Terrazzo Concrete Benchtop

Terrazzo Concrete Benchtop

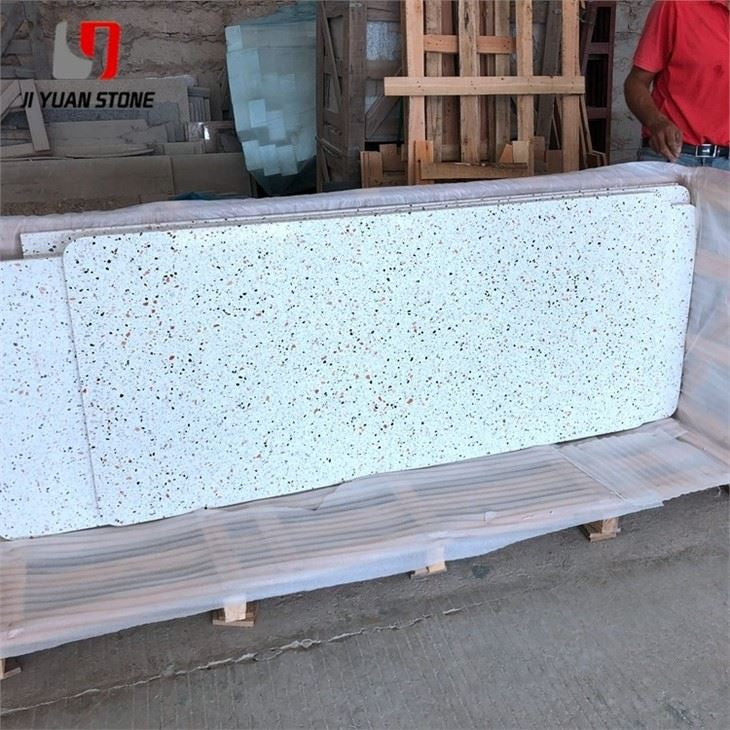

Terrazzo Concrete Benchtop – Strength Meets Style

Introducing the Terrazzo Concrete Benchtop - the perfect combination of strength and beauty. Made from high-quality concrete, it offers durable and long-lasting performance. Its unique terrazzo finish adds a touch of elegance to any space. Upgrade your countertops with this expertly crafted benchtop.

| Feature | Details |

|---|---|

| Material | Terrazzo |

| Product name | Cement terrazzo |

| Applications | Interior wall & floor application |

| Surface Finish | Polished,Honed |

| Finishing | Polished, honed, flamed, Antiqued, bush-hammered |

| Slab standard size | 3200*1600mm/2700*1800mm/2400*1600mm/2400*1200mm |

| Tile standard size | 800*800mm/900*900mm |

| Available Thickness | 2cm/2.5cm/3cm or other thickness as customization. |

The terrazzo concrete benchtop is where craftsmanship and durability meet timeless elegance. Whether for residential kitchens, commercial counters, or designer workspaces, terrazzo offers exceptional strength, custom finishes, and a sleek modern look.

Construction & Installation Guidelines

To ensure your terrazzo concrete benchtop delivers long-term performance, expert installation is key:

1 . Seam and Cable Management

- Board seams and end seams of precast concrete slabs must be densely poured with fine stone concrete.

- Hidden cable ducts should be spaced out, with at least a 20mm concrete protective layer above the pipeline.

- If cable ducts must be placed close together, add a reinforced mesh in the cushion for stability.

2 . Base Layer Preparation

- Make sure the surface is flat, strong, stable, and free from debris.

- The bonding surface must be clean and secure for maximum adhesion.

3 . Concrete & Mortar Consistency

- Use dry, hard mortar or concrete to minimize shrinkage cracks.

- Avoid overly wet mixes to prevent hollow cracks on the surface.

4 . Grid Division

- When dividing the terrazzo surface into grids, avoid narrow or elongated strips to reduce shrinkage-related cracks.

The Beauty of Simplicity

How amazing is the terrazzo concrete benchtop?

The simpler the design, the more elegance and agility it brings to your space. Terrazzo, also known as grindstone, is crafted by mixing crushed stone, glass, quartz, and other aggregates into cement binders, then grinding and polishing to perfection.

Types of Terrazzo Concrete Benchtop

- Inorganic Grindstone – Made with cement bonding material for exceptional strength.

- Organic (Epoxy) Grindstone – Uses epoxy resin as the binder for enhanced color vibrancy and a seamless finish.

Depending on the construction process, terrazzo can be:

- On-Site Terrazzo – Installed and polished in place.

- Prefabricated Terrazzo – Manufactured off-site and installed as ready-made slabs.

Performance & Aesthetics

A high-grade terrazzo concrete benchtop (commercial terrazzo) polished to 70–90 degrees brightness achieves marble-like beauty while being dust-proof, anti-skid, and wear-resistant.

- Surface Hardness: 6–8 on the Mohs scale.

- Custom Options: Prefabricated slabs can be spliced seamlessly, with fully customizable colors and patterns to match your design vision.

Why Choose Our Terrazzo Concrete Benchtop?

- Crack-resistant and long-lasting.

- Anti-skid, dust-proof, and wear-resistant.

- Customizable colors and finishes.

- Suitable for both residential and commercial interiors.

Transform your countertops with a terrazzo concrete benchtop—a perfect combination of modern style, structural strength, and personalized design.

If you want, I can also prepare an LSI keyword set for this page so it ranks for related searches like custom terrazzo countertops, commercial terrazzo benches, and prefabricated terrazzo slabs. That would boost organic traffic from multiple intent-based queries.

Share