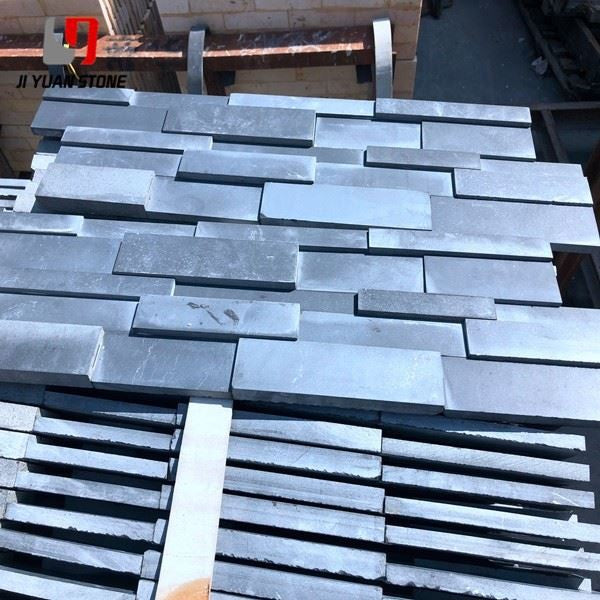

Stone Veneer Panel

Stone Veneer Panel

Upgrade the aesthetic of your home with our Stone Veneer Panel. Made with high-quality materials, our panel provides a durable and realistic stone look without the weight or expense of traditional stone. Enhance your space with a touch of elegance and sophistication.

| Feature | Details |

|---|---|

| Product | Stone Veneer Panel |

| Surface | Split face |

| Thickness | 0.8-1.2cm,1-1.5cm,1-2cm,1.5-2.5cm,2.5-3.5cm etc |

| Finished Products | Floor tiles, Wall cladding, Countertops, Windowsills, Special-shaped tiles, Small slabs, Swimming pool, stairs, steps, wall panel, flooring, veneers, slabs, coping tiles, bathtub etc |

| Colour |

Many colors for choice |

Hand-Formed Curved Line Processing for Stone Veneer Panels

Although hand-formed curved line technology is considered outdated, it remains the mainstream processing method for many stone veneer panel manufacturers. This is due to the lack of advanced machinery, such as:

✅ Vertical lathes

✅ Engraving machines

✅ Five-axis machining centers

For example, in spiral staircase inclined positions, most manufacturers lack five-axis machining centers, making hand-formed curved lines the only viable option.

Even though modern carving machines are replacing traditional methods, hand-shaped curved lines remain an essential skill that showcases high-level craftsmanship in stone processing. It is crucial to preserve and document this technique for future generations.

Process Flow of Hand-Shaped Curved Line Processing

1️⃣ Template Making

2️⃣ Line Drawing

3️⃣ Roughing

4️⃣ Finishing

5️⃣ Splicing & Numbering

6️⃣ Rough Grinding

7️⃣ Water Grinding & Polishing

8️⃣ Delivery

9️⃣ Inspection

🔟 Packaging

1. Production of Templates

Hand-formed bends require at least two templates:

1️⃣ Curve Template – for extending the trajectory.

2️⃣ Section Template – for shaping the cross-section.

Both templates are indispensable for ensuring accuracy.

Material Selection for Templates

- If small quantities are being processed → Use 3mm plywood.

- If large quantities are being processed → Use 3mm aluminum alloy plate or steel plate to prevent deformation.

Template Cutting & Finishing

- Templates are cut using a water jet machine.

- After cutting, burrs are polished off with sandpaper to ensure a smooth surface.

This process ensures that curved lines are precise and consistent, maintaining high-quality stone veneer panel production.

Share