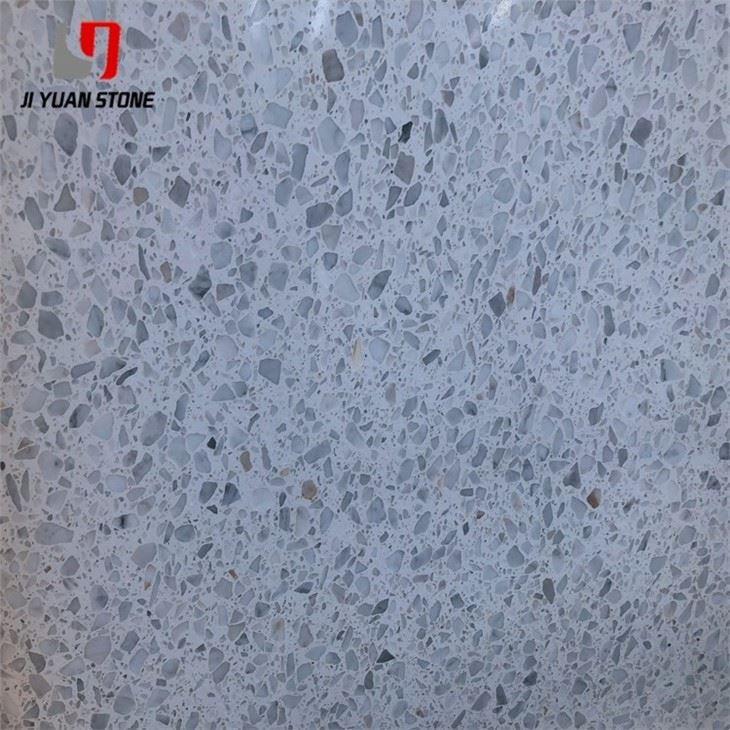

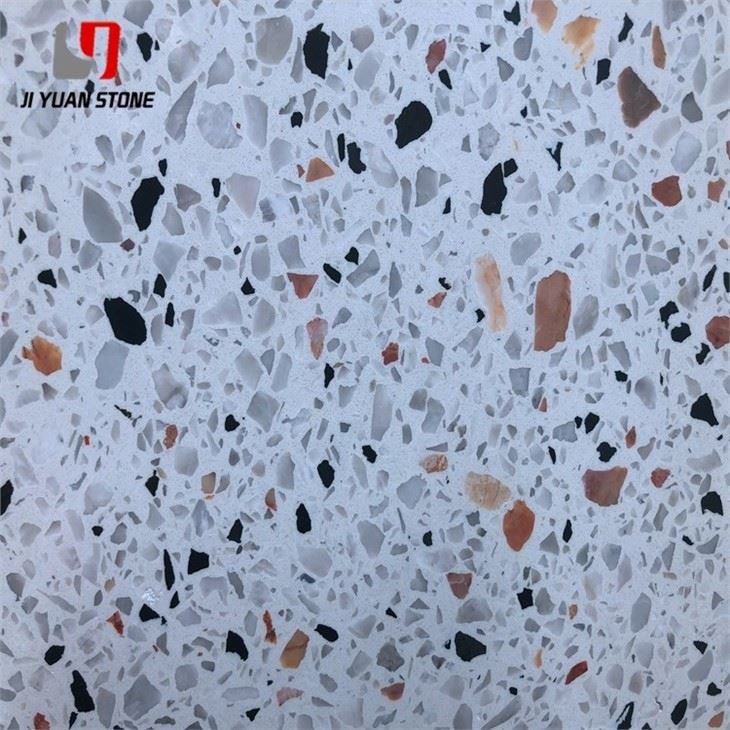

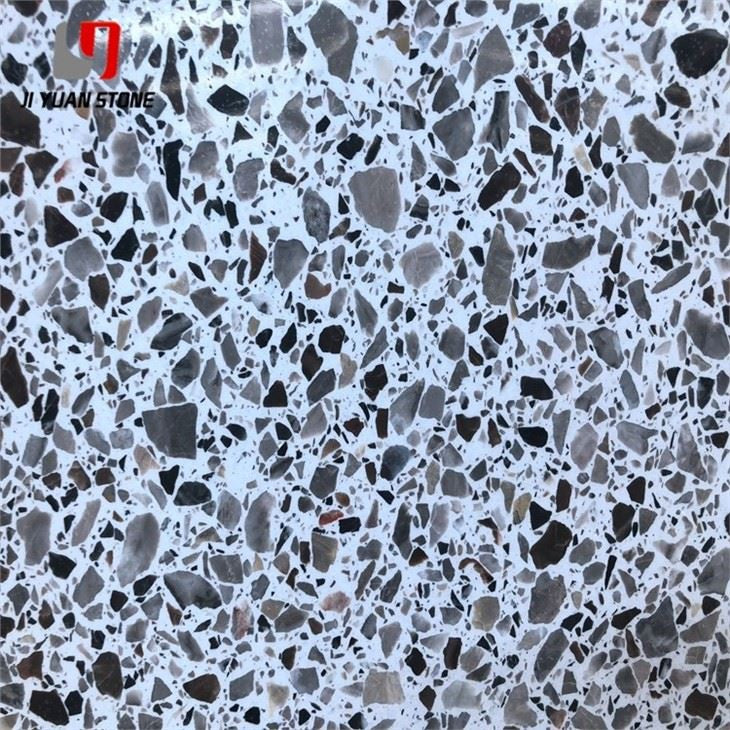

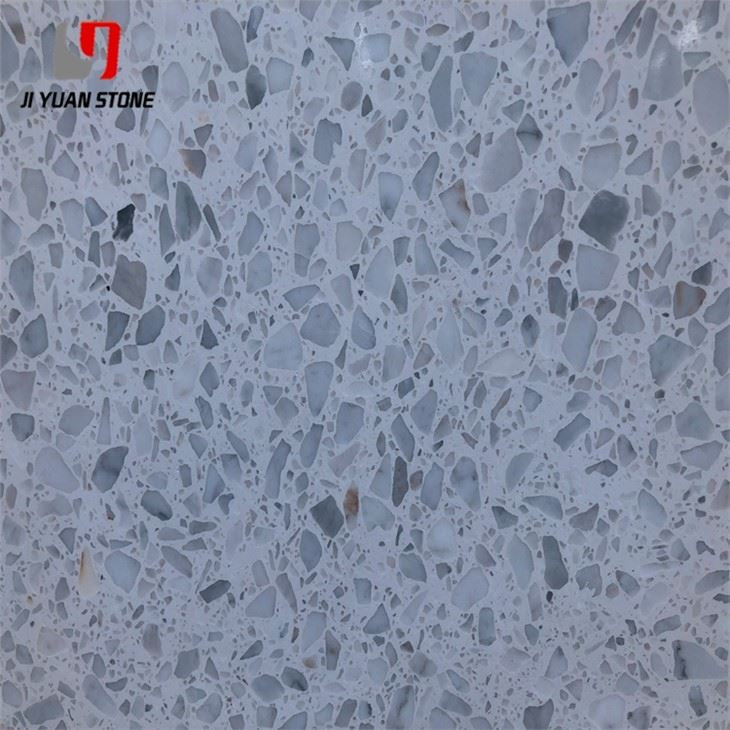

Introducing our Terrazzo Stone Tiles - perfect for both indoor and outdoor use. Made from high-quality materials, these durable tiles are resistant to scratches, stains, and moisture. Add a touch of elegance to your space with the unique and timeless design of Terrazzo. Suitable for all types of spaces, these tiles are a must-have for any interior design project.

| Feature | Details |

|---|---|

| Material | Terrazzo |

| Surface Finish | Polished,Honed |

| Common Slabs sizes |

|

| Common Tile sizes |

|

| Countertops Size |

|

| Vanity Tops Size |

|

| Edge Style | Bull nose, ogee, bevel, eased, polish, etc |

Enhance your interiors and exteriors with our premium Terrazzo Stone Tiles, known for their timeless appeal, exceptional durability, and elegant finish. Perfect for both residential and commercial spaces, these tiles combine classic charm with modern resilience, making them ideal for high-traffic areas, luxury flooring, wall cladding, and outdoor applications.

If the veneer size is large, especially the prefabricated terrazzo and polished terrazzo stone tiles, when the lower end is not easy to control and tie the galvanized lead wire or copper wire, you can also use a portable light and small grinding wheel on the side of the veneer that is not inlaid (4–5mm). According to the regulations, cut a slot on the top and bottom of the 1/4 of the board height (slot length about 3–4mm, groove depth about 12mm) and open the back of the decorative panel. The vertical slot is