Sodalite Stone Slab

Sodalite Stone Slab

Sodalite Stone Slab – Natural Elegance with Superior Durability

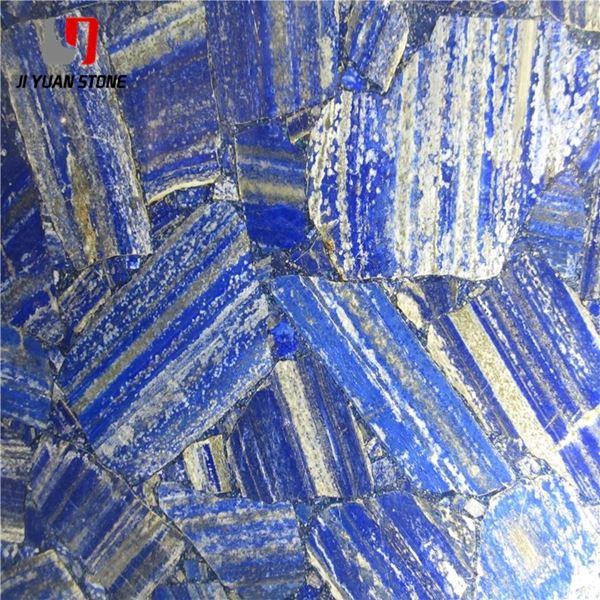

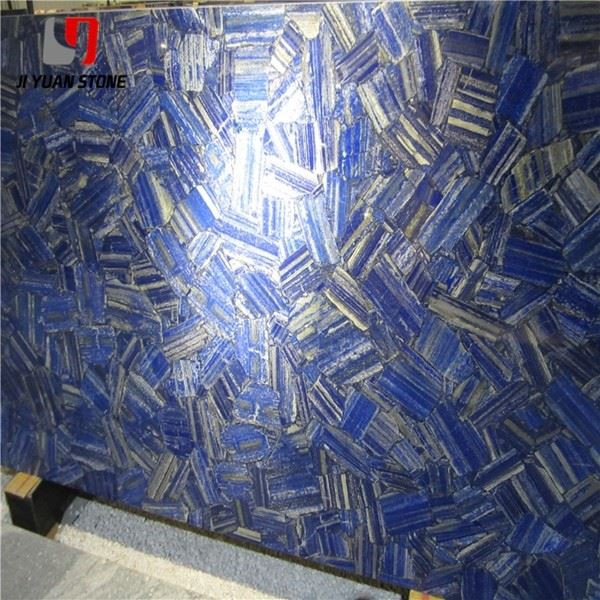

Crafted from the beautiful and unique Sodalite Stone, our slab is perfect for adding a touch of elegance and sophistication to any space. With its rich and deep blue tones, this natural stone brings a calming and grounding energy, making it ideal for meditation or relaxation rooms. Upgrade your interior design with our Sodalite Stone Slab.

| Feature | Details |

|---|---|

| Product Name | Sodalite Stone Slab |

| Material | 100% Sodalite Agate Gemstone |

| Surface Finished | Honed,Polished |

| Finished Products | Floor Tiles, Wall Cladding, Countertops, Windowsills, Special-Shaped Tiles, Small Slabs, Swimming Pool, Steps, Wall Panel, Flooring, Veneers, Slabs, Coping Tiles etc. |

| Color | Yellow,Black,White,Red,Purple Wood,Green,Grey,Pink,Rainbow,Pink,Tiger Eye etc |

| Size | Any sizes customized are welcome |

| Edge Available | Polished, Bush Hammer, Flat, Flamed, Eased, Beveled, Bullnose, Ogee, Cove, Dupont, laminated, non-laminated and etc. |

| Thickness | 10/15/18/20/25/30mm etc |

| Usage | Indoor/Outdoor Decoration, For floor or wall, Counter tops, Vanity tops |

| Packing | Seaworthy Wooden Crate |

The Sodalite Stone Slab is a luxurious natural stone renowned for its rich blue tones and striking veining, perfect for elevating the aesthetic of walls, floors, and staircases. When selecting sodalite stone, keep in mind that stones sharing the same name can vary significantly; always prioritize large sample approval to ensure your project’s consistency and quality.

🔷 Key Design & Selection Considerations

1 . Texture Direction and Pattern Matching

The direction of the stone’s natural texture is critical. Design plans should clearly indicate texture orientation and include detailed stone processing diagrams. Fabricators use these drawings to perform pre-splicing, pattern matching, color selection, and size proofing, ensuring a seamless and visually stunning installation.

2 . Suitability for Use

Natural marble, including sodalite, is generally not recommended for outdoor use or areas exposed to acids. Additionally, avoid using sodalite for floors with frequent water exposure such as swimming pools, both indoor and outdoor, to prevent efflorescence, rust spots, and water stains.

🔷 Maintenance & Protective Treatments

To maximize the lifespan and preserve the beauty of sodalite stone slabs, especially when used on floors or high-traffic areas:

- Apply stone surface protectants tailored to the stone’s location and function. Options include anti-fouling, oil-proof, waterproof, color-enhancing, penetrating, and impermeable treatments.

- For materials like travertine, sandstone, and cultural stones that are less resistant to pollution, protective agents are essential for walls, floors, and columns.

- When using travertine on the floor, first fill stone holes with special glue before applying protective agents.

🔷 Ideal Use for Stairs

For stone staircases, select sodalite slabs with good bending resistance combined with granite or other stones known for wear resistance and low water absorption. This ensures both safety and long-term durability.

🔷 Structural & Installation Guidelines

- Design the deformation joints (including seismic, expansion, and settlement joints) in the stone veneer carefully to maintain both the stone’s flexibility and the overall integrity of the finish.

- Proper joint design prevents cracking and damage caused by building movement, ensuring a stable and beautiful surface over time.

Why Choose Sodalite Stone Slabs?

- Vibrant and natural blue hues for elegant interior spaces

- Carefully designed and fabricated to maintain texture consistency

- Protective treatments to extend lifespan and resistance to stains

- Suitable for walls, floors, stairs, and decorative architectural elements

Elevate your design projects with premium Sodalite Stone Slabs—where natural beauty meets practical performance.

Share