Slate Stone Wall Stone

Slate Stone Wall Stone

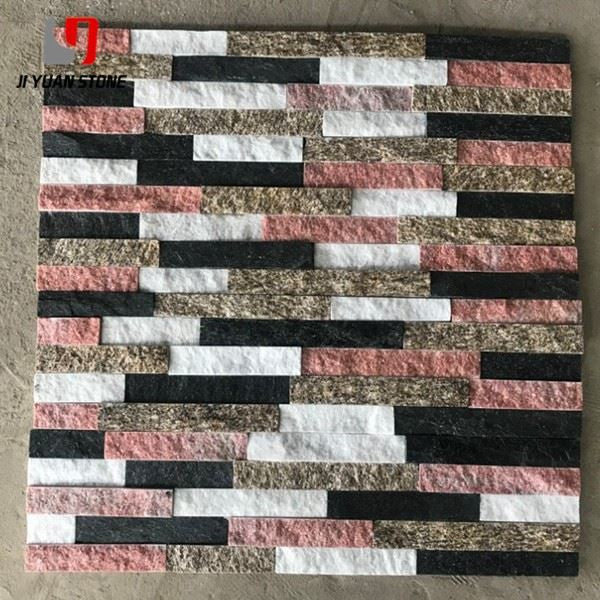

Slate Stone Wall Stone – Premium Natural Panels for Timeless Wall Designs

Upgrade your home or business with our Slate Stone Wall Stone. Experience a timeless and elegant look with this durable material. Made from high-quality slate, this versatile product adds a touch of sophistication to any interior or exterior design. Elevate your space with Slate Stone Wall Stone.

| Feature | Details |

|---|---|

| Product | Slate Stone Wall Stone |

| Surface | Split face |

| Thickness | 0.8-1.2cm,1-1.5cm,1-2cm,1.5-2.5cm,2.5-3.5cm etc |

| Finished Products | Floor tiles, Wall cladding, Countertops, Windowsills, Special-shaped tiles, Small slabs, Swimming pool, stairs, steps, wall panel, flooring, veneers, slabs, coping tiles, bathtub etc |

| Colour | Black, Blue, White, Red, Pink, Brown, Yellow, Grey, Green, Purple, etc. |

| Material | Granite, Marble, Quartz, Sandstone, Basalt, Slate, Travertine etc |

| Products | Available in Slabs, Tiles, and customized sizes.ect |

| Application | Outdoor and indoor construction projects; |

| Sizes | Available in different sizes for different products; Customized specification is also available. |

| Thickness (cm) | 1, 1.2, 1.5, 1.8, 2, 3, etc |

| Slabs (cm) | 60x120up, 70x120up,120upx240up,etc |

| Tiles (cm) | 30x30,60x60,30x60,305x305,etc |

| Edge | Bevel, Flat, Bullnose, Cut, etc |

| Finish | Polished, Honed, Flamed, Bushhammered, etc |

| Package | International Seaworthy wooden crates; available with Customized packing requirements |

Transform your space with the bold elegance of Slate Stone Wall Stone, a top-tier natural slate solution designed for both indoor and outdoor wall cladding. These stone panels are perfect for accent walls, building facades, fireplace surrounds, garden walls, and more. Their naturally split textures and timeless colors make them a favorite among architects, designers, and homeowners alike.

Crafted from high-quality slate, these wall stones are built to withstand the elements while delivering a visually stunning aesthetic to any structure. Whether you're planning an interior upgrade or designing a durable exterior facade, our slate wall stones offer beauty and performance that last.

🛠 Slate Stone Wall Stone Installation Guide

Proper installation is critical to ensuring the longevity and safety of slate wall stone panels. Below is a professional guide for best practices:

1. Fixing the Slate Hanging Board

- The slate panel is attached to the wall using double-strand 18# copper wire or a wire hook.

- The wall surface should be grooved using a hand-held cutting machine (vertical cut or at a 45° angle).

- Insert steel nails into the grooves for support.

- If a panel’s vertical length exceeds 300mm, use at least two hanging points for secure anchoring.

2. Reinforcement for Structural Openings

- For areas around doors, windows, or ceilings, use aluminum sheets or flat iron side reinforcements to ensure stability and durability.

3. Grooving for Gelatin Applications

- If the wall design includes gelatin application, open triangular slots or small grooves at the panel joints to facilitate proper adhesion.

4. Preparing for Cement Mortar Grouting

- Pre-wet the wall before applying cement mortar to improve bond strength.

- Use a cement-to-sand ratio no less than 1:3 for adequate strength and workability.

- Ensure the mortar has good fluidity for even distribution.

5. Cement Mortar Pouring Method

- Pour the cement mortar at a 45-degree angle to fill all cavities thoroughly.

- Avoid using semi-dry mortar for top panels and pressure-bearing parts; always use flowing mortar for a proper finish.

6. Seam and Joint Guidelines

- Glue seam width should follow the design specifications.

- Ensure all glue lines are uniform and burr-free, maintaining a clean and professional finish.

7. Insulation Consideration

- If external insulation is required, avoid using wet grouting methods for slate wall stone installation.

🌟 Key Features

- ✅ Natural Slate Material – Rich, earthy textures and color tones

- ✅ Weather-Resistant & Long-Lasting – Ideal for exterior installations

- ✅ Versatile Applications – Suitable for residential, commercial, and landscaping uses

- ✅ Professional Installation Flexibility – Compatible with both mechanical hanging and cement mortar methods

🧱 Applications

- Building facades

- Interior feature walls

- Fireplace surrounds

- Outdoor landscape walls

- Entrance columns and more

📐 Product Specifications

- Material: Natural Slate

- Thickness Options: Varies by design

- Finish: Natural split surface

- Color: Available in multiple natural slate hues

- Installation: Hanging system or cement mortar as per site requirements

🧼 Maintenance Tips

- Use neutral pH cleaners to maintain color and texture.

- Periodically check for loose joints or mortar damage.

- Reapply sealant as needed based on exposure and wear.

Create enduring architecture with the rustic charm of Slate Stone Wall Stone. Designed for aesthetic beauty and structural integrity, it’s the perfect choice for timeless walls that stand the test of time.

Share