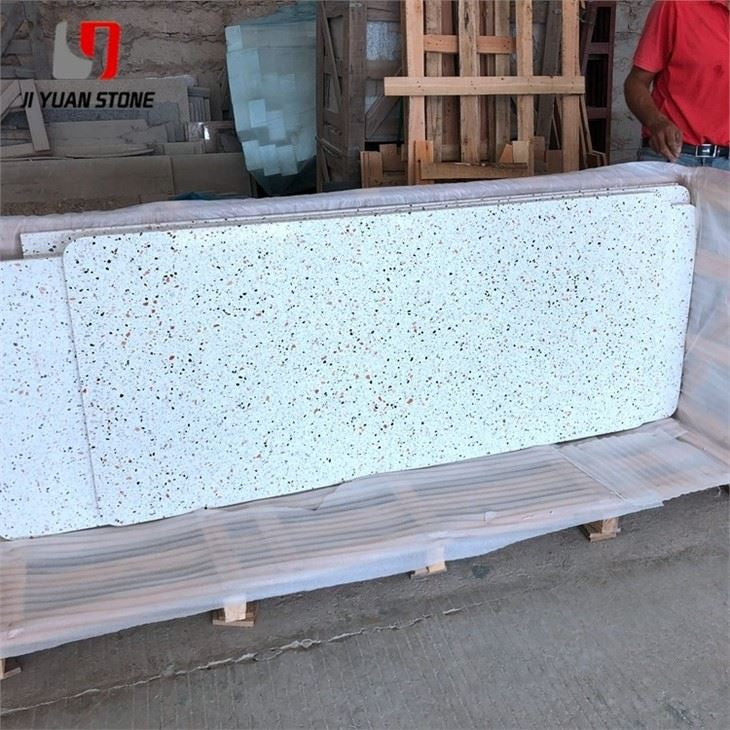

Terrazzo Concrete Table

Terrazzo Concrete Table

Terrazzo Concrete Table – The Next Evolution in Craftsmanship

Experience the perfect blend of durability and style with our Terrazzo Concrete Table. Made from high-quality materials, this table is built to last and adds a modern touch to any space. Its unique terrazzo design offers a sophisticated look, while its sturdy construction ensures long-lasting use. Elevate your home decor with our Terrazzo Concrete Table.

| Feature | Details |

|---|---|

| Material | Terrazzo |

| Product name | Cement terrazzo |

| Applications | Interior wall & floor application |

| Surface Finish | Polished,Honed |

| Finishing | Polished, honed, flamed, Antiqued, bush-hammered |

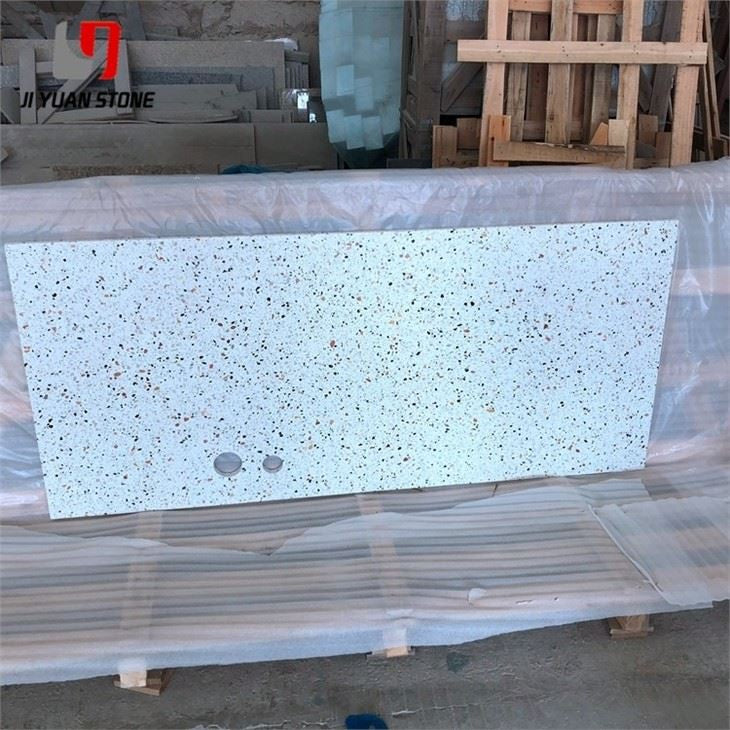

| Slab standard size | 3200*1600mm/2700*1800mm/2400*1600mm/2400*1200mm |

| Tile standard size | 800*800mm/900*900mm |

| Available Thickness | 2cm/2.5cm/3cm or other thickness as customization. |

Our terrazzo concrete table combines timeless design with cutting-edge inorganic terrazzo technology, delivering a surface that is more durable, polished, and sustainable than traditional terrazzo tables.

Inorganic Terrazzo vs. Traditional Terrazzo Concrete Tables

In the world of terrazzo craftsmanship, inorganic terrazzo is considered the upgraded version of traditional terrazzo concrete. Here’s why it outperforms the old standard:

1 . Technology Path

- Traditional: Ordinary Portland Cement + Stones.

- Inorganic: Special cement + fine aggregate + polymer + inorganic toner + patent formula for enhanced performance.

2 . Aggregate Selection

- Traditional: Limited to water-absorbent stones over 8mm in size.

- Inorganic: Compatible with all types of aggregates for more design possibilities.

3 . Construction Thickness

- Traditional: Needs more than 30mm thickness.

- Inorganic: Requires only 10mm+, saving materials and weight.

4 . Paving Process

- Traditional: Slow, difficult to achieve perfect flatness.

- Inorganic: Fast, self-leveling, smooth finish with ease.

5 . Maintenance

- Traditional: Needs 7–15 days of curing.

- Inorganic: No maintenance needed; grindable in 18–24 hours.

6 . Grinding Process

- Traditional: Water milling produces large amounts of sewage.

- Inorganic: Supports both dry and wet grinding, reducing waste.

7 . Surface Brightness

- Traditional: Around 60 degrees.

- Inorganic: 70–100 degrees for a more reflective, high-end finish.

8 . Stain Resistance

- Traditional: Poor density, prone to stains.

- Inorganic: High density, excellent stain resistance.

9 . Life Cycle

- Traditional: 3–5 years.

- Inorganic: Same life span as the architecture itself.

10 . Gaps and Seams

- Traditional: Requires metal or glass separation bars, max size 1.5×1.5m.

- Inorganic: Seamless finish for a cleaner, more modern look.

Development Potential of Inorganic Terrazzo

The rise of nanomaterials has further enhanced the potential of inorganic grindstone, offering stronger, longer-lasting surfaces with exceptional aesthetic flexibility. From commercial projects to modern home interiors, inorganic terrazzo delivers a perfect balance of practicality and design elegance.

Why Choose Our Terrazzo Concrete Table?

- Superior Strength & Durability – Outlasts traditional terrazzo.

- Premium Aesthetics – High polish, seamless finish, versatile design.

- Eco-Friendly Construction – Less waste, minimal maintenance.

- Ideal for Modern & Commercial Spaces – Perfect for homes, offices, hotels, and public areas.

Experience the future of terrazzo craftsmanship with our terrazzo concrete table—a statement piece built for beauty, performance, and longevity.

If you’d like, I can also add keyword clusters targeting “inorganic terrazzo table” and “seamless terrazzo furniture” so this page ranks for both product-specific and material-innovation searches. That would help capture both design-conscious buyers and industry professionals.

Share