Terrazzo Round Dining Table

Terrazzo Round Dining Table

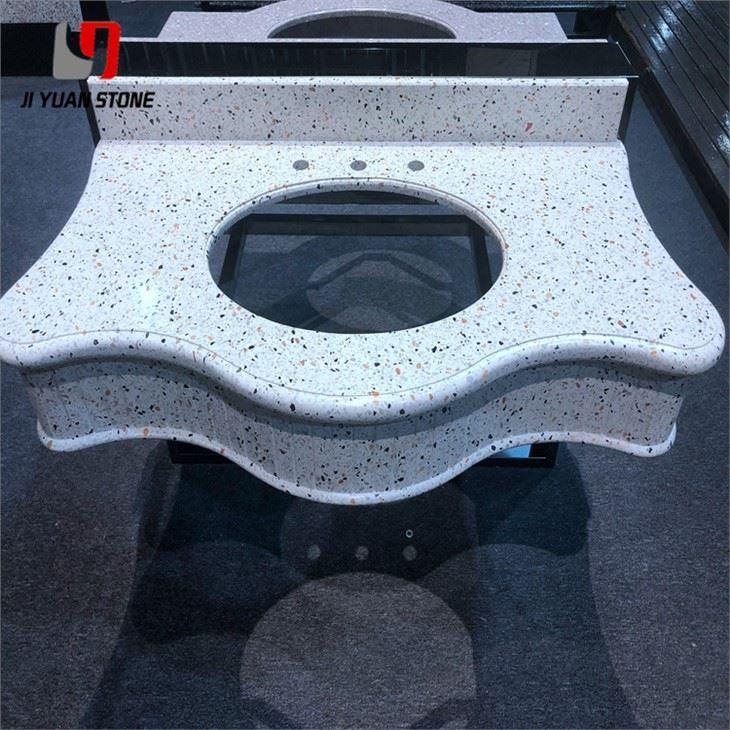

Terrazzo Round Dining Table – Durable Elegance for Modern Spaces

Discover the perfect blend of modern design and durability with our Terrazzo Round Dining Table. Crafted from high-quality terrazzo, this circular table brings a sleek and stylish touch to any dining space. Its unique texture and sturdy construction make it a long-lasting addition to your home.

