Terrazzo Concrete Wall

Terrazzo Concrete Wall

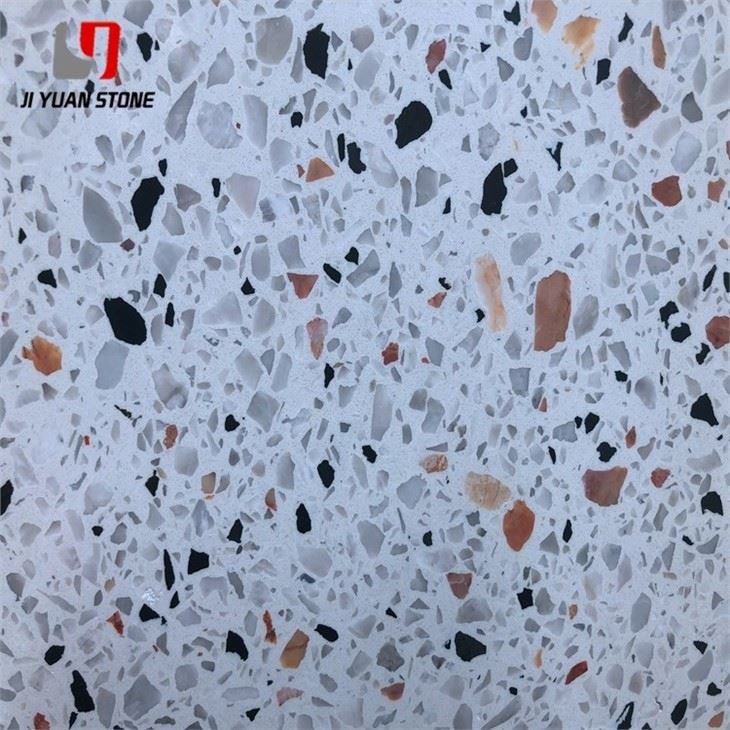

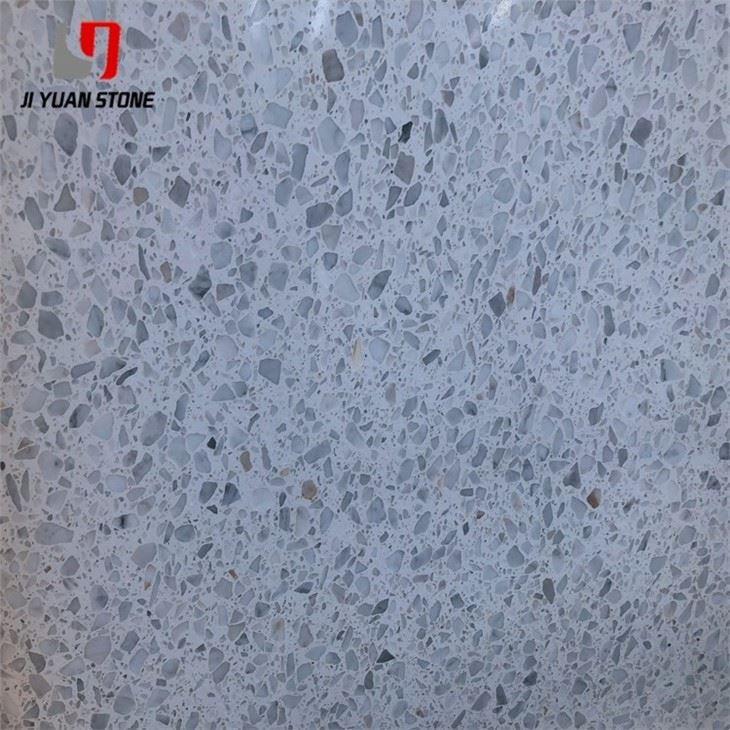

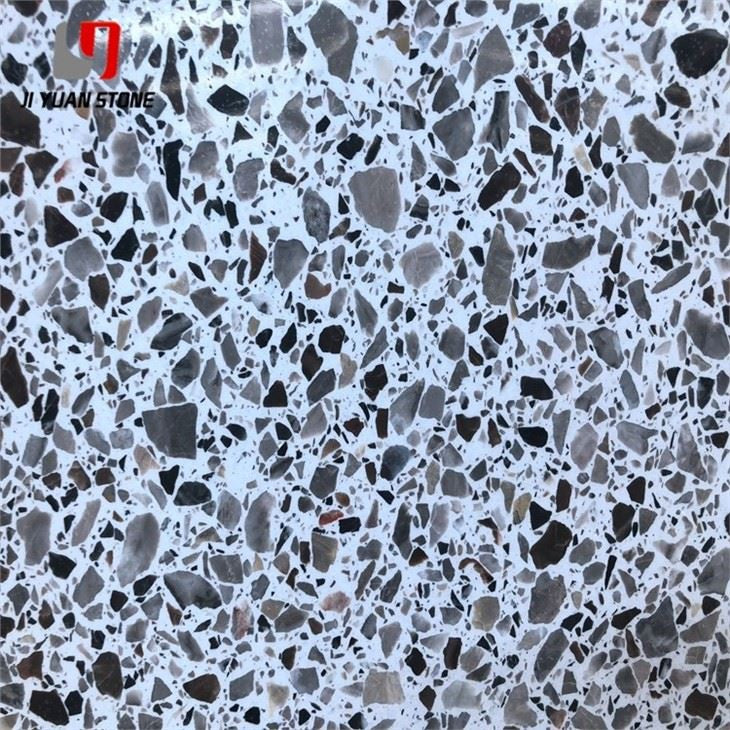

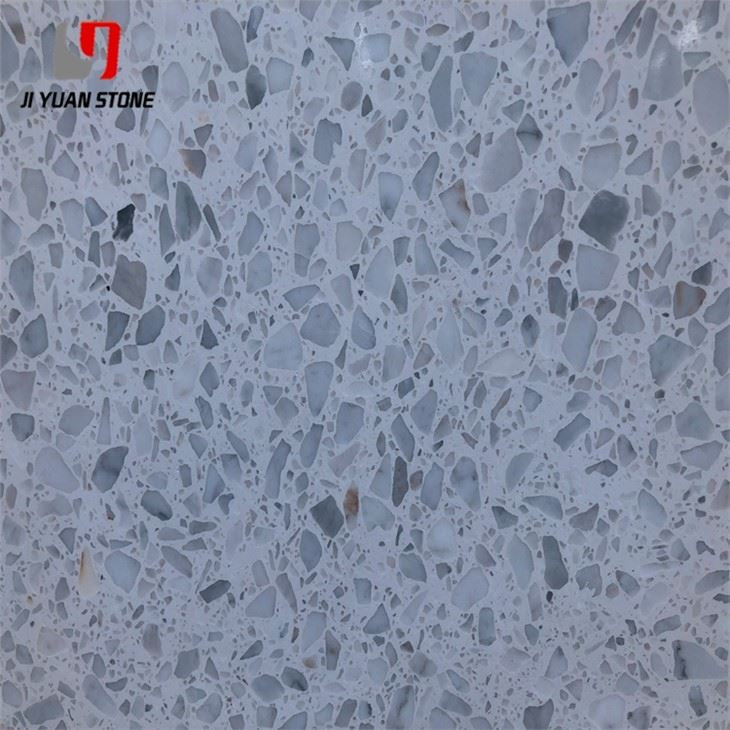

Terrazzo Concrete Wall Panels – Premium Decorative Solutions for Interiors & Exteriors

Add a touch of modern sophistication to your space with our Terrazzo Concrete Wall. Made from durable concrete, this wall offers both style and functionality. The terrazzo pattern adds a unique and elegant touch, while the concrete material guarantees long-lasting quality. Elevate your interior design with this statement wall.

| Feature | Details |

|---|---|

| Material | Terrazzo |

| Surface Finish | Polished,Honed |

| Common Slabs sizes |

|

| Common Tile sizes |

|

| Countertops Size |

|

| Vanity Tops Size |

|

| Edge Style | Bull nose, ogee, bevel, eased, polish, etc |

Our terrazzo concrete wall panels are the ideal choice for high-quality decorative finishes in civil and public buildings. Designed for interior and exterior walls, columns, door and window covers, these panels deliver exceptional durability, weather resistance, and aesthetic appeal.

Process Standard for Decorative Panels (Marble, Polished Granite, Prefabricated Terrazzo Concrete Wall)

This standard applies to decorative panels such as marble, polished granite, and prefabricated terrazzo concrete walls. All materials are selected according to the design specifications to ensure superior performance and appearance.

1. Construction Preparation

1.1 Material Requirements:

