Terrazzo Concrete Slab

Terrazzo Concrete Slab

Terrazzo Concrete Slabs – Durable, Stylish & Professional Installation Guidelines | Purchase Stones

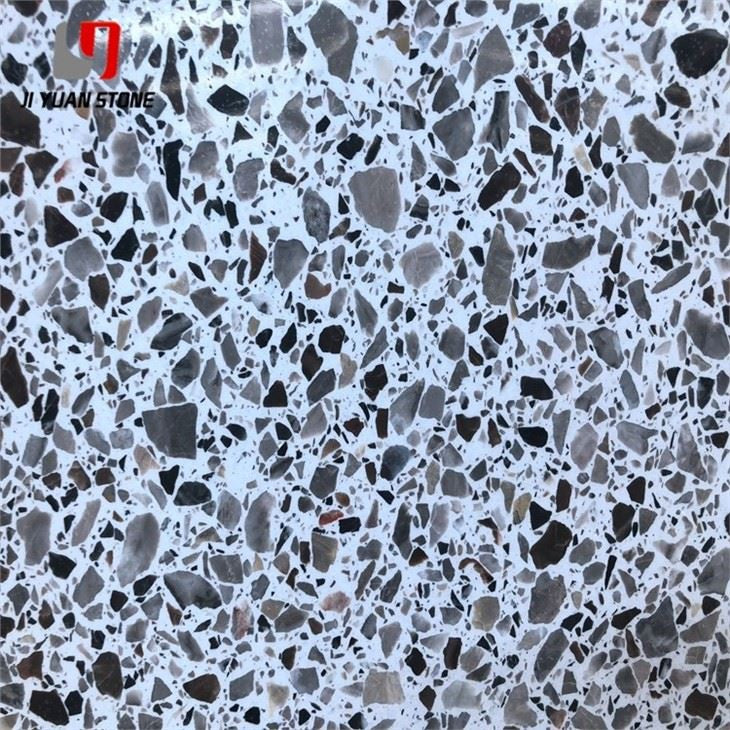

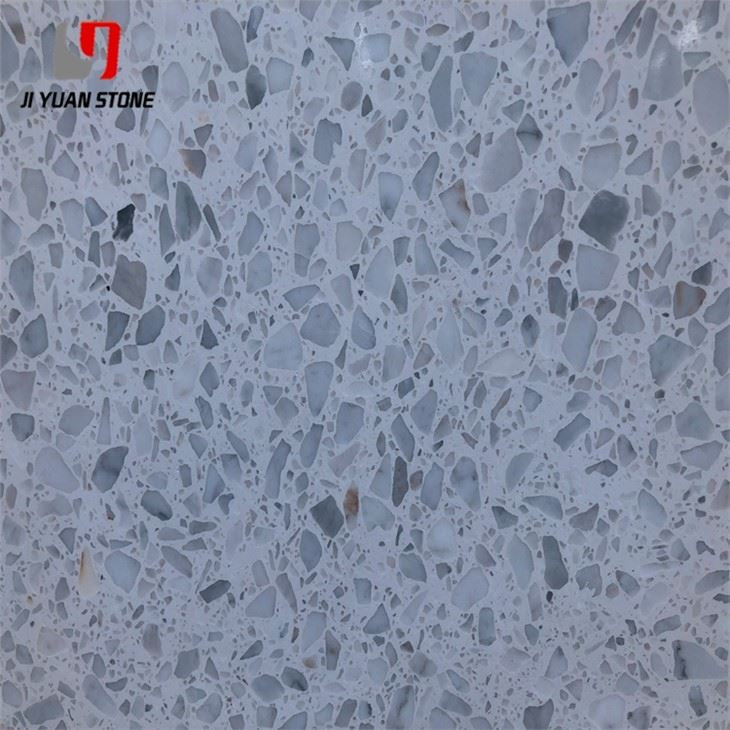

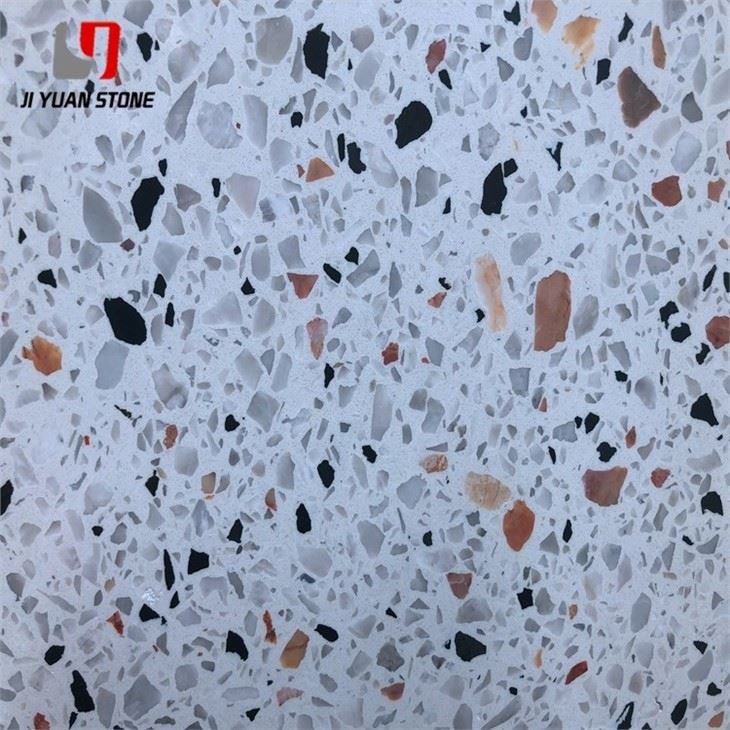

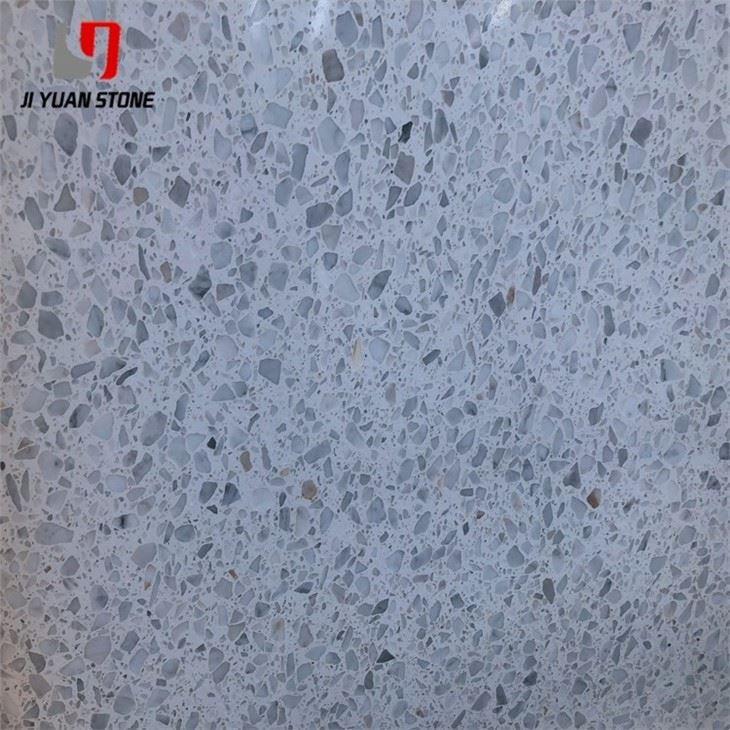

As a product expert in the concrete industry, I highly recommend our Terrazzo Concrete Slab. Made from high-quality materials, this product offers a durable and long-lasting surface for various applications. With its stylish terrazzo design, it adds a touch of sophistication to any space. Plus, its versatility makes it suitable for both indoor and outdoor use. Invest in our Terrazzo Concrete Slab for a reliable and aesthetically pleasing solution.

| Feature | Details |

|---|---|

| Material | Terrazzo |

| Surface Finish | Polished,Honed |

| Common Slabs sizes |

|

| Common Tile sizes |

|

| Countertops Size |

|

| Vanity Tops Size |

|

| Edge Style | Bull nose, ogee, bevel, eased, polish, etc |

Enhance your architectural and interior projects with premium Terrazzo Concrete Slabs from Purchase Stones — a perfect combination of elegance, durability, and modern performance. Designed for both residential and commercial applications, terrazzo concrete slabs offer long-lasting beauty, customizable styles, and exceptional resistance to wear.

Whether used for walls, floors, countertops, or outdoor facades, our terrazzo slabs are crafted with precision to deliver a smooth, stylish, and low-maintenance surface. Their unique blend of cement binders and decorative aggregates ensures they are both structurally strong and aesthetically versatile.

6. Installation Considerations for Terrazzo Concrete Slabs

6.3 Structural Considerations

Gaps in Wall and Cylinder Installations

- Issue: Inadequate gaps at the top and bottom during installation on walls and cylinders can cause structural deformation under pressure, leading to cracks in the veneer slabs due to vertical stress.

- Recommendation: Only proceed with installation after walls, columns, and load-bearing structures have fully stabilized post-settlement. Leave appropriate gaps—especially at the top and bottom—to prevent compression and cracking.

