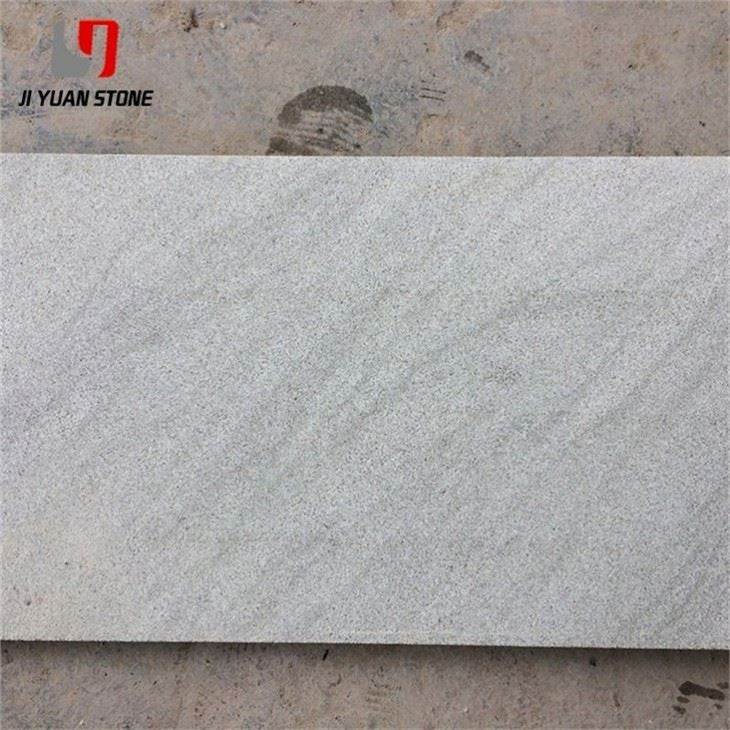

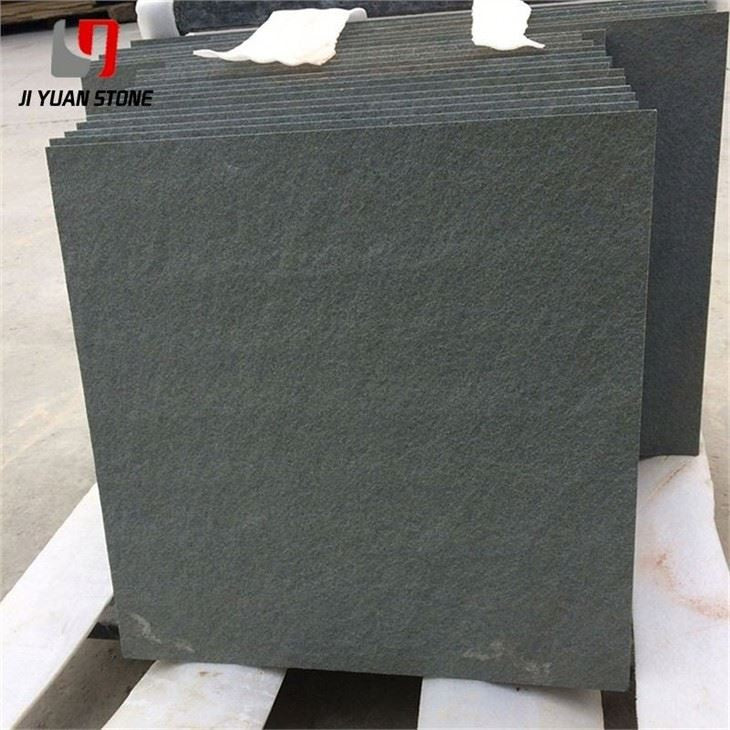

Sandstone Wall Stone

Sandstone Wall Stone

Expertly crafted from sandstone, our Sandstone Wall Stone is a durable and versatile choice for any wall project. Its natural texture and varying shades add aesthetic appeal, while its strength and longevity make it a practical and cost-effective option. Transform your space with this high-quality building material.

