Semi Precious Stone Slabs

Semi Precious Stone Slabs

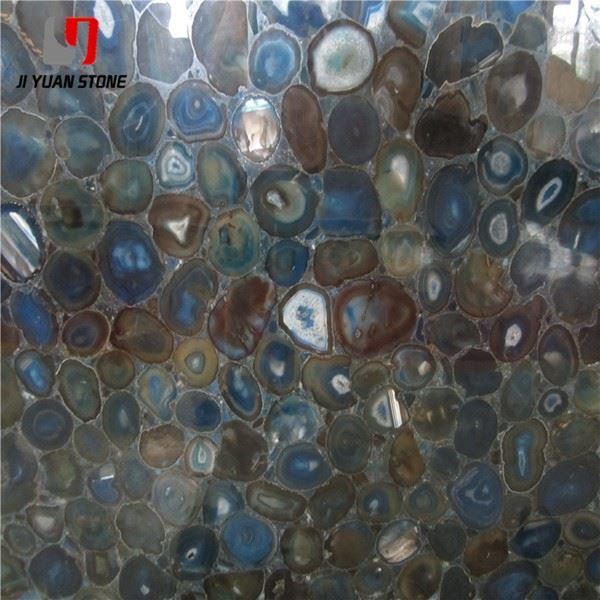

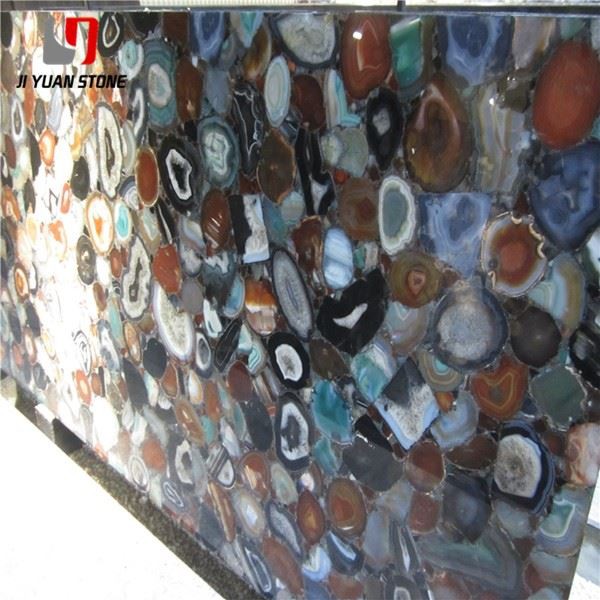

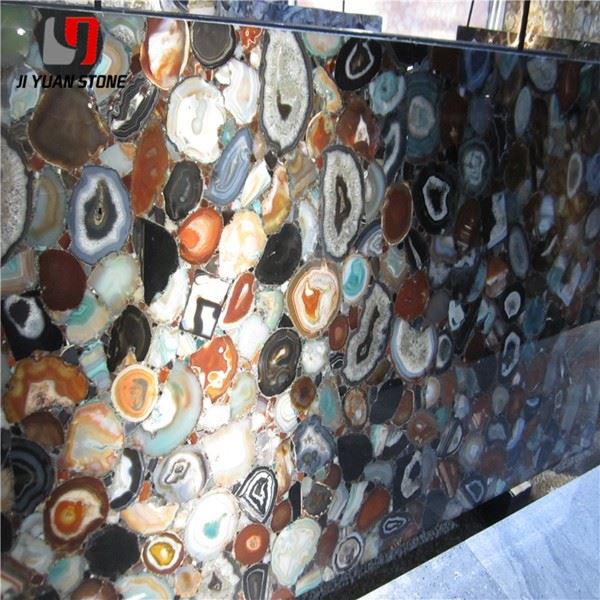

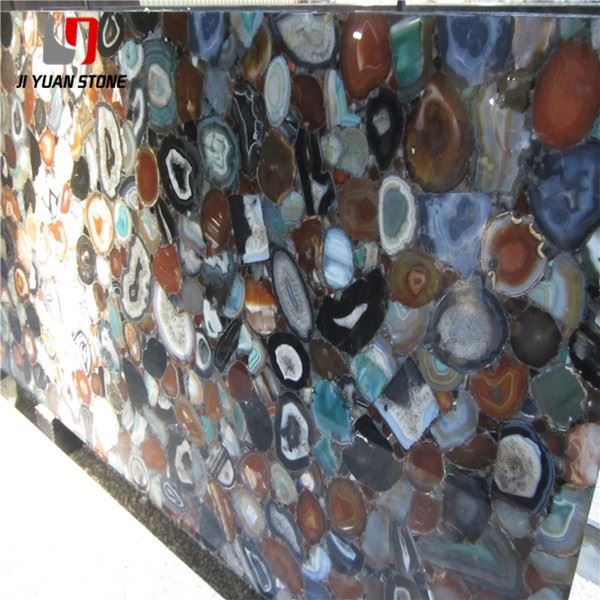

Semi-Precious Stone Slabs – Beauty and Durability for Timeless Interiors

Experience the timeless beauty and durability of our Semi Precious Stone Slabs. These slabs are crafted with precision and expert craftsmanship, showcasing the natural colors and patterns of semi precious stones. Perfect for adding a touch of elegance to any space, these slabs offer long-lasting quality and a unique, sophisticated look.

| Feature | Details |

|---|---|

| Product Name | Semi Precious stone slabs |

| Material | Agate Gemstone Semi-precious Stone |

| Surface Finished | Honed,Polished |

| Finished Products | Floor Tiles, Wall Cladding, Countertops, Windowsills, Special-Shaped Tiles, Small Slabs, Swimming Pool, Steps, Wall Panel, Flooring, Veneers, Slabs, Coping Tiles etc. |

| Color | Yellow,Black,White,Red,Purple Wood,Green,Grey,Pink,Rainbow,Pink,Tiger Eye etc |

| Slab Size |

|

| Tile Size |

|

| Package Detail |

1) Slab: plastic inside + strong seaworthy wooden bundle outside 2) tile: foam inside + strong seaworthy wooden crates with reinforced straps outside 3) Countertop: foam inside + strong seaworthy wooden crates with reinforced straps outside |

Bring unmatched sophistication and lasting strength to your interior spaces with our semi-precious stone slabs. Composed of vibrant, natural stones like turquoise, malachite, howlite, and more, these slabs offer a luxurious, exotic aesthetic that elevates any room—from residential living areas to upscale commercial environments.

Whether used for walls, countertops, or flooring, semi-precious stone slabs captivate with their rich natural colors and intricate, eye-catching patterns. But these slabs are not just about beauty—they are also built to withstand daily wear, making them a top choice for high-traffic areas.

