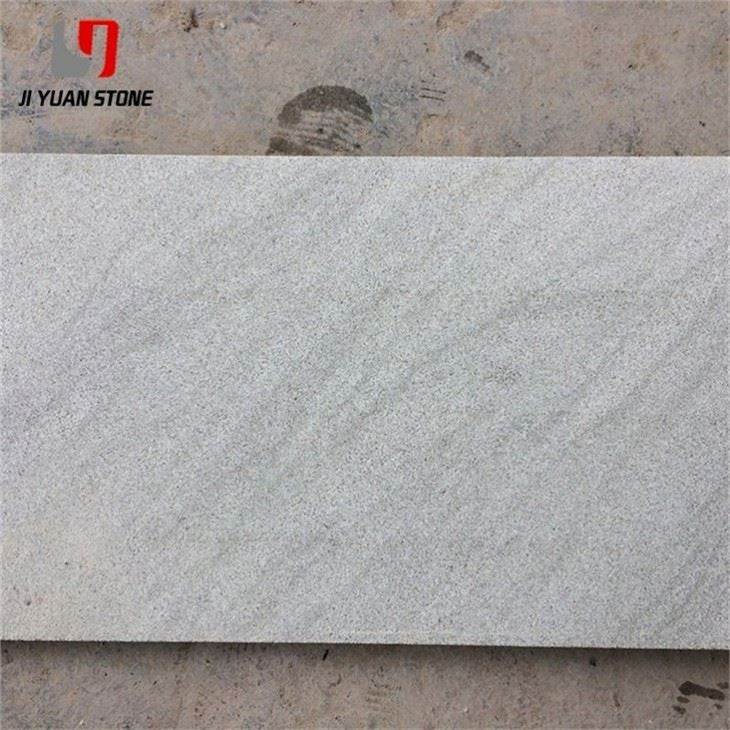

Sandstone Veneerstone

Sandstone Veneerstone

Experience the beauty and durability of our Sandstone Veneerstone. Made with high-quality sandstone, this veneer adds a touch of elegance to any space while providing long-lasting protection. Upgrade your home with this natural and versatile building material.