generally in the middle but can also be outside, taking care not to damage the exterior surface or reverse the alkali. The galvanized lead wire or copper wire can be placed in the groove, then tied and fixed with the steel mesh. This method can also be done directly at the mounting site, ensuring secure and professional installation of terrazzo stone tiles.

Terrazzo Stone Tiles Operation Technology

Wearing steel wire or galvanized lead wire: Cut the prepared copper wire or galvanized lead wire to a length of about 20cm, and use a wooden wedge to glue epoxy resin into the hole to fix the wire firmly. Bend the copper wire or galvanized lead wire along the hole so it lies in the slot, ensuring no protrusions at the lower end. This keeps the seam tight with the adjacent slate, enhancing aesthetics and strength.

Lashing steel mesh: First, remove embedded ribs on the wall and clean the section where marble, prefabricated terrazzo, or polished terrazzo stone tiles will be installed. Bind a vertical φ6 steel bar, bending it to connect with the embedded bar. For example, when the slab height is 60cm, tie the first horizontal bar 10cm above the ground to secure the lower edge of the first tile layer. The second horizontal bar is tied 7–8cm below the top edge of the tile, ensuring strong anchoring. Continue tying a crossbar every 60cm upward for consistent reinforcement.

Our terrazzo stone tiles are crafted for long-lasting performance, easy maintenance, and versatile design possibilities. Whether you are upgrading a luxurious indoor floor or creating a stunning outdoor pathway, these tiles bring elegance, strength, and unmatched quality to your space.

Share