🌟 Key Features:

- Crafted from premium semi-precious stones

- Striking patterns and bold natural colors

- Suitable for floors, feature walls, and countertops

- High durability for long-lasting performance

- Perfect for luxury residential and commercial designs

🔧 Precautions for Installation:

To maintain both the aesthetic and structural integrity of your semi-precious stone slabs, follow these essential precautions during installation:

- Water Quality: Use only clean water (such as clear tap water) when preparing the binder.

- No Additives: Do not introduce any additives during adhesive preparation.

- Usage Time: Apply the adjusted slurry within 2 hours to maintain effectiveness.

- Surface Treatment: Avoid using standard protective agents on the bonding surface before application. Instead, use AD2009 waterproof adhesive, which prevents issues like water stains, white marks, and potential detachment.

🛠️ Dry Hanging Installation Method:

A common and recommended installation technique for these slabs is the dry hanging method, especially for vertical applications.

2.1 Slot Type (Seam Type) Dry Hanging Method:

- Process: A through slot or semi-circular groove is created on the upper and lower edges of the slab. A T-shaped plate is inserted into the grooves, and the stone is secured by injecting adhesive into the slot.

⚠️ Disadvantages of Slot Type Dry Hanging:

- The upper and lower slabs are interdependent, reducing individual flexibility.

- Vibrations may cause squeezing or damage to the stone or hook plates.

- The structure has low shockproof performance and limited tolerance to deformation or displacement.

Despite these drawbacks, when installed correctly and with proper precautions, semi-precious stone slabs offer exceptional elegance, resilience, and a one-of-a-kind look that enhances any space.

Transform your space with the timeless elegance and powerful presence of semi-precious stone slabs. When beauty meets strength, design becomes truly extraordinary.

Share