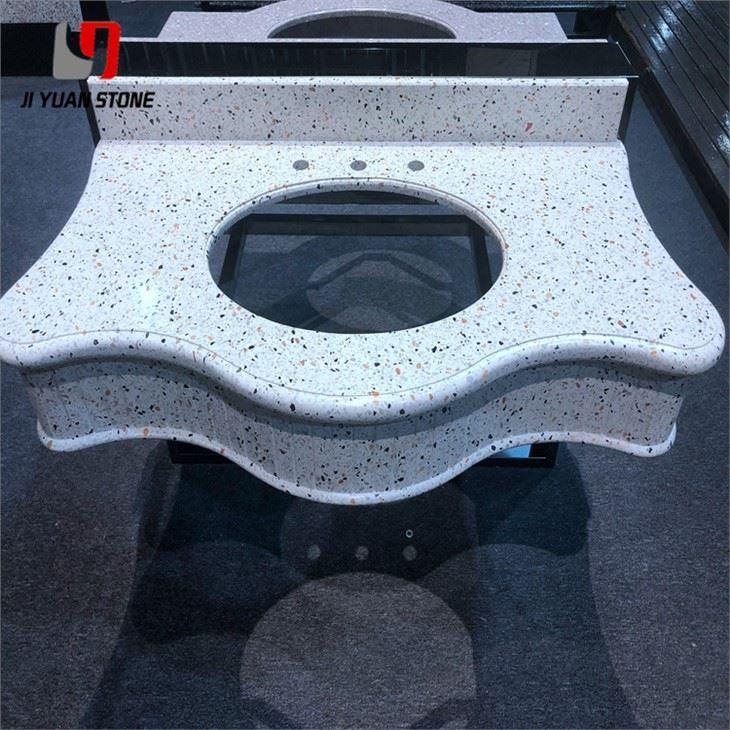

Terrazzo Round Coffee Table

Terrazzo Round Coffee Table

Terrazzo Round Coffee Table – Durable, Elegant & Versatile

Expertly crafted with a modern design, our Terrazzo Round Coffee Table adds a touch of sophistication to any living space. Made with durable materials, this coffee table is built to last while providing a stylish and functional addition to your home. Elevate the look of your living room with this timeless piece.

