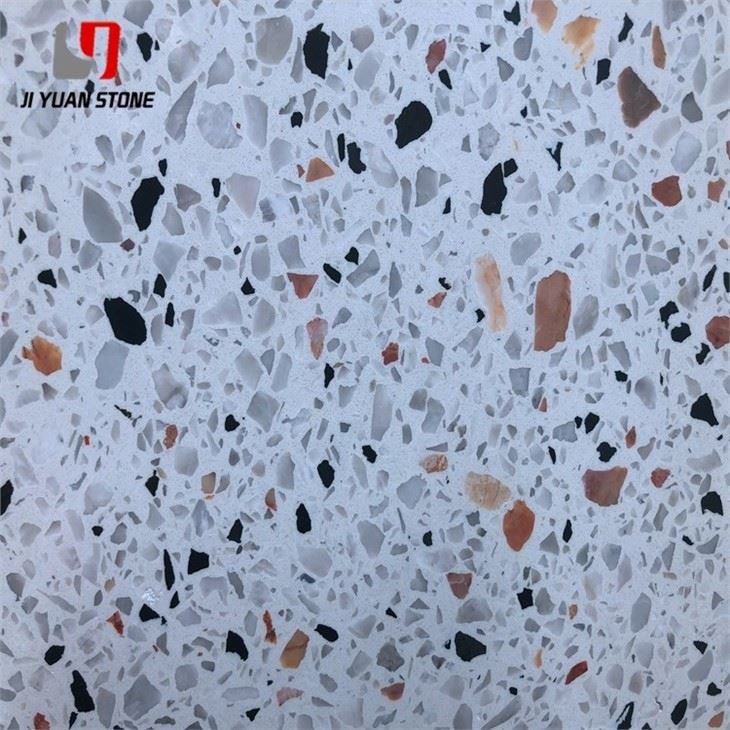

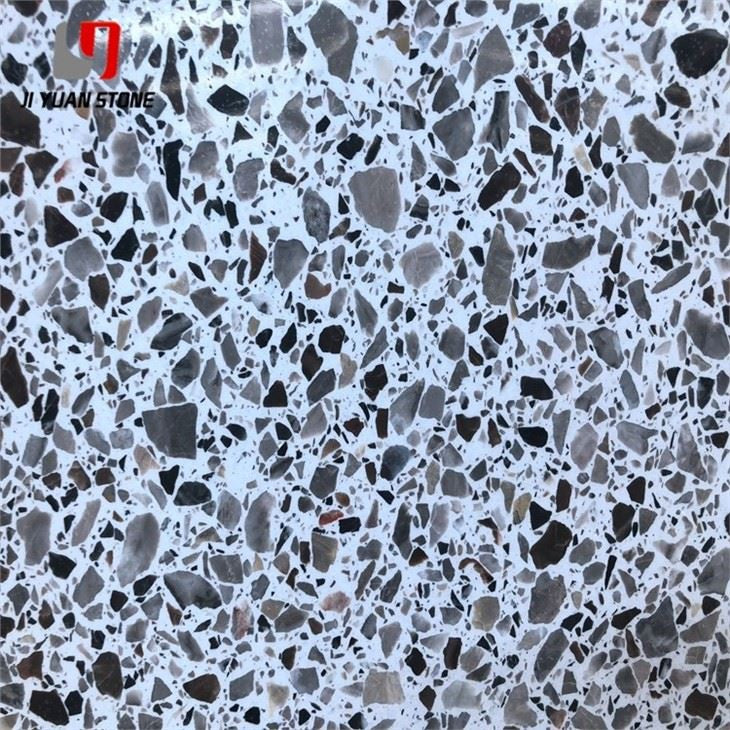

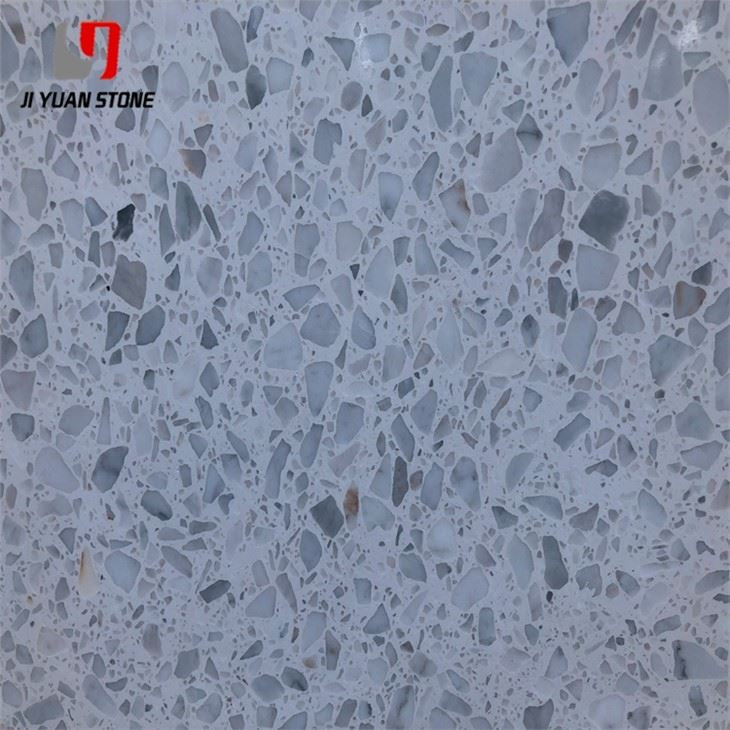

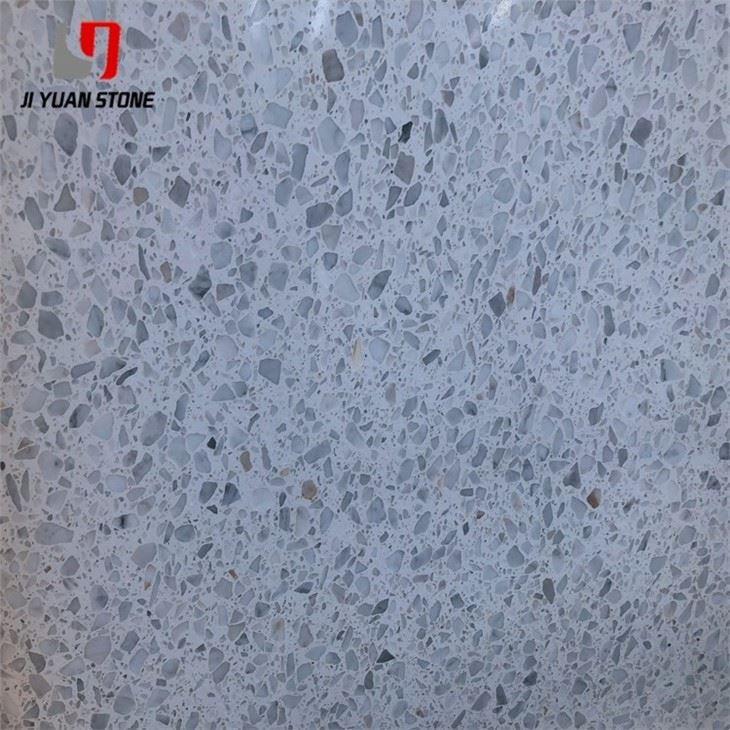

Terrazzo Concrete Floor Tiles

Terrazzo Concrete Floor Tiles

Terrazzo Concrete Floor Tiles – Durable, Elegant & Professional Installation Guide | Purchase Stones

Terrazzo Concrete Floor Tiles are a durable and stylish choice for any flooring project. Made from high-quality concrete, these tiles offer both strength and beauty, providing a long-lasting and visually appealing solution for your home or business. Transform your space with the timeless elegance of Terrazzo Concrete Floor Tiles.

| Feature | Details |

|---|---|

| Material | Terrazzo |

| Surface Finish | Polished,Honed |

| Common Slabs sizes |

|

| Common Tile sizes |

|

| Countertops Size |

|

| Vanity Tops Size |

|

| Edge Style | Bull nose, ogee, bevel, eased, polish, etc |

Add timeless style and unmatched durability to your floors with Terrazzo Concrete Floor Tiles from Purchase Stones. Perfect for residential, commercial, and public spaces, these tiles combine elegance with long-lasting performance. Crafted from high-quality cement binders and decorative aggregates, terrazzo tiles offer a smooth, polished finish that is both functional and visually appealing.

To maximize the lifespan and pristine appearance of your terrazzo concrete floor tiles, proper protection during and after installation is essential.

5. Finished Product Protection

5.1 Protection of Installed Surfaces

- Immediate Action: After installing terrazzo concrete floor tiles, polished granite, prefabricated terrazzo columns, and door or window covers, protect all external corners with wooden boards.

- Mortar Residue Removal: Clean any mortar residue from door and window frames immediately. For aluminum alloy frames, apply a protective film in advance to avoid contamination.

5.2 Wall Surface Protection