| Feature | Details |

|---|---|

| Materia | Natural Sandstone |

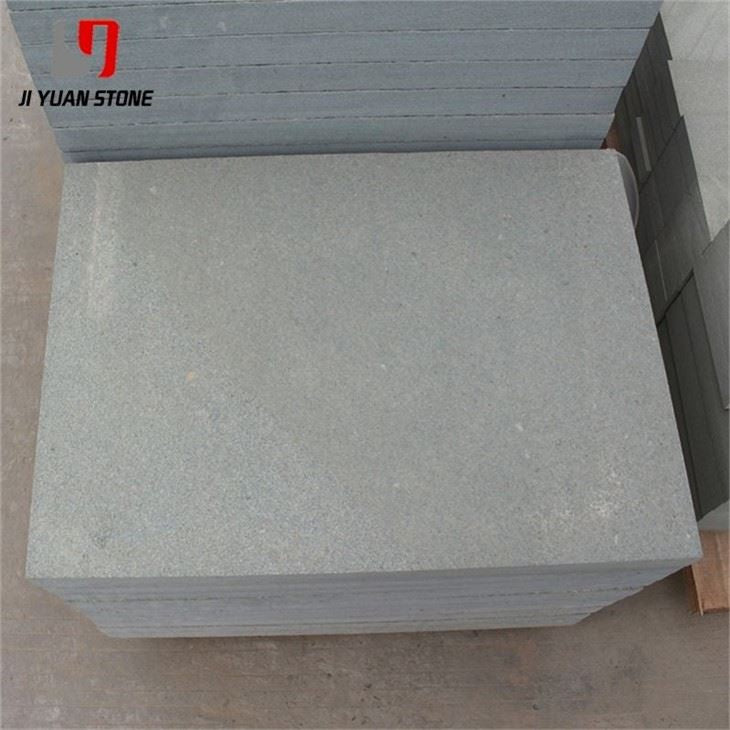

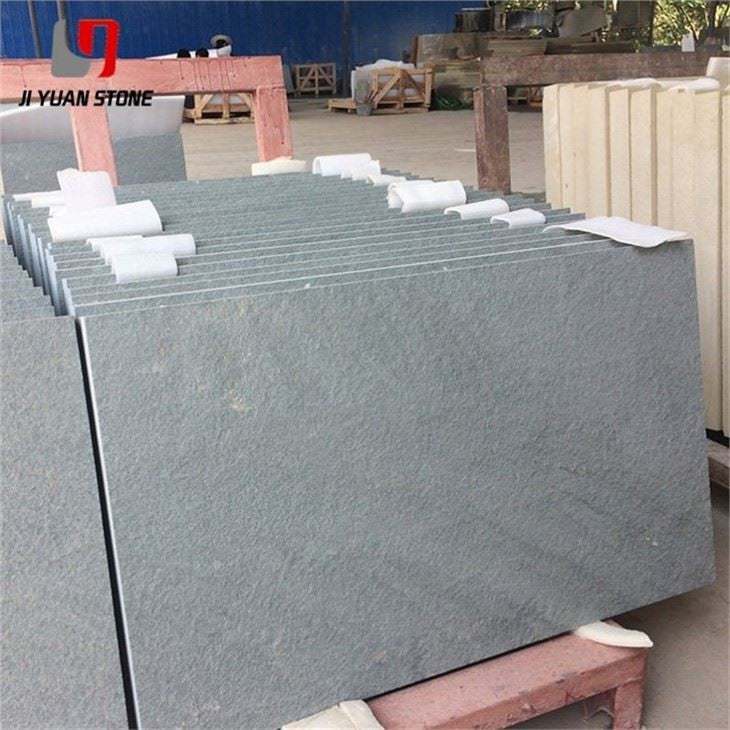

| Surface Finished | Honed,Flamed,Bush-hammered,Brushed,Nature,Mushroom,Sawn etc |

| Finished Products | Floor tiles, Wall cladding, Countertops, Windowsills, Special-shaped tiles, Small slabs, Swimming pool, steps, wall panel, flooring, veneers, slabs, coping tiles, etc |

