Slate Stone Tile

Slate Stone Tile

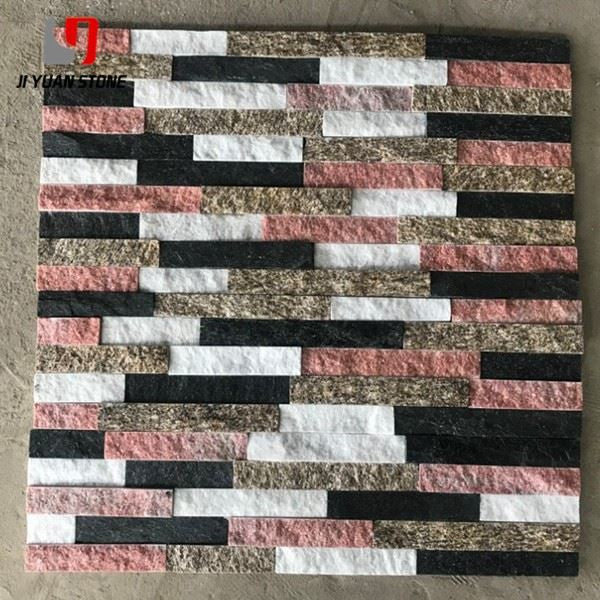

Slate Stone Tile – Durable, Stylish & Engineered for Long-Lasting Wall Applications

Slate Stone Tile is a durable and versatile option for your flooring needs. Made from natural slate stone, it offers a unique and elegant look to any room. With its sturdy properties, it is resistant to moisture and scratches, making it perfect for high-traffic areas. Transform your space with the timeless beauty of Slate Stone Tile.

| Feature | Details |

|---|---|

| Product | Slate Stone Tile |

| Surface | Split face |

| Thickness | 0.8-1.2cm,1-1.5cm,1-2cm,1.5-2.5cm,2.5-3.5cm etc |

| Finished Products | Floor tiles, Wall cladding, Countertops, Windowsills, Special-shaped tiles, Small slabs, Swimming pool, stairs, steps, wall panel, flooring, veneers, slabs, coping tiles, bathtub etc |

| Colour | Black, Blue, White, Red, Pink, Brown, Yellow, Grey, Green, Purple, etc. |

| Material | Granite, Marble, Quartz, Sandstone, Basalt, Slate, Travertine etc |

| Products | Available in Slabs, Tiles, and customized sizes.ect |

| Application | Outdoor and indoor construction projects; |

| Sizes | Available in different sizes for different products; Customized specification is also available. |

| Thickness (cm) | 1, 1.2, 1.5, 1.8, 2, 3, etc |

| Slabs (cm) | 60x120up, 70x120up,120upx240up,etc |

| Tiles (cm) | 30x30,60x60,30x60,305x305,etc |

| Edge | Bevel, Flat, Bullnose, Cut, etc |

| Finish | Polished, Honed, Flamed, Bushhammered, etc |

| Package | International Seaworthy wooden crates; available with Customized packing requirements |

Slate stone tile is a natural and versatile material widely used in wall cladding and interior or exterior décor. Its distinct textures, natural colors, and structural integrity make it ideal for premium design projects. Whether you're enhancing a living space, feature wall, or exterior facade, slate stone tile offers timeless charm and durability.

However, achieving a professional, lasting result requires proper installation techniques and careful handling of adhesives and surface protection. Below, we explore common dry hanging glue issues, their solutions, and expert installation methods to help you make informed decisions for your project.

🧪 Slate Stone Tile Dry Hanging Glue Pollution & Control Measures

Common Issues with Dry Hanging Glue Pollution:

- Insufficient Stone Thickness – Thin stones can lead to weak slotting and structural instability.

- Lack of Protective Agent – Not reapplying sealants after grooving exposes the stone to contaminants.

- Poor Glue Quality or Incorrect Mixing – Low-grade adhesives or wrong proportions can delay curing or cause surface damage.

- Uneven Mixing of Glue – Results in separation, oiling-out, or failure to bond properly.

✅ Control Measures:

- Ensure Proper Stone Thickness – Use thickness based on stone type and application needs.

- Reapply Protective Agent – After grooving, clean the area and apply the same protective sealer.

- Use High-Quality Epoxy Resin AB Glue – Ensures a strong and reliable bond for dry hanging.

- Follow Exact Mixing Ratios – Typically 1:1 for two-component adhesives. Stir thoroughly to activate.

- Clean Glue Penetration – Remove excess glue using a professional stone degreasing/degumming agent.

🧱 Slate Stone Tile Installation Methods:

Slate tiles can be installed using four standard methods:

- Dry Hanging

- Wet Pasting

- Wet Hanging

- Dry Pasting

Each method is selected based on project requirements, stone thickness, location, and finish expectations.

🔧 Wall Stone Point Bonding Construction Process

For robust and aesthetically pleasing installations, follow this proven point-bonding method:

1 . Grooving – Use an electric cutting machine to groove both the wall and back of the slate tile (no keels required).

2 . Steel Spacer Insertion – Insert a steel gasket (e.g., 40 × 40 × 3 mm or 30 × 30 × 2 mm) for alignment and load bearing.

3 . Apply Structural Glue – Use a two-component epoxy dry-hanging AB structural adhesive in grooves. Add silicone structural adhesive to reinforce.

4 . Determine Glue Points – Glue point count depends on tile size.

- Example: For Caesar Gray Marble (1,475 mm × 450 mm × 18 mm), use 2 steel spacers and 6 glue points.

5 . Final Installation – Maintain a 10–30 mm clearance between the stone and wall for proper ventilation and secure fitting.

🌟 Key Benefits of Slate Stone Tile:

- High Durability & Strength – Perfect for walls, both interior and exterior.

- Natural Textures – Adds rustic, contemporary, or modern elegance.

- Flexible Installation Methods – Adaptable to dry or wet hanging/pasting.

- Glue Pollution Prevention – Professional guidance minimizes risks of adhesive staining or failure.

- Enhanced Protection – Compatible with sealing agents for long-term beauty and hygiene.

🏠 Ideal Applications:

- Interior Feature Walls

- Building Facades

- Commercial Spaces

- Luxury Bathrooms & Kitchens

- Garden and Landscape Walls

Conclusion:

Slate stone tile not only elevates the aesthetic appeal of your project but also ensures structural performance when installed correctly. By addressing glue pollution issues and following best practices for installation, you can achieve long-lasting beauty and integrity in every detail.

👉 Ready to start your project? Order your premium slate stone tiles now and ensure flawless results with expert installation techniques!

Share