Terrazzo External Tiles

Terrazzo External Tiles

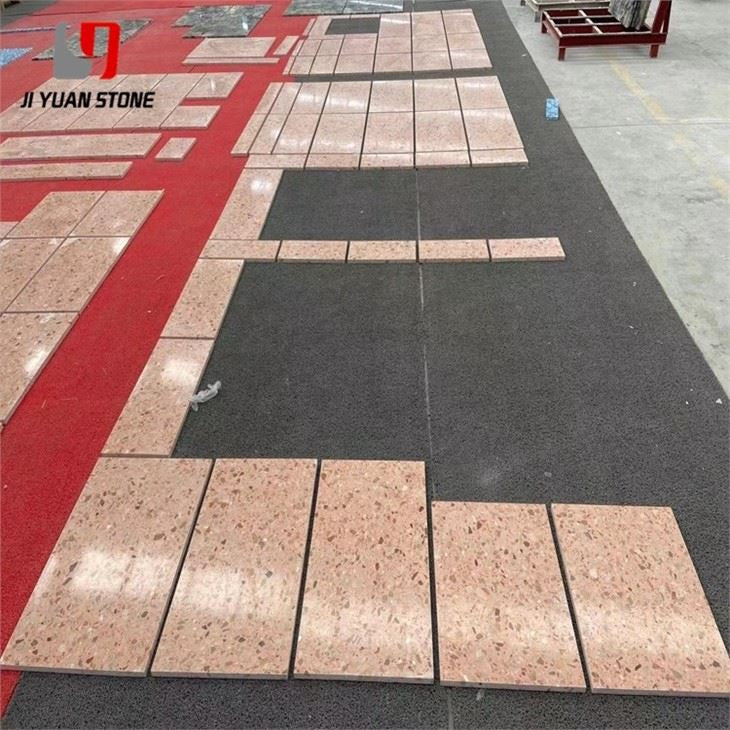

Terrazzo External Tiles – Engineered for Outdoor Endurance & Elegance

Elevate your outdoor space with our durable Terrazzo External Tiles. Made from premium materials, these tiles are perfect for any weather conditions and provide long-lasting beauty. With a range of styles and textures, create a seamless and sophisticated look for your patio, walkway, or pool deck.

| Feature | Details |

|---|---|

| Material | Terrazzo |

| Surface Finish | Polished,Honed |

| Common Slabs sizes |

|

| Common Tile sizes |

|

| Countertops Size |

|

| Vanity Tops Size |

|

| Edge Style | Bull nose, ogee, bevel, eased, polish, etc |

Discover Purchase Stones' Terrazzo External Tiles, specifically designed to withstand outdoor conditions while offering a sleek and modern look. These high-performance tiles are ideal for patios, facades, pathways, and outdoor architectural applications that demand both resilience and style.

🔹 Terrazzo External Tiles Surface – Composition and Process Control

1. Composition Materials

Proper material selection and handling are essential to achieving a consistent, high-quality terrazzo finish:

(1) Cement

Types:

- Use Portland cement, ordinary Portland cement, or slag Portland cement (strength grade ≥ 32.5) for natural or dark-colored terrazzo.

- Use white cement for light-colored terrazzo surfaces.

Restrictions: Do not use fly ash Portland cement.

Batch Consistency: Ensure the same cement batch is used for uniform coloration.

Quality Assurance: All cement must include factory certification or valid test data.

(2) Granules

Source: Produced from grindable, hard rock types such as dolomite or marble.

Properties: Sharp-edged, clean, and debris-free granules are essential.

Size: Typically 4–14mm, unless otherwise specified.

Storage Best Practices:

- Separate storage for different types, sizes, and colors.

- Store on clean mats or elevated surfaces to avoid contamination.

- Rinse and dry thoroughly before use.

(3) Pigments

- Type: Only mineral pigments that are lightfast and alkali-resistant should be used.

- Restrictions: Acidic pigments are prohibited due to potential surface degradation.

- Mixing Ratio: Generally 3%–6% of cement weight, as verified through testing.

- Note: Excess pigment may weaken the final surface strength.

- Batch Consistency: Maintain consistent color by using the same pigment batch from the same supplier.

(4) Grid Strips

- Materials: Options include copper, colored plastic, or glass strips.

- Copper Bars: Must be precisely straightened before installation.

- Specifications (Refer to Table 18-26):

| Type | Copper Bar (mm) | Glass Bar (mm) |

|---|---|---|

| Dimensions | 1200 × surface layer thickness × 1–2 | Unlimited × surface layer thickness × 3 |

🔹 2. Process Control – Ensuring Lasting Quality

Maintaining control throughout both construction and operation phases is key to the longevity and aesthetics of terrazzo external tile surfaces:

- Adhere strictly to construction standards and material guidelines.

- Verify that all mixing ratios and laying techniques align with design specifications.

- Conduct routine quality inspections to ensure surface integrity and consistency.

- Refer to Figure 18-52 for a complete schematic of the construction quality control process.

✅ Why Choose Our Terrazzo External Tiles?

- ✔️ Weather-resistant and UV-stable finish

- ✔️ High compressive strength and minimal maintenance

- ✔️ Ideal for external walls, walkways, patios, and facades

- ✔️ Precision grid inserts for decorative versatility

- ✔️ Professional-grade material selection and installation guidelines

Purchase Stones' terrazzo external tiles combine form, function, and long-term performance — built to endure and designed to impress. Whether you're an architect, contractor, or homeowner, trust in the premium quality of our outdoor terrazzo solutions.

Share