Terrazzo Quartz Countertop

Terrazzo Quartz Countertop

Terrazzo Quartz Countertop – Timeless Craftsmanship Meets Modern Performance

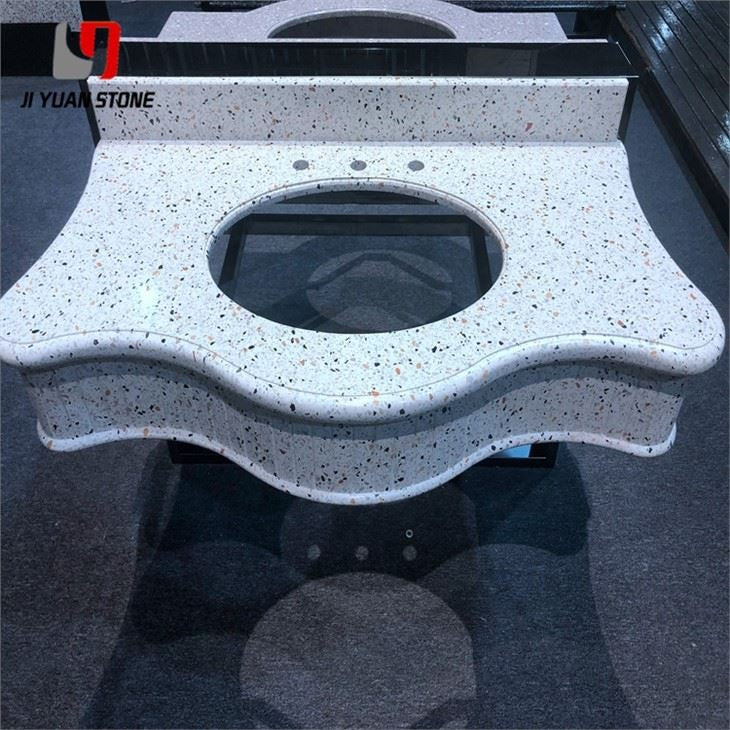

Introducing our Terrazzo Quartz Countertop, perfect for kitchens and bathrooms. Made from durable quartz, this countertop is resistant to scratches and heat, providing a long-lasting and low maintenance solution. With its elegant and modern design, it adds a touch of sophistication to any space. Upgrade your home with our Terrazzo Quartz Countertop.

| Feature | Details |

|---|---|

| Material: | Terrazzo |

| Surface Finish: | Polished,Honed |

| Terrazzo Water Aborption: | 1-3% |

| Surface Finish: | Matt, No Polished |

| Main Size: | 600*600mm |

| Customized Size: | 300*600mm, 600*600mm, 400*800mm, 800*800mm, 600*1200mm |

| Body Technology: | 50% Good Quality Body |

| Glazed Technology: | 3D HD Print |

| Customized Body: | Color Full Body, Fabric Full Body |

| Thickness: | 9.3+/-0.3MM (Thickness according to the size) |

| Usage: | Wall and Floor Tiles for Living room,bathroom,coffee shop |

| Sample: | Contact us for free sample |

| Sample ETD: | 7-10 Days After Detail Confirmed |

| Function: | Wear-resistant, Non-slip, Acid-resistant, Low water-absorption |

The Terrazzo Quartz Countertop combines centuries-old artistry with modern engineering to deliver a surface that is as beautiful as it is durable. Originating in Venice in the 16th century, terrazzo was created by inlaying scraps of stone into decorative surfaces. Introduced to China during the late Qing Dynasty, terrazzo became a popular feature in high-end spaces by the 1980s — adorning countertops, stairs, and other architectural elements in both public and residential interiors.

Today, the terrazzo quartz countertop stands out for its enhanced visual appeal over traditional cement-based terrazzo. Thanks to advancements in manufacturing, the material now offers clearer categorizations, refined processing techniques, and unmatched design versatility.

