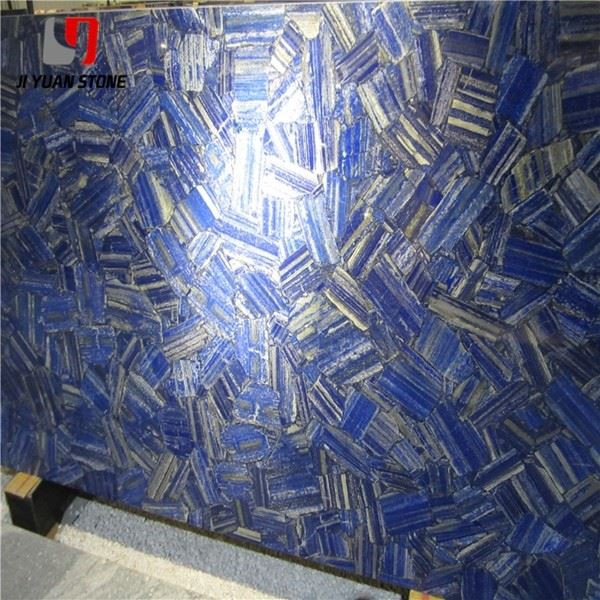

Sodalite Marble Tile

Sodalite Marble Tile

Sodalite Marble Tile – Strength Meets Sophistication in High-End Spaces

Transform your space with our Sodalite Marble Tile. Made from high-quality sodalite, this tile combines natural beauty with durability. Elevate any room with its elegant deep blue color and unique patterns. Experience the benefits of a luxurious and long-lasting flooring option.

| Feature | Details |

|---|---|

| Product Name | Sodalite Marble Tile |

| Material | 100% Sodalite Agate Gemstone |

| Surface Finished | Honed,Polished |

| Finished Products | Floor Tiles, Wall Cladding, Countertops, Windowsills, Special-Shaped Tiles, Small Slabs, Swimming Pool, Steps, Wall Panel, Flooring, Veneers, Slabs, Coping Tiles etc. |

| Color | Yellow,Black,White,Red,Purple Wood,Green,Grey,Pink,Rainbow,Pink,Tiger Eye etc |

| Size | Any sizes customized are welcome |

| Edge Available | Polished, Bush Hammer, Flat, Flamed, Eased, Beveled, Bullnose, Ogee, Cove, Dupont, laminated, non-laminated and etc. |

| Thickness | 10/15/18/20/25/30mm etc |

| Usage | Indoor/Outdoor Decoration, For floor or wall, Counter tops, Vanity tops |

| Packing | Seaworthy Wooden Crate |

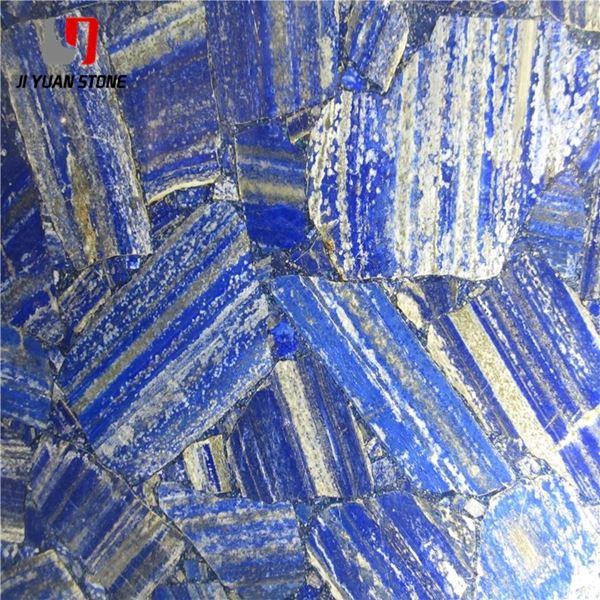

Sodalite marble tile is a stunning choice for premium interior design, known for its vibrant blue hues, unique veining, and rich texture. Ideal for walls, floors, and artistic inlays, these tiles bring a luxurious and timeless character to modern architecture. However, ensuring the long-term performance of sodalite marble requires not just visual appeal but also structural reinforcement.

🔷 The Importance of Reinforcement in Sodalite Marble Tile

The durability of sodalite marble tile, especially when used in high-end residential or commercial spaces, hinges on professional handling and reinforcement during fabrication. A notable case highlights this critical need:

In a luxury residential project decorated with Yunduola ash sodalite marble tile, a lack of reinforcement during fabrication led to severe breakage during transportation and installation. Since the client (Party A) did not initially require reinforcement due to budget constraints, the factory skipped this crucial step. As a result, the construction team faced significant delays and was unable to proceed due to extensive tile damage.

🔷 Reinforcement vs. Repair: A Cost Comparison

The incident analysis revealed that poor glue quality and rushed repairs during factory processing caused the damage. If high-quality structural glue had been used for proper pre-reinforcement, the tiles would have remained intact during transit. Alternatively, inserting reinforcing steel bars, particularly stainless steel, could have prevented the breakage altogether.

In one instance, a single sodalite marble slab was reinforced with 3 steel bars, each over 4 meters long. The cost of using stainless steel reinforcement was high—around 10 yuan/meter for regular steel and even more for stainless steel—raising the total cost per slab by at least 40 yuan. Meanwhile, using premium glue for pre-repair would have cost less than 20 yuan per slab.

Ultimately, due to the lack of initial reinforcement, the client incurred over 400,000 yuan in additional expenses—excluding labor and material replacement costs due to breakage during installation.

🔷 Why Choose Our Sodalite Marble Tile?

- ✅ Reinforced for Strength – We use proven reinforcement techniques, including proper glue repair and stainless steel support, to ensure long-term durability.

- ✅ Visual Excellence – Each tile is precision-cut, preserving the natural elegance and distinct veining of sodalite marble.

- ✅ Cost-Efficient Quality – By investing in smart reinforcement during production, we help reduce breakage, waste, and hidden costs during construction.

- ✅ Custom Solutions – Whether you need enhanced reinforcement or a premium finish for high-traffic areas, we tailor every order to your specifications.

🔷 Applications of Sodalite Marble Tile

- High-end residential flooring and walls

- Hotel and office lobbies

- Feature walls and staircase risers

- Designer bathrooms and kitchens

- Artistic or mosaic tilework

✅ Invest in Quality. Reinforce for Longevity.

Don’t compromise on quality when it comes to sodalite marble tile. Choose tiles that are not only beautiful but also structurally sound. Whether through reinforced glue repair or steel integration, our tiles are crafted to meet the demands of luxury architecture without risking unexpected costs.

Share