| Feature | Details |

|---|---|

| Material: | Terrazzo |

| Surface Finish: | Polished,Honed |

| Terrazzo Water Aborption: | 1-3% |

| Surface Finish: | Matt, No Polished |

| Main Size: | 600*600mm |

| Customized Size: | 300*600mm, 600*600mm, 400*800mm, 800*800mm, 600*1200mm |

| Body Technology: | 50% Good Quality Body |

| Glazed Technology: | 3D HD Print |

| Customized Body: | Color Full Body, Fabric Full Body |

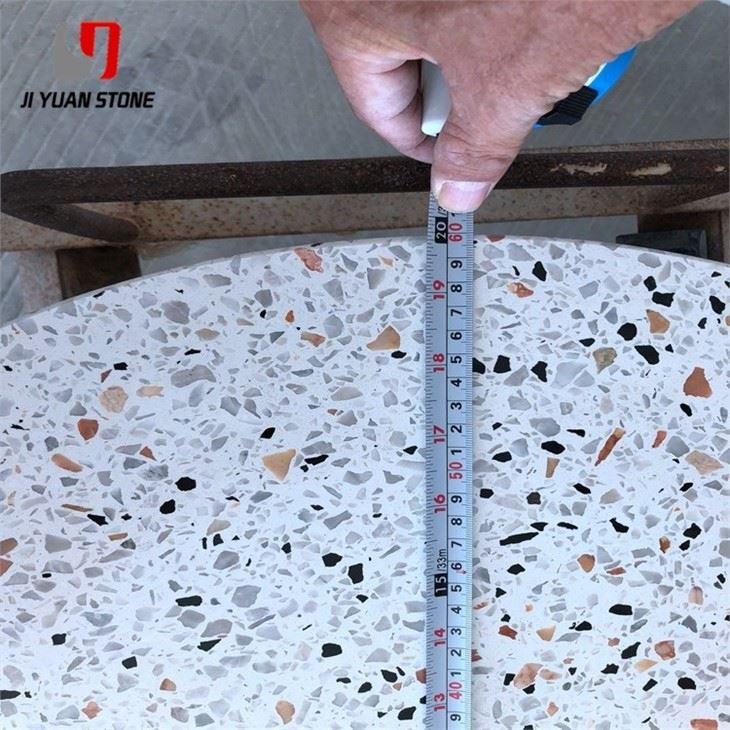

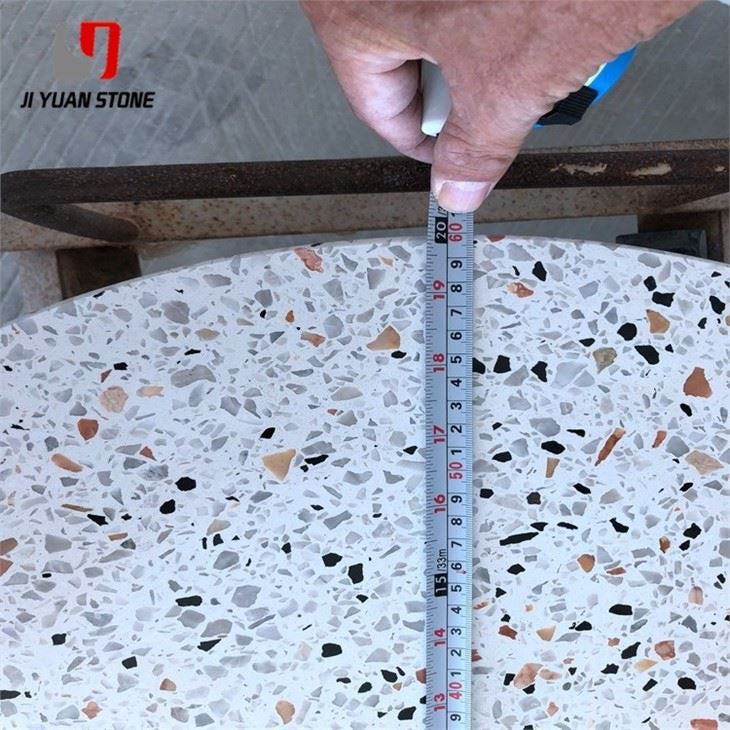

| Thickness: | 9.3+/-0.3MM (Thickness according to the size) |

| Usage: | Wall and Floor Tiles for Living room,bathroom,coffee shop |

| Sample: | Contact us for free sample |

| Sample ETD: | 7-10 Days After Detail Confirmed |

| Function: | Wear-resistant, Non-slip, Acid-resistant, Low water-absorption |

Types of Terrazzo and Their Applications

Terrazzo is a timeless, versatile material used across a wide range of settings—from industrial floors to high-end commercial interiors. Depending on construction methods and intended use, terrazzo can be categorized into cast-in-place and prefabricated types, with further divisions based on industrial, civil, and commercial applications.

1. Cast-in-Place Terrazzo

Cast-in-place terrazzo is most often used in large-scale commercial projects in China but is less common in home interiors.

A distinctive feature of cast-in-place terrazzo floors and round dining tables is the use of copper strips, which serve two purposes:

- Aesthetic enhancement by creating decorative patterns.

- Structural integrity by reducing the likelihood of cracking—a common terrazzo issue.

This method allows for high customization and seamless finishes, making it ideal for statement dining tables in restaurants, hotels, and luxury residences.

2. Prefabricated Terrazzo

Prefabricated terrazzo is factory-produced using specialized machinery and then installed on-site.

Advantages:

✅ Higher surface gloss than cast-in-place terrazzo.

Disadvantages:

❌ Less customizable in terms of patterns and colors.

❌ Requires cement joints during installation, which may darken over time and trap dirt or odors.

Prefabricated terrazzo round dining tables can be tailored for industrial, civil, or commercial use depending on the setting.

3. Types of Terrazzo Based on Application

(1) Industrial Terrazzo

- Used in factories, warehouses, and parking lots.

- Made from granite grains and ordinary Portland cement.

- Highly durable and cost-effective, though less decorative.

(2) Civil Terrazzo

- Found in villas, hospitals, public squares, and subway stations.

- Aesthetic appeal enhanced with green/red marble particles and high-grade white or colored cement.

- Comparable in price to polished brick flooring but offers a more refined finish.

(3) Commercial Terrazzo

- Common in shopping malls, office towers, and luxury retail stores.

- Requires a polished, high-gloss finish that is dust-free, wear-resistant, and easy to clean.

- Achieves a marble-like look at one-third the cost of real marble.

Why Choose a Terrazzo Round Dining Table?

A terrazzo round dining table combines durability, design flexibility, and timeless style. Whether opting for cast-in-place for a custom luxury piece or prefabricated for efficient installation, terrazzo delivers exceptional beauty and long-lasting performance.

Perfect for modern homes, upscale restaurants, and premium commercial spaces, terrazzo’s ability to mimic marble at a fraction of the cost makes it a smart and stylish choice for today’s interiors.

If you’d like, I can also prepare an LSI keyword-rich variation so this product page ranks not just for “terrazzo dining table” but also “round terrazzo table,” “modern terrazzo dining furniture,” and “marble-look terrazzo table.” That will help this page compete in broader search results.

Share