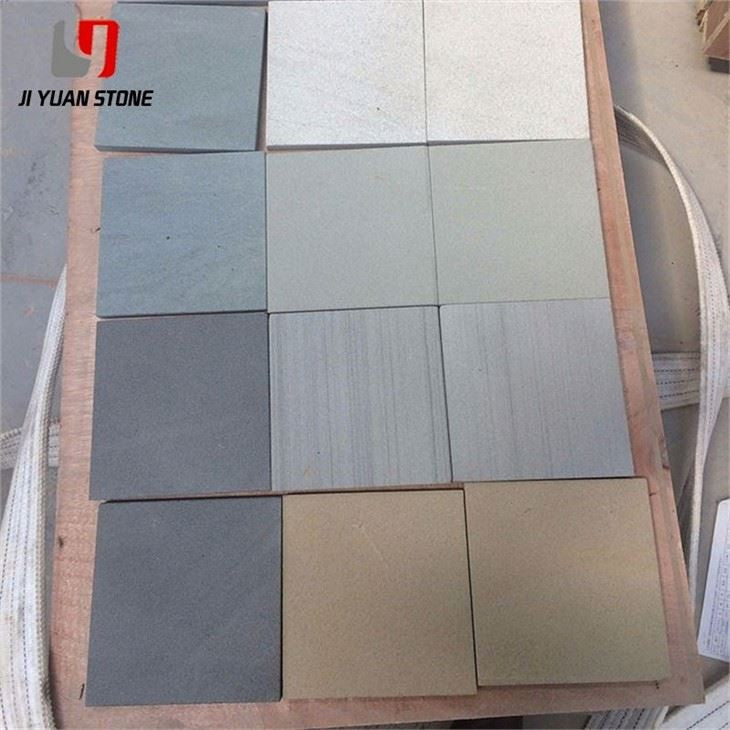

| Color | Yellow,black,white,red,purple wood,green,grey,rainbow etc |

| Size | Customized Pls contact us for the newest catalog of sandstone |

10 years + Experience In The Natural Stone Field;

2. Wide Ranges of Materials, Colors, Sizes, Thickness, Finish and Patterns For Your Options;

3. Top Quality with Competitive Price and Fast Delivery;4. Excellent & Professional Service from Ji Yuan Stone

Sandstone paving Tiles would add brightness and clarity to your garden or patio with its cream, golden to orange shades. These light-coloured tiles are very impressive, stable and reliable. We offer these sandstones in natural, honed and cobblestone types. The tiles have elegant look and would suit modern and traditional surroundings. Choose from various sizes, thickness and types. buff Sandstone Befitted to add a dash of grace with rustic and exotic designs that adds an ethereal touch to the ambiance. Likely characterized with leaf fossilization on the surface, Buff is ideal patio sandstone.

Surface Treatment for Sandstone Wall Stone

Waterproofing

- Sandstone wall stone and travertine have high water absorption, requiring waterproof coatings to reduce absorption rates to less than 1%.

-

Recommended waterproof coatings:

- Organic fluorine or organic silicon paint

- Must be breathable, non-film-forming, and should not alter the stone's gloss or color

- Reapplication is necessary, as waterproof coatings typically last no more than 5 years.

Application Based on Joint Type

- Glue-injected board seams → Waterproofing should be applied only on the outer surface.

- Open board seams → Waterproofing must be applied on all six sides of the stone slab.

Sealing & Final Treatment

- Travertine with large or excessive holes should be properly sealed.

- Waterproofing should be done after machining, cleaning, and drying all grooves and holes.

Back Composite Layer for Strength & Durability

- Sandstone and travertine have low strength, are brittle, and are not highly weather-resistant.

- To prevent breakage and potential hazards, a reinforcing composite layer (e.g., fiberglass cloth) should be applied to the back of the slabs.

This reinforcement ensures structural integrity, enhances durability, and prevents falling accidents due to stone breakage.

Share