Terrazzo Quartz Tile

Terrazzo Quartz Tile

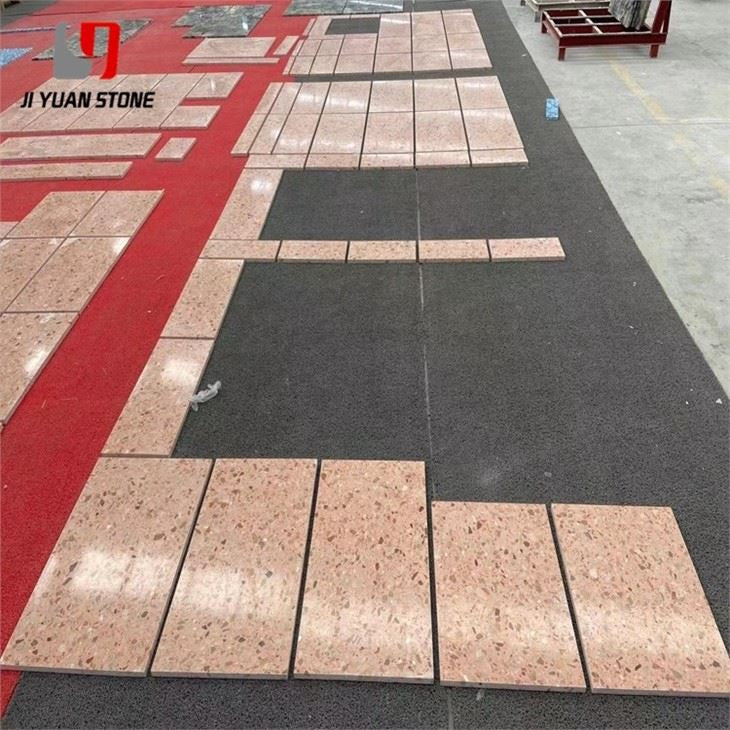

Terrazzo Quartz Tile – Precision-Crafted Flooring for Lasting Elegance & Strength

Terrazzo Quartz Tile is a durable and stylish flooring option that is perfect for high-traffic areas. Made from high-quality quartz, it offers superior strength and resistance to wear and tear. With its elegant and modern design, this tile is a great choice for both residential and commercial spaces.

| Feature | Details |

|---|---|

| Material | Terrazzo |

| Surface Finish | Polished,Honed |

| Common Slabs sizes |

|

| Common Tile sizes |

|

| Countertops Size |

|

| Vanity Tops Size |

|

| Edge Style | Bull nose, ogee, bevel, eased, polish, etc |

Terrazzo Quartz Tile is an engineered surface material made from high-grade cement, clean sand, quality stone grain, and durable pigments. Designed to meet rigorous construction standards, it is widely favored for use in residential, commercial, and institutional settings where both aesthetics and long-term performance matter.

Whether you're upgrading public walkways, staircases, or interior floors, our terrazzo quartz tiles offer a smooth, dense, and durable finish that meets the highest expectations in modern architecture.

.🧱 Material Consumption Per 100m² – Table 18-28

| Material Name | Unit | Natural Color | Add Color |

|---|---|---|---|

| Grade 32.5 Cement | kg | 1753 | 1753 |

| Clean Sand | m³ | 1.55 | 1.55 |

| Stone Grain | kg | 1853 | 1853 |

| Pigment | kg | – | 30 |

📐 Quality Standards & Specifications

✅ Main Control Items

Stone Particles:

- Must be made from hard, grindable dolomite or marble.

- Clean, debris-free with a standard particle size of 6–15mm.

- Cement must be ≥ Grade 32.5.

- Pigments used must be alkali- and light-resistant—acidic pigments are strictly prohibited.

Mixture Ratio:

- Ideal Cement: Stone Grain ratio ranges from 1:1.5 to 1:2.5 based on design.

Surface & Base Layer Bonding:

- Layers must be firmly bonded with no hollow areas beyond 400cm².

- Absolutely no cracks permitted.

🔍 General Quality Requirements

Surface Finish:

- Must be smooth and flawless.

- No cracks, pits, or visible grinding marks.

- Stone grains should appear dense and uniformly distributed.

- Pattern and color must be consistent.

Grid Strips:

- Should be straight, clean, and firmly set.

Skirting Line:

- Firmly bonded with hollow sections ≤ 300mm per room.

- Uniform height and consistent thickness across the wall.

Stairs & Step Dimensions:

- Height and width must meet design specs.

- Step height/width deviations ≤ 10mm.

- Spiral steps ≤ 5mm variation.

- Anti-slip strips must be precisely aligned.

Surface Deviation:

- Tolerances must meet Table 18-21 construction standards.

💡 Why Choose Our Terrazzo Quartz Tiles?

Our terrazzo quartz tiles not only comply with national material and quality control standards, but they also offer:

- High density and hardness

- Excellent wear resistance

- Dust-free, peel-resistant surface

- Precision construction for longevity

- Attractive finishes with or without added color pigments

Ideal for hospitals, schools, shopping malls, office buildings, and more, these tiles offer both structural integrity and aesthetic appeal.

🛠️ Engineered for Performance, Built to Last

Whether you are installing terrazzo flooring in a new build or upgrading an existing surface, our terrazzo quartz tile solution provides unmatched precision, finish, and strength. Complying with advanced material usage guidelines and bonding requirements, this product ensures you receive a reliable and visually appealing result that stands the test of time.

👉 Order now or contact us for bulk pricing and specifications tailored to your next project.

Share