Terrazzo Floor And Wall Tiles

Terrazzo Floor And Wall Tiles

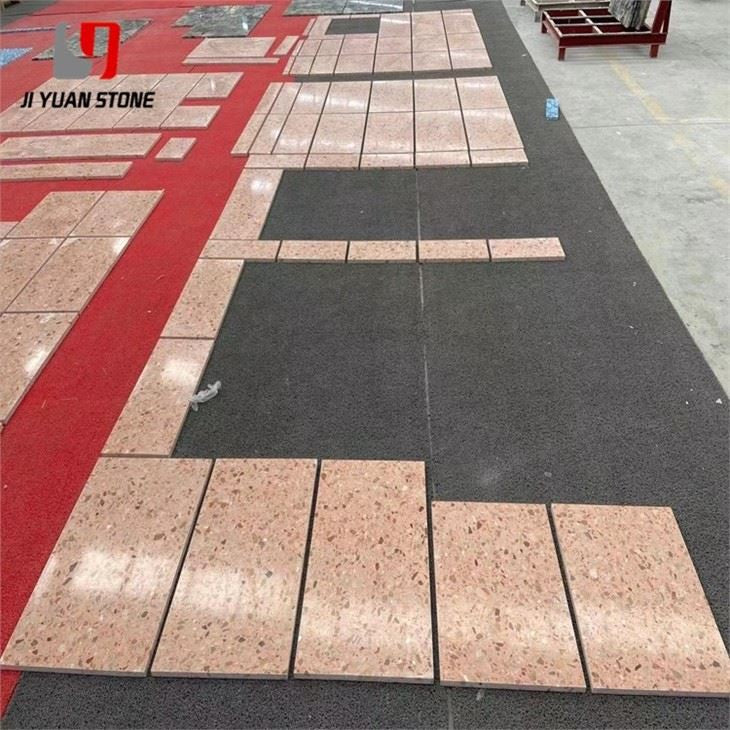

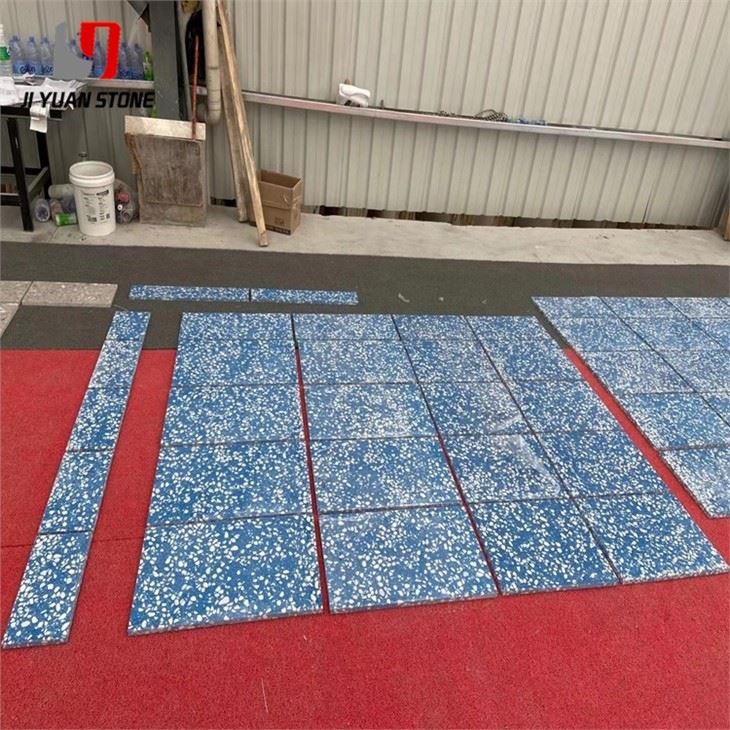

Factory Prefabricated Terrazzo: Floor & Wall Tiles

Upgrade your space with our high-quality Terrazzo Floor And Wall Tiles. Made from durable materials, these tiles are perfect for any floor or wall installation. Enhance the beauty of your home or business with a touch of elegance and sophistication. Available now in a variety of colors and patterns.

| Feature | Details |

|---|---|

| Material | Terrazzo |

| Applications | Interior wall & floor application |

| Surface Finish | Polished,Honed |

| Finishing | Polished, honed, flamed, Antiqued, bush-hammered |

| Slab standard size | 3200*1600mm/2700*1800mm/2400*1600mm/2400*1200mm |

| Tile standard size | 800*800mm/900*900mm |

| Available Thickness | 2cm/2.5cm/3cm or other thickness as customization. |

Discover the unmatched quality and versatility of factory-prefabricated terrazzo floor and wall tiles, designed for modern architectural projects. Manufactured through a sophisticated process involving material distribution, vibration, high-pressure pressing, curing, and precise cutting, these tiles offer consistent performance and aesthetic appeal comparable to traditional tiles and marble.

Advantages of Factory-Prefabricated Terrazzo

✔ Stable Quality – Produced using advanced machinery to ensure consistent, reliable performance.

✔ High Density & Strength – Features low water absorption, resulting in long-lasting durability.

✔ Mass Production – Efficient assembly-line manufacturing allows for high-volume output at competitive rates.

✔ Easy Transportation & Installation – Lightweight tiles that simplify handling and reduce installation time.

✔ Minimal Construction Delays – Streamlined production and installation help keep project timelines on track.

✔ Versatile Applications – Perfect for use on floors, walls, stairs, and countertops, adding elegance to any space.

✔ Flexible Maintenance – Individual tiles can be replaced or repaired with ease, reducing long-term upkeep costs.

Disadvantages of Factory-Prefabricated Terrazzo

❌ Visible Seams – Smaller tile sizes result in more noticeable grout lines.

❌ Color Variations – Slight inconsistencies may occur between different production batches.

❌ Dependence on Manufacturing Technology – Product quality hinges on the precision of equipment and processes used.

Common Installation Challenges

⚠ Black Seams – Grout lines may accumulate dirt, requiring meticulous cleaning and maintenance.

⚠ Paving Issues – Incorrect installation can cause hollowing or cracking, emphasizing the need for skilled labor.

Types of Factory-Prefabricated Terrazzo

1 . Square Material Pressing

This method uses a large mold to create blocks similar to natural stone, later cut into slabs with customizable thickness. It supports larger aggregates for striking, bold terrazzo patterns.

✅ Advantages:

- Allows bigger aggregates for enhanced design flexibility

- Custom thickness and pattern options available

❌ Disadvantages:

- Inconsistent raw material mixing may cause color variations

- Variance in density between center and surface layers affects uniformity

- Size limited to slabs up to 2400x1200mm

- Slightly less durable compared to other methods

2 . Plate Pressing

Utilizes molds to form uniform single-piece slabs, providing consistent density and color throughout the tile surface.

Conclusion

Factory-prefabricated terrazzo floor and wall tiles combine efficiency, durability, and style, making them an excellent choice for architects, builders, and designers. Understanding the different pressing methods and their pros and cons enables informed decisions for any project, ensuring a perfect blend of aesthetics and functionality.

Share