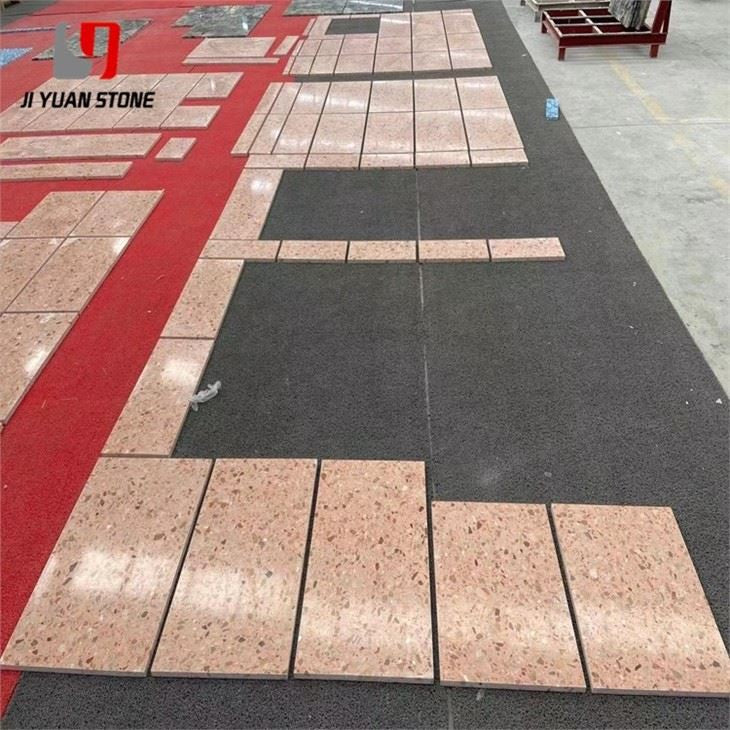

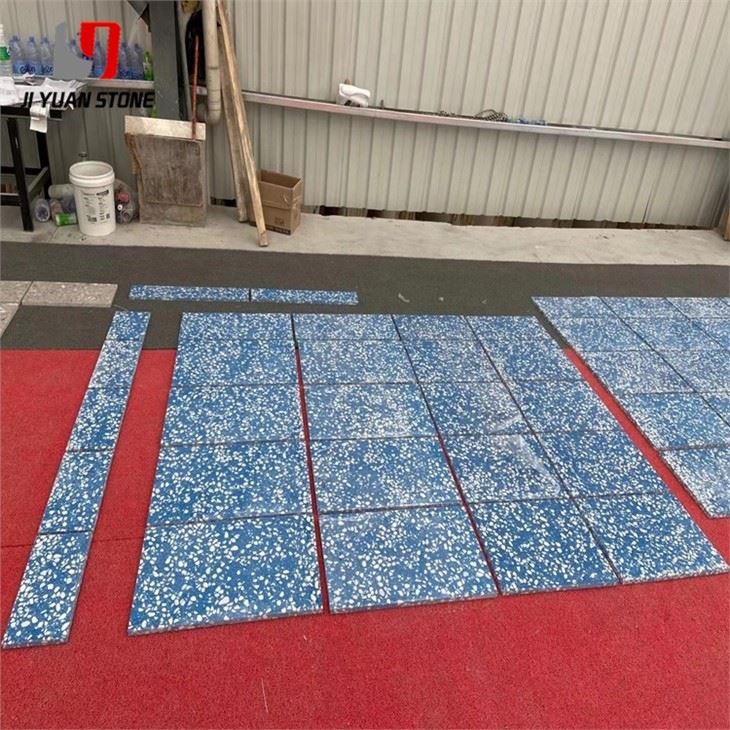

Terrazzo Floor Tiles

Terrazzo Floor Tiles

Traditional Terrazzo Floor Tiles: On-Site Pouring vs. Factory Prefabrication

Terrazzo floor tiles are a durable, low maintenance flooring option that adds a touch of elegance to any space. Made with a mixture of marble or granite chips in a cement or epoxy base, these tiles are resistant to stains, cracks, and scratches. Experience the benefits of a long-lasting, beautiful floor with Terrazzo Floor Tiles.

| Feature | Details |

|---|---|

| Material | Terrazzo |

| Surface Finish | Polished,Honed |

| Slab standard size | 3200*1600mm/2700*1800mm/2400*1600mm/2400*1200mm |

| Tile standard size | 800*800mm/900*900mm |

| Available Thickness | 2cm/2.5cm/3cm or other thickness as customization. |

Traditional terrazzo floor tiles are crafted by mixing crushed stone, glass, quartz, and other aggregates into a cement binder to form a concrete-based terrazzo surface. This mixture is ground and polished to create a smooth, attractive finish favored in many architectural projects.

There are two primary methods of traditional terrazzo production: On-Site Pouring Terrazzo and Factory Prefabricated Terrazzo. Each method offers unique advantages and considerations for various flooring needs.

1. On-Site Pouring TerrazzoOn-site poured terrazzo boasts a rich history and depends heavily on skilled craftsmanship. The terrazzo mixture is poured directly onto the installation site and polished in place, producing a seamless, uniform floor. Large areas are often divided into sections, but each section remains visually continuous and elegant.

Advantages

✔ Seamless Finish – No visible joints create a smooth, continuous surface that enhances any space.

✔ Large-Area Formation – Poured as one unit, reducing color variations within sections.

✔ Stunning Mosaic Effects – Allows for customizable decorative and artistic patterns tailored to design preferences.

Disadvantages

❌ Manual Process – Relies on craftsmanship rather than machine precision, which can affect consistency.

❌ Weaker Physical Properties – Does not benefit from high-frequency vibration or high-pressure compaction like factory products.

❌ Uneven Surface – Self-leveling and polishing may cause minor surface irregularities.

❌ Strict Construction Conditions – Requires controlled environments, prohibiting cross-operations during installation.

❌ Extended Construction Time – Needs additional curing and protection, potentially delaying project completion.

❌ Not Suitable for Walls – Limited strictly to flooring applications.

Common Issues with On-Site Pouring Terrazzo

⚠ Bonding Strength Issues – Aggregates can loosen or detach over time.

⚠ High Water Absorption – Increases risk of staining and moisture damage.

⚠ Cracking Risks – Lower density results in vulnerability to cracks.

⚠ Difficult Repairs – Damage restoration can be complicated and costly.

In contrast, factory-prefabricated terrazzo tiles are produced with advanced equipment, offering higher density, consistent quality, and faster installation. This method is ideal when durability, ease of maintenance, and efficient construction are priorities.

ConclusionTraditional terrazzo floor tiles, whether on-site poured or factory prefabricated, bring timeless beauty and versatility to flooring projects. On-site pouring is best for seamless, artistic designs in controlled environments but requires longer construction times and expert labor. Factory-prefabricated terrazzo suits projects needing consistent quality, durability, and quicker installation. Selecting the right method depends on your project's specific design, durability, and timeline needs.

Share