6.4 Prevention of Wall Damage and Pollution

- Issue: Veneer surfaces can be contaminated with mortar or other substances during handling and installation. If not cleaned promptly, or if unprotected post-installation, surface pollution can occur over time.

- Recommendation: Clean contaminants immediately during installation and protect the finished product from acid-base chemicals, colored liquids, and other potential pollutants to preserve the slab’s appearance and integrity.

6.5 Considerations for Large Outdoor Veneer Panels

Issue: Large veneer panels exposed to direct sunlight are prone to temperature-induced expansion and contraction, potentially causing detachment or damage.

Recommendations:

- Dry Hanging Method: Ideal for sun-exposed areas; maintains clarity and beauty while preventing detachment from thermal movement.

- Wet Hanging Method: If used, include deformation joints (split grid or open plate seam methods) to absorb expansion and contraction.

- Anti-Alkali Measures: Implement protective measures to prevent efflorescence, safeguarding both appearance and structural durability.

7. Quality Records

To ensure long-term performance and compliance with construction standards, maintain:

- 7.1 Material Certifications: Factory certificates for terrazzo concrete slabs, polished granite, prefabricated terrazzo slabs, and related materials.

- 7.2 Quality Inspection Documentation: Detailed inspection and evaluation forms outlining compliance, observations, and corrective actions for the sub-project.

Why Choose Purchase Stones Terrazzo Concrete Slabs?

- Superior Durability: Resists cracking, staining, and weather damage.

- Design Flexibility: Available in various colors, aggregates, and finishes.

- Easy Maintenance: Non-porous surfaces for simple cleaning.

- Proven Performance: Suitable for both indoor and outdoor high-traffic areas.

Order your Terrazzo Concrete Slabs from Purchase Stones today for a long-lasting, elegant solution backed by professional installation guidelines that ensure flawless results.

Share