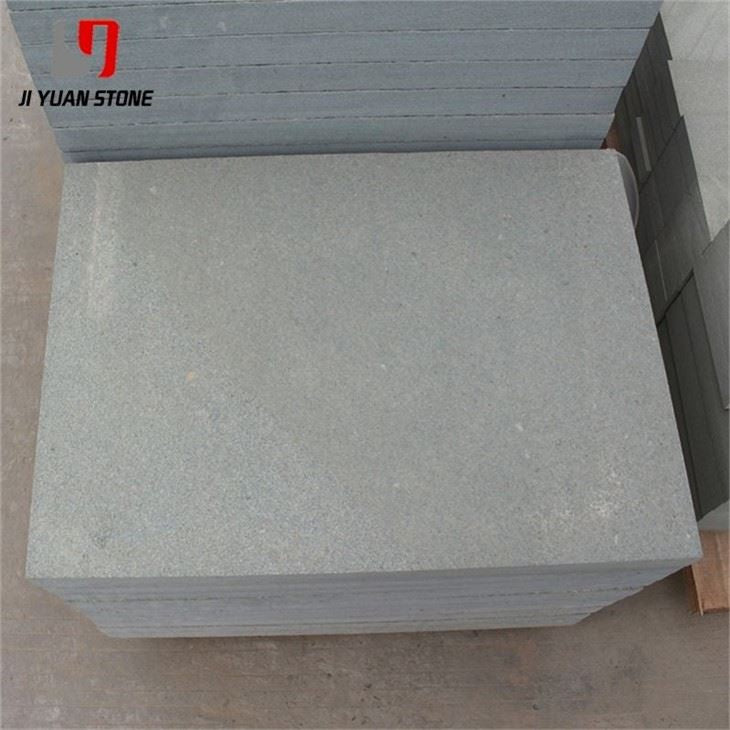

Sandstone Wall Stone

Sandstone Wall Stone

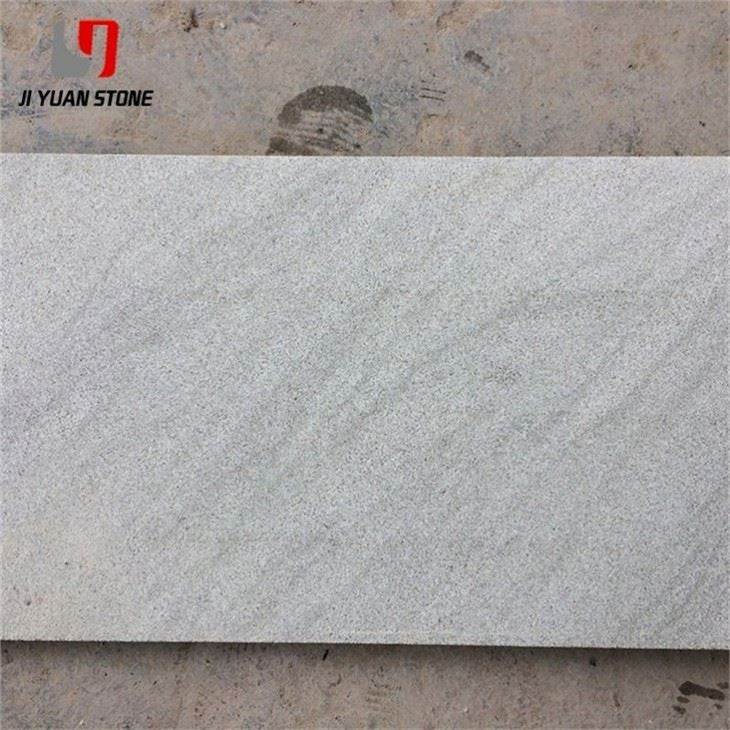

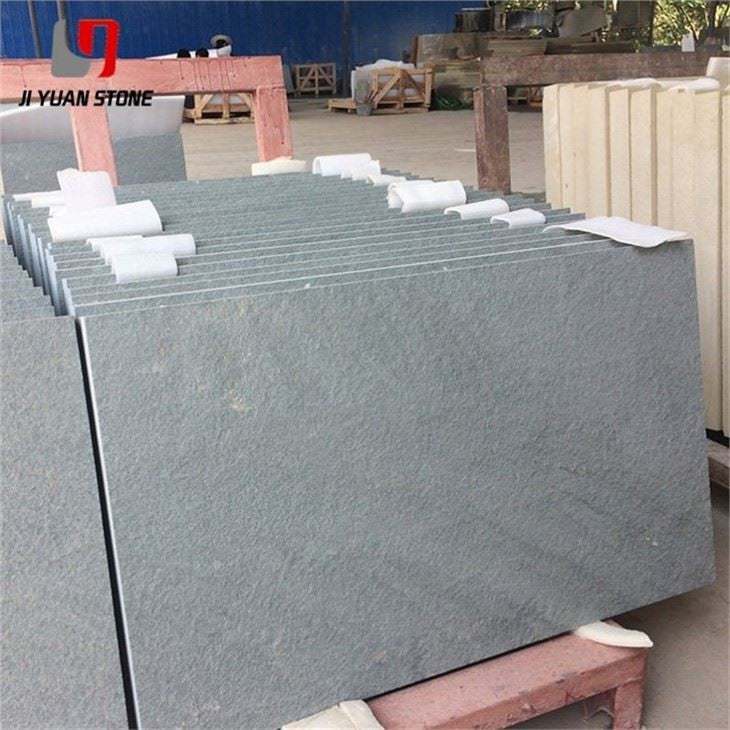

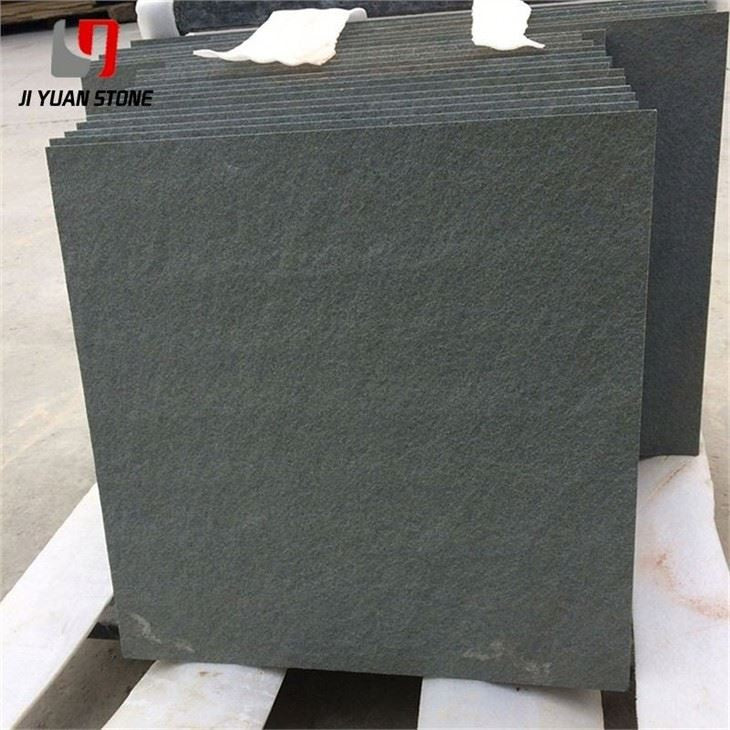

Made from high-quality sandstone, this wall stone is perfect for adding a natural and elegant touch to any space. Its durability and unique color variations make it a versatile choice for indoor or outdoor use. With easy installation and low maintenance, it's sure to be a long-lasting and attractive addition to your home.

| Feature | Details |

|---|---|

| Materia | Natural Sandstone |

| Surface Finished | Honed,Flamed,Bush-hammered,Brushed,Nature,Mushroom,Sawn etc |

| Finished Products | Floor tiles, Wall cladding, Countertops, Windowsills, Special-shaped tiles, Small slabs, Swimming pool, steps, wall panel, flooring, veneers, slabs, coping tiles, etc |