| Feature | Details |

|---|---|

| Materia | Natural Sandstone |

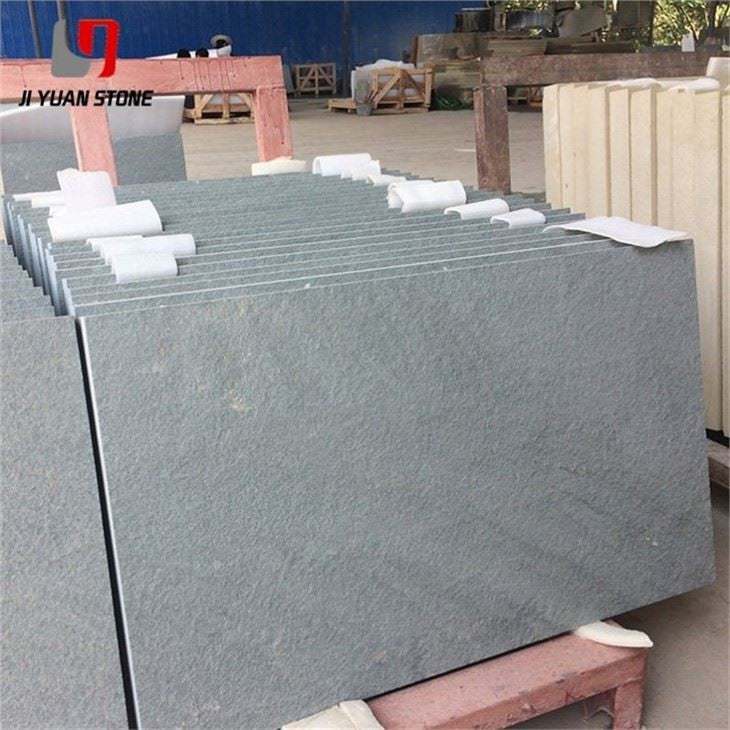

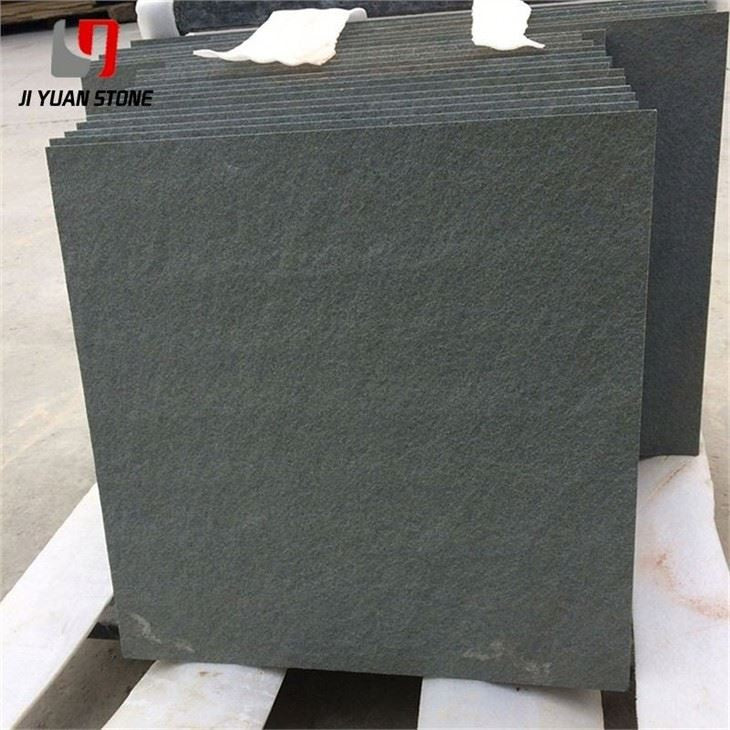

| Surface Finished | Honed,Flamed,Bush-hammered,Brushed,Nature,Mushroom,Sawn etc |

| Finished Products | Floor tiles, Wall cladding, Countertops, Windowsills, Special-shaped tiles, Small slabs, Swimming pool, steps, wall panel, flooring, veneers, slabs, coping tiles, etc |

| Color | Yellow,black,white,red,purple wood,green,grey,rainbow etc |

| Size | Customized Pls contact us for the newest catalog of sandstone |

All sandstone products are manufactured to the highest quality international standards in our state-of-the-art processing factories, and then we securely packed, shipped and delivered for you. Our team is here to taking care and making sure that you always get the fastest and highest quality service.As a professional stone manufacture, we know quality is of the great importance, “Quality is the life of the factory, reputation is the foundation of business” which is our maxim. We have strict inspection program during each working procedure, block selection, processing, packing, marking, transportation…We promise: we will never deliver rejected goods to the clients! Currently, we have two plants which specialized in Basalt,Lava,granite products in China.Our products included the floor tile, slab, sink, swimming pool edge,window sill,cobblestone,crazy paver,walling cladding and so on. The finishing we can supply are Sawn,Honed,Flamed,Polished, Brush,Sandblasted, Bush-Hammered, Chiseled, Rock-Pitch Etc.

So come and see us. The beauty of natural stone can only be appreciated by seeing it first hand.And we are always updating our range, so a trip to our factory is worth it.

We can do much better because we are more professional and more committed!

Travertine and Sandstone Veneerstone in Curtain Wall Applications

Travertine is a trade name used for porous limestone and porous tuff. This stone type contains numerous holes, with their size and distribution varying based on the type of sandstone veneerstone and its origin.

Characteristics of Travertine & Sandstone Veneerstone

🔸 Low strength & loose texture

🔸 Easily accumulates water in holes

🔸 Poor freeze-thaw resistance & weather durability

🔸 High risk of breakage during transport & installation

Compared to granite, the performance of travertine and sandstone veneerstone is significantly lower, making them more prone to safety issues. Before selecting these materials for curtain wall panels, owners and designers must conduct a thorough assessment.

Basic Requirements for Using Travertine & Sandstone in Curtain Walls

Since these materials have weaker properties, they are generally not recommended for curtain walls. However, if architectural design requires their use, minimum performance standards must be met.

1. Bending Strength Test

Each batch of sandstone veneerstone and travertine intended for curtain wall use must undergo a bending strength test, ensuring the following requirements:

✅ For curtain walls ≤ 80m in height:

- Average strength ≥ 5N/mm²

- Minimum strength ≥ 4N/mm²

✅ For curtain walls > 80m in height:

- Average strength ≥ 6N/mm²

- Minimum strength ≥ 4.5N/mm²

✅ Force direction requirements:

- One-way force-bearing slate → Must meet above standards in its main force direction.

- Two-way force-bearing stone slab → Must meet above standards in both force directions.

Conclusion

Travertine and sandstone veneerstone are weaker than granite and prone to structural issues. When used for curtain walls, strict testing and engineering precautions must be followed to ensure safety and durability. Careful material selection and compliance with bending strength standards are essential for preventing long-term risks.

Share