- After walls are finished with terrazzo tiles, polished granite, or prefabricated terrazzo tiles, cover them with adhesive or plastic films to prevent pollution and physical damage.

5.3 Bonding Layer Care

- Protect the bonding layer from air drying, direct sunlight, water exposure, impacts, and vibrations until it is fully set to ensure optimal adhesion and durability.

5.4 Care During Scaffold Removal

- Exercise caution when dismantling scaffolding to avoid damaging the finished walls and floors.

6. Quality Issues to Monitor

6.1 Uneven Joints & Height Differences

- Causes: Poor base layer preparation, low-quality boards, skipping trial assembly, incorrect installation techniques, or overfilling during grouting.

- Effects: Misalignment, displacement, uneven joints, and visible height differences between tiles.

6.2 Hollowing (Voids Under Tiles)

- Causes: Improper grout mixing, incorrect consistency, mortar not flowing properly, excessive cleaning force, or inadequate curing.

- Effects: Voids beneath the tiles, especially around steel mesh, leading to weakened adhesion.

6.3 Cracking

- Causes: Low-quality terrazzo tiles, poor positioning, insufficient gaps during wall installation, or exposure to external forces.

- Effects: Irregular cracks, often along dark seams of color patterns or other stress points.

Why Choose Purchase Stones Terrazzo Concrete Floor Tiles?

- Elegant & Versatile Designs – Choose from various colors, patterns, and finishes.

- Exceptional Durability – Resistant to heavy wear, stains, and moisture.

- Low Maintenance – Non-porous surface for easy cleaning.

- Professional Quality Standards – Backed by expert installation and care guidelines.

By following these professional installation and protection recommendations, you can ensure your terrazzo concrete floor tiles maintain their integrity, durability, and beauty for decades.

Order now from Purchase Stones and invest in flooring that blends luxury, performance, and long-lasting appeal.

Share