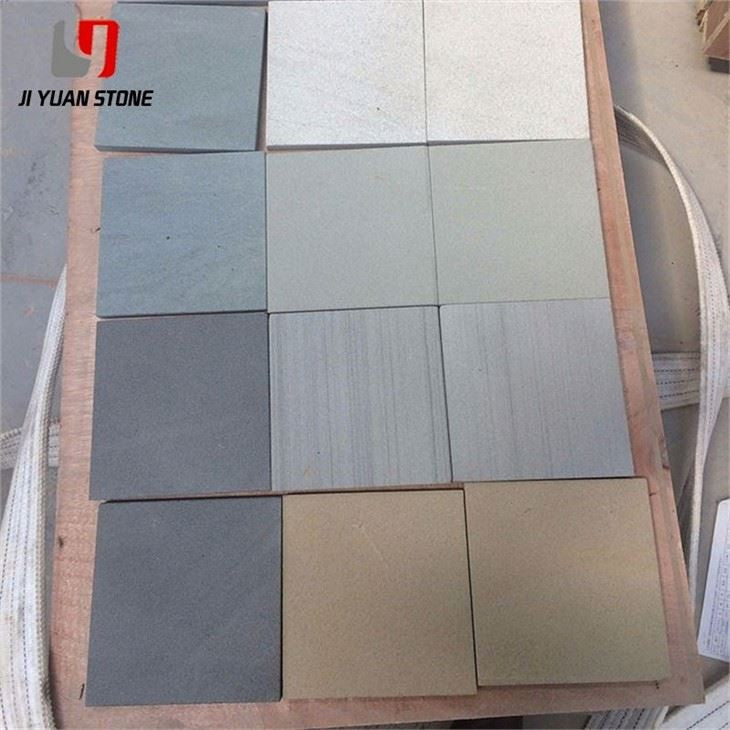

| Color | Yellow,black,white,red,purple wood,green,grey,rainbow etc |

| Size | Customized Pls contact us for the newest catalog of sandstone |

10 years + Experience In The Natural Stone Field;

2. Wide Ranges of Materials, Colors, Sizes, Thickness, Finish and Patterns For Your Options;

3. Top Quality with Competitive Price and Fast Delivery;4. Excellent & Professional Service from Ji Yuan Stone

Sandstone paving Tiles would add brightness and clarity to your garden or patio with its cream, golden to orange shades. These light-coloured tiles are very impressive, stable and reliable. We offer these sandstones in natural, honed and cobblestone types. The tiles have elegant look and would suit modern and traditional surroundings. Choose from various sizes, thickness and types. buff Sandstone Befitted to add a dash of grace with rustic and exotic designs that adds an ethereal touch to the ambiance. Likely characterized with leaf fossilization on the surface, Buff is ideal patio sandstone.

Handling Special Circumstances in Sandstone Wall Tile Installation

In construction, using unqualified sandstone wall tiles outdoors is not acceptable. However, in certain cases, due to unforeseen factors, sandstone wall tiles and travertine may be purchased and processed without a technical feasibility analysis. Sometimes, materials are transported to the site and even installed before realizing that they do not meet the basic quality standards.

Risks of Using Substandard Stone

- Installed or uninstalled slabs that fail to meet specifications pose significant risks.

- Common practice dictates that non-compliant slate should never be installed.

- Replacing defective slabs is the safest and most recommended solution.

Challenges of Replacing Non-Compliant Tiles

- Project constraints may make tile replacement challenging.

- Owners and project personnel may find it difficult to accept the additional costs and delays.

- External pressures can make removal and replacement an unrealistic option.

Alternative Solutions: Technical Evaluation & Safety Measures

If replacement is not feasible, strict technical assessments and special safety measures must be implemented.

- Ensure structural integrity through reinforcement techniques.

- Conduct extensive quality checks before proceeding with further installations.

- Accept increased engineering costs for added safety—safety is priceless.

While the best solution is to avoid using substandard materials, when circumstances do not allow replacement, a rigorous evaluation process and enhanced safety measures must be followed without hesitation.

Share