1

/

of

13

Stone Quartz Veneer

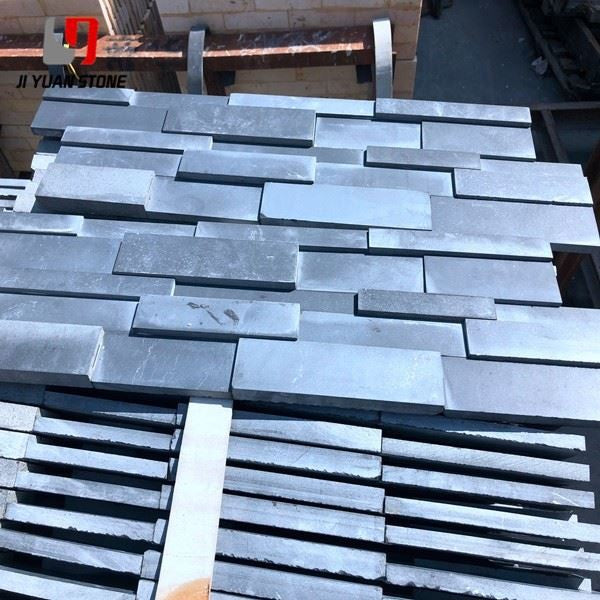

Stone Quartz Veneer

As a product expert, I offer Stone Quartz Veneer that is a durable and versatile material for your building needs. With a natural stone appearance and easy installation process, it adds a touch of elegance to any project. Made of 90% quartz, it resists scratching, heat, and stains, ensuring longevity and low maintenance for your space.

| Feature | Details |

|---|---|

| Product | Stone Quartz Veneer |

| Surface | Split face |

| Thickness | 0.8-1.2cm,1-1.5cm,1-2cm,1.5-2.5cm,2.5-3.5cm etc |

| Finished Products | Floor tiles, Wall cladding, Countertops, Windowsills, Special-shaped tiles, Small slabs, Swimming pool, stairs, steps, wall panel, flooring, veneers, slabs, coping tiles, bathtub etc |

| Colour |

Many colors for choice |

Stone Quartz Veneer Finishing & Splicing Process

1. Finishing Process

During stone quartz veneer finishing, production workers should:

- Check processing boundaries and contour lines to ensure they do not exceed the standard.

- Use a standard template for verification.

- Leave a 1mm machining allowance when finishing.

Depth Check

- Use a vernier depth check ruler to inspect 5 to 10 points at the molding area.

- Some workers may attempt to reduce production time and increase output by manipulating the depth of curved line modeling:

- The two ends of the curved line may meet the upper section template, but the middle part is often shallow with less modeling.

Grinding Tools for Curved Lines

Common grinding tools include:

- Slices

- Diamond steel discs

- Sand-coated diamond sheets

- Glass sheets

- Diamond wheels

2. Splicing Process

Splicing is a crucial step in the processing of hand-shaped curved lines.

Splicing Procedure

1. Check Quality:

- After finishing the bending line, check the processing quality of multiple bending lines.

- Ensure the extended trajectory curve is smooth and fluent.

2. Splicing Test:

- The processed bending lines should be spliced according to the splicing diagram in the production processing sheet.

- If there are deviations, adjustments must be made.

Corrections for Deviations

- Grind the angle of chamfering on the curved line.

- Smooth out the curve of the extension track.

- Refine the shape of the joint interface to ensure a seamless connection.

- If the extension track curve is not smooth, extend the grinding length.

Common Production Errors

- Some workers attempt to save effort by grinding less than 100mm, causing visible bumps and depressions in the final product.

- Proper grinding should be extended for a smoother finish.

By following these steps carefully, the stone quartz veneer achieves a precise, high-quality finish with seamless splicing for a superior decorative appearance.

Share