| Feature | Details |

|---|---|

| Material: | Terrazzo |

| Surface Finish: | Polished,Honed |

| Terrazzo Water Aborption: | 1-3% |

| Surface Finish: | Matt, No Polished |

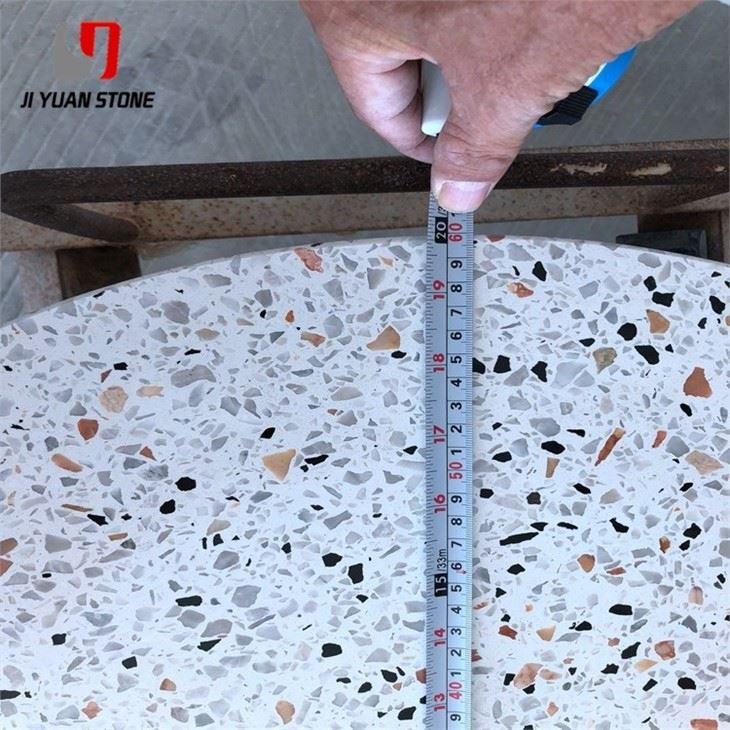

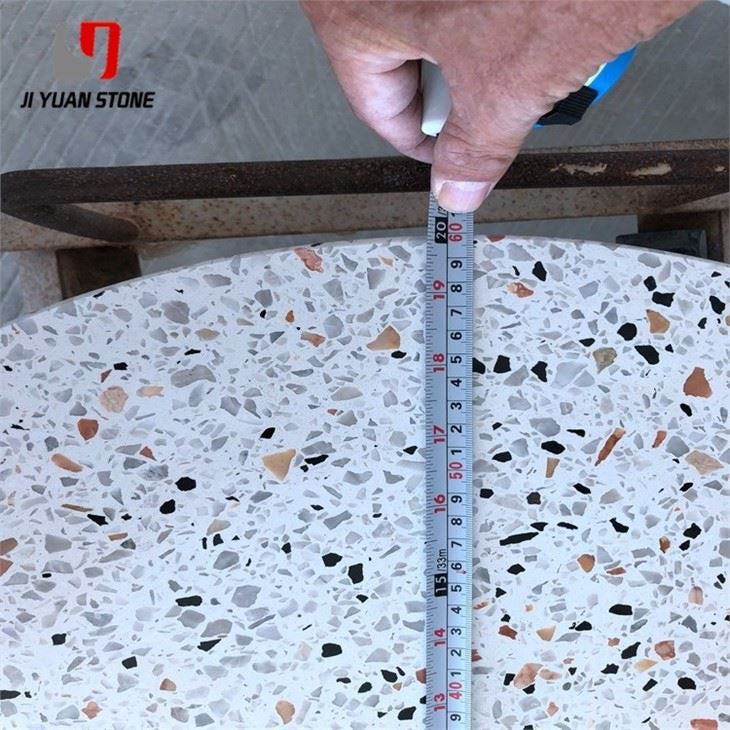

| Main Size: | 600*600mm |

| Customized Size: | 300*600mm, 600*600mm, 400*800mm, 800*800mm, 600*1200mm |

| Body Technology: | 50% Good Quality Body |

| Glazed Technology: | 3D HD Print |

| Customized Body: | Color Full Body, Fabric Full Body |

| Thickness: | 9.3+/-0.3MM (Thickness according to the size) |

| Usage: | Wall and Floor Tiles for Living room,bathroom,coffee shop |

| Sample: | Contact us for free sample |

| Sample ETD: | 7-10 Days After Detail Confirmed |

| Function: | Wear-resistant, Non-slip, Acid-resistant, Low water-absorption |

Terrazzo Construction Techniques and Maintenance

Terrazzo is a timeless, versatile material widely used in coffee tables, flooring, and wall applications. It is available in two main construction methods—cast-in-place and prefabricated terrazzo—each offering unique benefits for style, durability, and design flexibility.

1. Cast-in-Place Terrazzo Round Coffee Table

The cast-in-place method involves pouring terrazzo on-site, ensuring a seamless, custom-fitted finish. There are two primary types:

- Traditional Cement Terrazzo – Affordable with simple construction, but more prone to wear and offers limited visual variety.

- Epoxy Terrazzo – Sleek, wear-resistant, and refined in appearance, though more expensive and less eco-friendly than cement terrazzo.

Traditional Production Process:

1 . Base preparation → Elevation setting → Horizontal line marking

2 . Spreading screed mortar → Curing → Grid line marking

3 . Inlaying grid strips → Mixing terrazzo components

4 . Applying cement bonding slurry → Spreading terrazzo mixture

5 . Rolling & leveling → Initial grinding → Fine grinding

6 . Polishing → Oxalic acid cleaning → Waxing & final polishing

Challenges of Cast-in-Place Terrazzo:

- Requires specialized raw materials and skilled construction teams.

- Large equipment (mixers, grinders) can be difficult to transport.

- Small-scale projects can face challenges finding contractors, as many only accept jobs over 100m².

- The curing process takes at least a month, delaying further interior work.

2. Prefabricated Terrazzo Round Coffee Table

Prefabricated terrazzo is manufactured in advance and installed similarly to natural stone or ceramic tiles. It comes in various sizes, thicknesses, and finishes, making it a flexible and efficient choice for furniture, flooring, and wall panels.

(1) Prefabricated Terrazzo for Walls

- Dry Hanging – Similar to stone installation, ensuring a neat and durable finish.

- Wet Sticking – Like tile application, requiring an additional polish post-installation.

(2) Thickness Specifications

- Available in 15mm, 20mm, and 30mm slab options.

- For coffee table designs, a minimum surface thickness of 80mm is recommended for structural integrity and aesthetic appeal.

Why Choose a Terrazzo Round Coffee Table?

A terrazzo round coffee table is durable, stylish, and easy to maintain, making it ideal for modern living rooms, cafes, and office lounges. Whether you choose cast-in-place for a custom fit or prefabricated for quick installation, terrazzo offers timeless charm with a contemporary twist.

With proper care and installation, a terrazzo round coffee table can be a statement piece that blends function, beauty, and lasting value.

If you want, I can also prepare a keyword-rich internal linking plan so this product page ranks for related queries like “modern terrazzo coffee table,” “epoxy terrazzo table,” and “prefabricated terrazzo furniture”, driving more targeted traffic from search engines.

Share