- Cement: No. 325 ordinary Portland cement (factory certified or retested if over 3 months old).

- White Cement: No. 325 white cement.

- Sand: Coarse or medium sand, sieved before use.

- Panels: Marble, polished granite, or prefabricated terrazzo concrete wall panels free from defects like surface wounds or weathering.

- Additional Materials: Plaster of Paris, copper/galvanized lead wire, stainless steel connectors, gravel, mineral pigments, 107 glue, and special plastic hoses for veneer gap filling.

1.2 Main Equipment:

Tools include measuring equipment, cutting machines, chisels, drills, levels, scaffolding, trowels, hammers, and other professional-grade installation instruments.

1.3 Working Conditions:

- Structural Acceptance: Complete all necessary preliminary works (electrical, plumbing, ventilation) before installation.

- Wall Alignment: Mark horizontal lines for accurate panel placement.

- Scaffolding Setup: Use double-row shelves or hanging baskets for outdoor high-rise installation; ensure scaffolding meets safety standards.

Our terrazzo concrete wall panels not only enhance architectural elegance but also provide long-lasting structural integrity. Whether for residential, commercial, or institutional projects, these panels meet stringent construction, aesthetic, and durability requirements.

If you want, I can also make a version optimized for Google Shopping and product schema markup so your page ranks even better in search results. That will boost both visibility and click-through rate.

Do you want me to prepare that next?

Share