Slate Roofing Tiles

Slate Roofing Tiles

Slate Roofing Tiles – Large-Diameter Arc Cylinder Dry-Hanging System

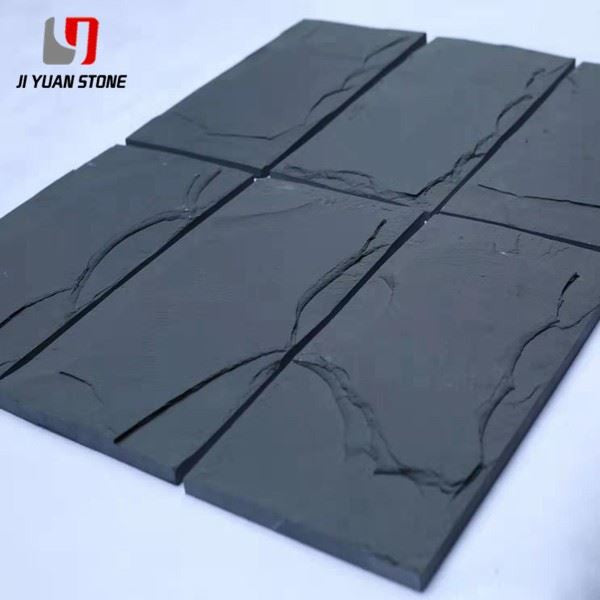

Crafted from natural slate, these roofing tiles provide superior durability and waterproofing for your home. With a lifespan of over 100 years, they are a long-term investment in your home's protection. Create a timeless and elegant look with these high-quality, expertly crafted roofing tiles.

| Feature | Details |

|---|---|

| Product | Slate roofing tiles |

| Surface | Honed, Split,natural,Machine Cut, etc |

| Colour | Black |

| Finished Products | Roof Tile etc |

| Size |

|

| Thickness | 04-8mm etc |

| Packing | Carton,wooden crate,wooden pallet |

| Packing way |

|

Enhance your architectural projects with our premium slate roofing tiles, designed for large-diameter arc cylinder dry-hanging systems. This advanced method is ideal for curved stone curtain walls and hyperboloid roofing tile applications, offering superior performance, precision, and aesthetic appeal.

🔧 Key Operations for Large-Diameter Arc Cylinder Dry-Hanging Slate Roofing Tiles

The installation of large-diameter arc cylinder dry-hanging slate roofing tiles involves a series of critical technical steps, including:

- Fixed-length welding

- Arc steel mold creation

- Arc keel reinforcement

- Solid cylinder arc control

For diameters between 1500mm and 5000mm, a custom mold is created on-site using light steel keel frameworks. This flexible solution eliminates the need for transporting complex components, significantly reducing deformation risks and construction costs.

🏗️ Key Construction Process

1. Mold and Platform Production

- A 400mm × 3000mm × 3000mm concrete operation platform is constructed.

- A 2000mm long arc mold is fixed onto the platform to shape the curved slate tiles.

2. Curved Arc Formation for Light Steel Keel

- A 50mm × 50mm angle steel is bent at 150mm intervals to form the initial arc.

- The preliminary arc is placed into the mold for further shaping, correction, and reinforcement.

✅ Advantages Over Conventional Construction Methods

This modern construction method offers several key benefits:

- ✅ Widely Available Materials: Reduces sourcing and procurement costs.

- ✅ On-Site Fabrication: Avoids transportation errors, boosts precision.

- ✅ Reduced Complexity: Minimizes the need for adjusting special-shaped components.

- ✅ Faster Turnaround: Streamlines production and shortens construction timelines.

🧰 Main Features of Slate Roofing Tiles Installation

✔ Clear Process Flow – Simplifies training and implementation.

✔ Optimized Arc Keel Production – Prevents deformation during transport.

✔ Cost & Energy Efficiency – Lowers operational expenses.

✔ Standardized Production – Enhances consistency and minimizes waste.

✔ Flexible Application – Ideal for various architectural designs and construction needs.

This refined and professional process for slate roofing tile installation ensures a balance between durability, aesthetics, and cost-efficiency. Whether you're working on a curved stone curtain wall or a complex roofing tile façade, our solution delivers high-quality results with minimal hassle.

Share