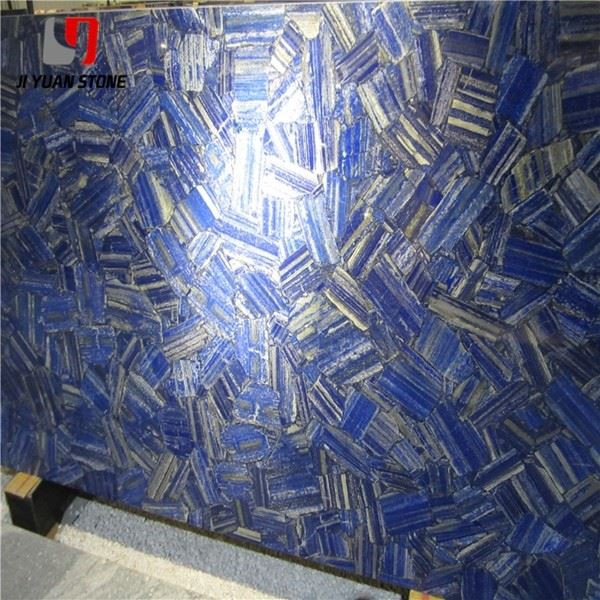

Sodalite Marble Slab

Sodalite Marble Slab

Sodalite Marble Slab – Engineered for Beauty, Strength, and Long-Term Value

Crafted from genuine Sodalite, our marble slab features stunning blue and white swirls that add elegance to any space. 100% natural and durable, this slab is perfect for countertops, backsplashes, and more. Upgrade your home with the unique beauty of Sodalite Marble.

| Feature | Details |

|---|---|

| Product Name | Sodalite Marble Slab |

| Material | 100% Sodalite Agate Gemstone |

| Surface Finished | Honed,Polished |

| Finished Products | Floor Tiles, Wall Cladding, Countertops, Windowsills, Special-Shaped Tiles, Small Slabs, Swimming Pool, Steps, Wall Panel, Flooring, Veneers, Slabs, Coping Tiles etc. |

| Color | Yellow,Black,White,Red,Purple Wood,Green,Grey,Pink,Rainbow,Pink,Tiger Eye etc |

| Size | Any sizes customized are welcome |

| Edge Available | Polished, Bush Hammer, Flat, Flamed, Eased, Beveled, Bullnose, Ogee, Cove, Dupont, laminated, non-laminated and etc. |

| Thickness | 10/15/18/20/25/30mm etc |

| Usage | Indoor/Outdoor Decoration, For floor or wall, Counter tops, Vanity tops |

| Packing | Seaworthy Wooden Crate |

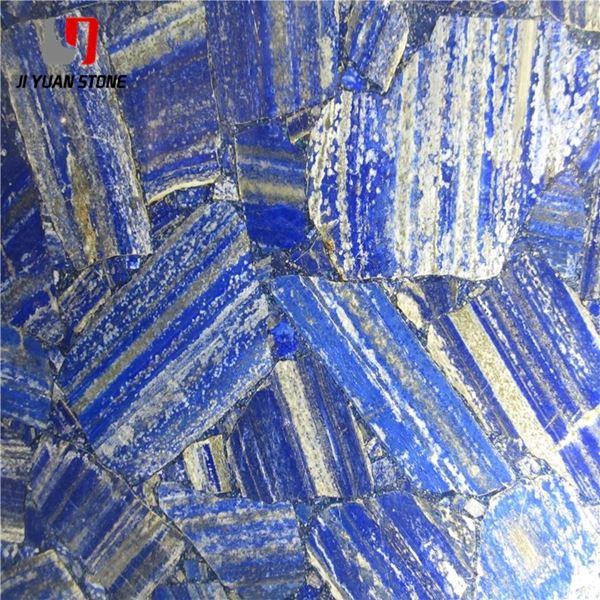

Sodalite marble slab is celebrated for its vibrant blue hues, deep veining, and luxurious appearance, making it a prime choice for interior designers, architects, and builders. However, the performance and reputation of this stone rest heavily on the quality of slab preparation—particularly crack detection and repair.

🔷 Why Crack Repair in Sodalite Marble Slabs Matters

One of the most persistent challenges facing natural marble—especially sodalite—is cracking. If left unrepaired, cracks:

- Compromise the structural integrity of the slab

- Damage the aesthetic appeal, making the surface less attractive

- Lower production yield, leading to waste and higher costs

- Cause customer dissatisfaction, often resulting in complaints or disputes

- Hurt the reputation and profitability of marble processing enterprises

The consequences of poor crack management extend beyond aesthetics. If the sodalite marble slab cracks during installation or use, it not only jeopardizes the success of the project but also leads to costly returns, reduced client trust, and potential legal or reputational issues.

🔷 Real-World Example: When Crack Neglect Becomes Expensive

In a recent project, a large volume of sodalite marble slabs was ultimately rejected by the client. The problem? Cracks that had not been properly repaired. Although kraft paper was temporarily applied to reinforce the slabs, the damage had already been done. One look at the boards showed a surface filled with dense, net-like cracks, resembling a broken fishing net—completely unacceptable for high-end applications.

This incident underscores how improper repair or no repair at all during the production stage can lead to excessive waste, increased costs, and even complete project failure.

🔷 What We Do Differently

At Purchase Stones, our sodalite marble slabs are reinforced using advanced crack-repair techniques and high-performance adhesives that restore both the strength and visual quality of the stone. Here's how we ensure top-tier quality:

- ✅ Thorough Crack Inspection Before shipment, every slab undergoes careful inspection for surface and internal cracks.

- ✅ Expert Glue Repairs Using high-quality adhesives designed specifically for marble, we seal cracks to restore slab strength and beauty.

- ✅ No Temporary Fixes We don’t rely on kraft paper band-aids. Our slabs are structurally sound, polished, and ready for installation.

- ✅ Low Waste, High Yield Our method improves the yield per block, ensuring cost-effective, sustainable production.

🔷 Ideal Uses for Sodalite Marble Slab:

- Hotel and office feature walls

- Residential and commercial flooring

- Countertops and kitchen islands

- Stair treads and risers

- High-end bathroom vanities and wall cladding

✅ Why Choose Our Sodalite Marble Slab?

- 🌟 Crack-Free Finish – Professionally repaired and reinforced for long-lasting performance

- 🌟 Visual Impact – Deep, elegant blue veining ideal for luxury applications

- 🌟 Reliable Quality – Every slab is hand-selected and quality-checked before shipping

- 🌟 Sustainable Production – Lower waste and better yield through effective crack repair

🔷 Final Word: Protect Your Investment, Preserve Your Reputation

Cracked sodalite marble slabs don’t just reduce material value—they risk your entire project and brand. With our expertly prepared slabs, you get stone that’s not only visually stunning but also built to last.

Choose quality. Choose sustainability. Choose Purchase Stones.

Share