Material Composition and Processing

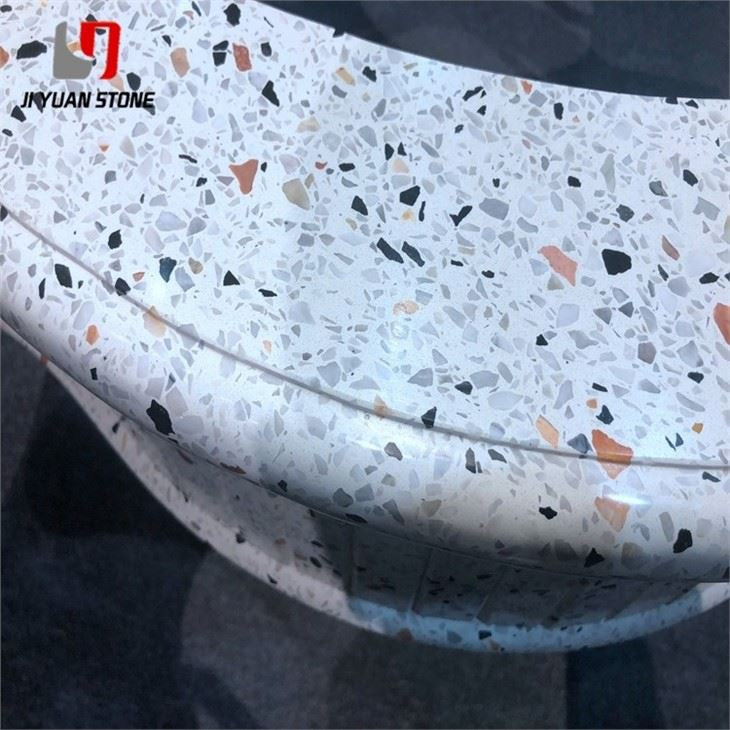

Terrazzo quartz countertops are made from a blend of:

- Crushed stone

- Glass

- Quartz stone

- Shells or artificial aggregates

These are combined with either inorganic or organic binders and processed using professional grinding, curing, polishing, and anti-fouling treatments. The countertops are custom-made on-site for a perfect fit.

Types of Terrazzo Quartz Countertops:

1 . Inorganic Terrazzo Quartz Countertops – Use inorganic concrete and natural aggregates to create a seamless, highly durable surface.

2 . Organic Terrazzo Quartz Countertops – Use epoxy resin binders, offering design flexibility but a shorter lifespan of around five years due to organic material aging.

Features & Benefits of Inorganic Terrazzo Quartz Countertops

- Seamless Design: Large installations (60–200㎡) without visible joints or cracks.

- Strong Visual Cohesion: Aggregates, shapes, and patterns merge into a harmonious aesthetic.

- Durability: Fire-resistant (Class A), non-slip, abrasion-resistant, and structurally solid.

- Customization: Choose aggregates, colors, and patterns for a unique design.

Achieving a Seamless Installation

1. Material Technical Level:

- Improve water retention, plastic resistance, and shrinkage control.

- Use expansion components to offset chemical shrinkage during curing.

2. Construction Techniques:

- Seal tightly to prevent air convection during installation.

- Apply pouring methods that prevent plastic shrinkage.

3. Base Requirements:

- Ensure adequate compressive and tensile strength.

- Keep the surface clean, dry, and contaminant-free for optimal adhesion.

With its blend of tradition and innovation, the Terrazzo Quartz Countertop offers a luxurious, sustainable, and fully customizable surface for kitchens, bathrooms, hotels, and public spaces. Whether your goal is refined elegance or bold artistic design, terrazzo quartz delivers unmatched beauty and performance that stands the test of time.

If you’d like, I can also create SEO-optimized H1, H2, and bullet-point product highlights so this page ranks for keywords like custom terrazzo countertops, seamless quartz terrazzo, and eco-friendly terrazzo kitchen surfaces. That would boost this product’s visibility even further.

Share