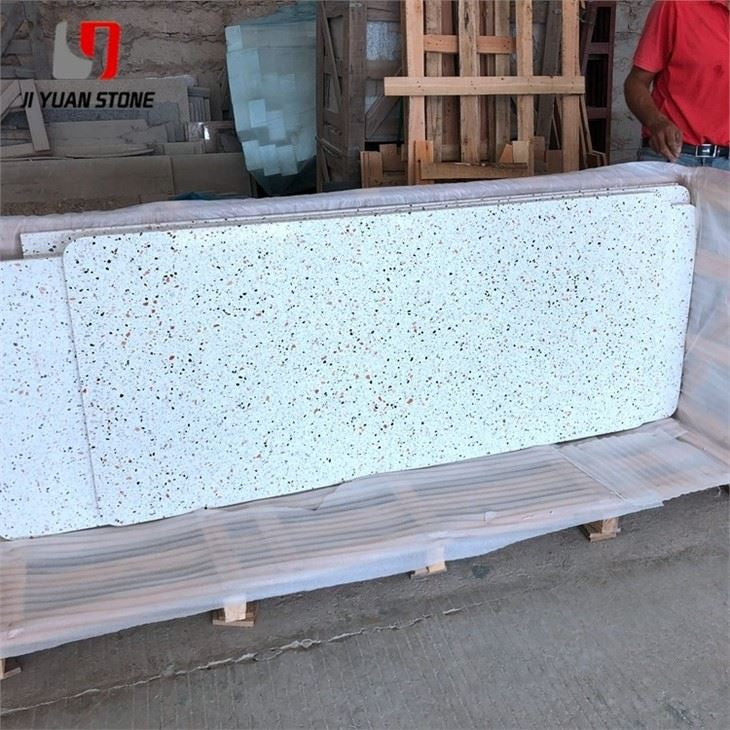

Terrazzo Concrete Countertop

Terrazzo Concrete Countertop

Terrazzo Concrete Countertop – Strength, Style & Crack Prevention

Made from a durable and stylish Terrazzo concrete material, this countertop is a perfect addition to any kitchen or bathroom. Its sturdy surface provides a long-lasting and low-maintenance option for your home. With its unique design, it will add a touch of elegance to any space.

| Feature | Details |

|---|---|

| Material | Terrazzo |

| Product name | Cement terrazzo |

| Applications | Interior wall & floor application |

| Surface Finish | Polished,Honed |

| Slab standard size | 3200*1600mm/2700*1800mm/2400*1600mm/2400*1200mm |

| Tile standard size | 800*800mm/900*900mm |

| Available Thickness | 2cm/2.5cm/3cm or other thickness as customization. |

The terrazzo concrete countertop is more than just a surface—it’s a blend of modern design, timeless durability, and practical performance. Known for its unique charm and versatile use, terrazzo has become a favorite in residential, commercial, and industrial settings.

However, like any construction material, terrazzo countertops can develop cracks if not properly installed or maintained. Understanding why cracks form and how to prevent them is essential for a long-lasting, flawless finish.

Common Causes of Cracks in Terrazzo Concrete Countertops

1 . Foundation & Base Issues

- Poor backfill, uneven base surfaces, or winter freezing of the base layer.

- Inconsistent ditch cover levels and insufficient grouting.

- Excessive foundation brick wall height near doorways, causing thin or uneven cushion layers.

2 . Structural Settlement

- Tight construction timelines leading to unstable settlement.

- Cushion layer and surface course poured too closely together, causing shrinkage cracks.

- Improperly fixed hidden cable pipelines or high pipeline positioning.

3 . Surface Preparation Problems

- Dirty or improperly cleaned base layers.

- Loose or insufficiently poured joints in precast concrete slabs.

- Concentrated ground loads leading to stress cracks.

4 . Poor Surface Division

- Narrow and elongated grid divisions, which are prone to cracking.

Effective Crack Prevention for Terrazzo Concrete Countertops

1 . Proper Backfilling & Layer Compaction

- Backfill in layers and compact thoroughly.

- Avoid debris or frozen blocks, especially in winter construction.

- Use block pouring or reinforcement measures in large areas to reduce settlement cracks.

2 . Doorway & Entrance Reinforcement

- Keep brick wall height below the cushion’s lower skin.

- Maintain proper cushion thickness and use grid strips on both sides of doorways to prevent cracks.

3 . Curing & Reinforcement

- Allow the concrete cushion to cure fully before adding the terrazzo surface layer.

- For uneven loads or large spans, reinforce with two-way Ф6@150–200mm steel bars for better strength and rigidity.

Why Terrazzo Concrete Countertops Stand Out

- Durability: Resistant to heavy wear, moisture, and stains.

- Customizable Design: Available in endless colors, patterns, and aggregate mixes.

- Low Maintenance: Easy to clean and maintain for years of service.

- Sustainable Choice: Made from natural stone, glass, and recycled materials.

Terrazzo concrete countertops combine artistry, engineering precision, and material strength. With proper installation and maintenance, you’ll enjoy a smooth, crack-free surface that elevates your space with modern elegance and timeless appeal.

If you’d like, I can also prepare LSI keywords and an internal linking strategy for this page so it ranks for searches like custom terrazzo counters, terrazzo crack prevention, and durable concrete countertops. That will help boost organic reach across multiple relevant queries.

Share