1

/

of

9

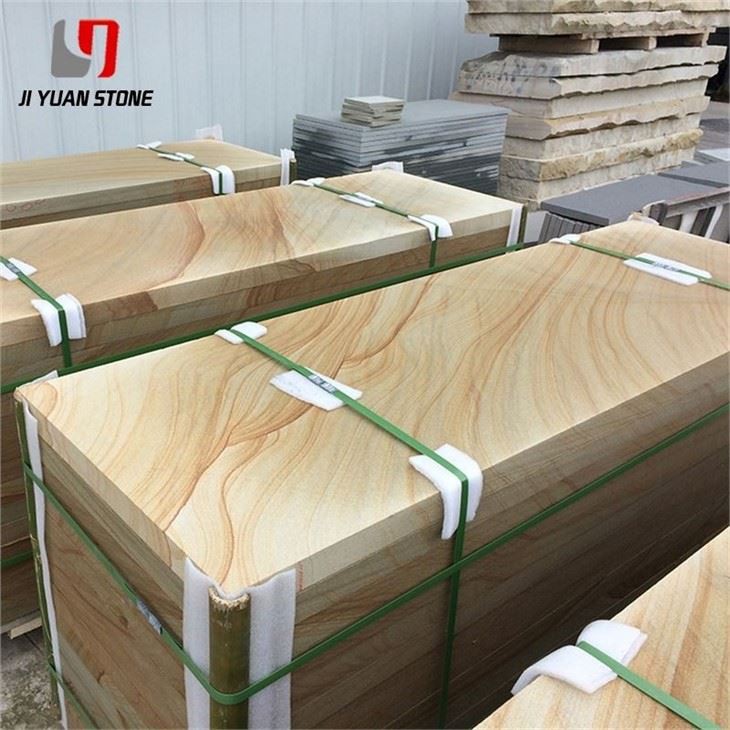

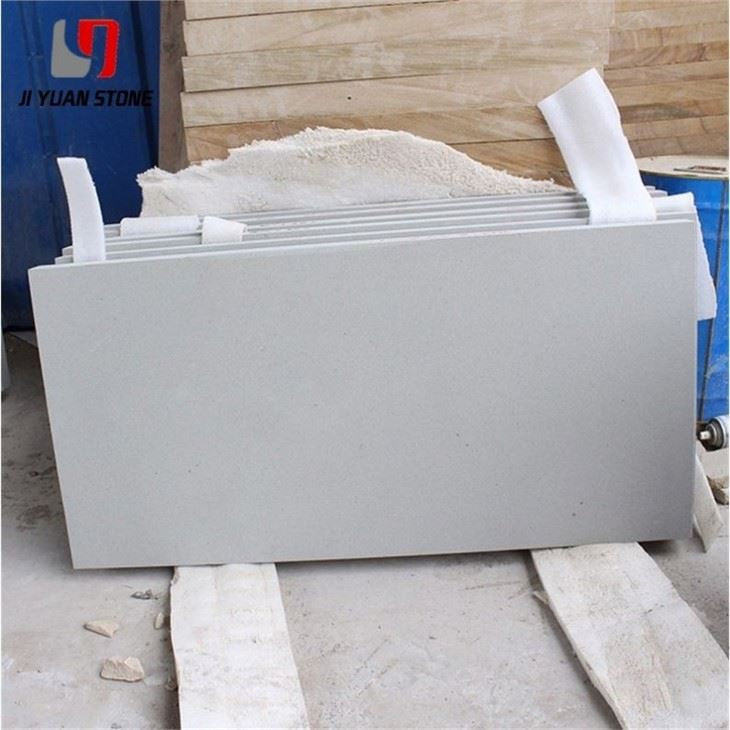

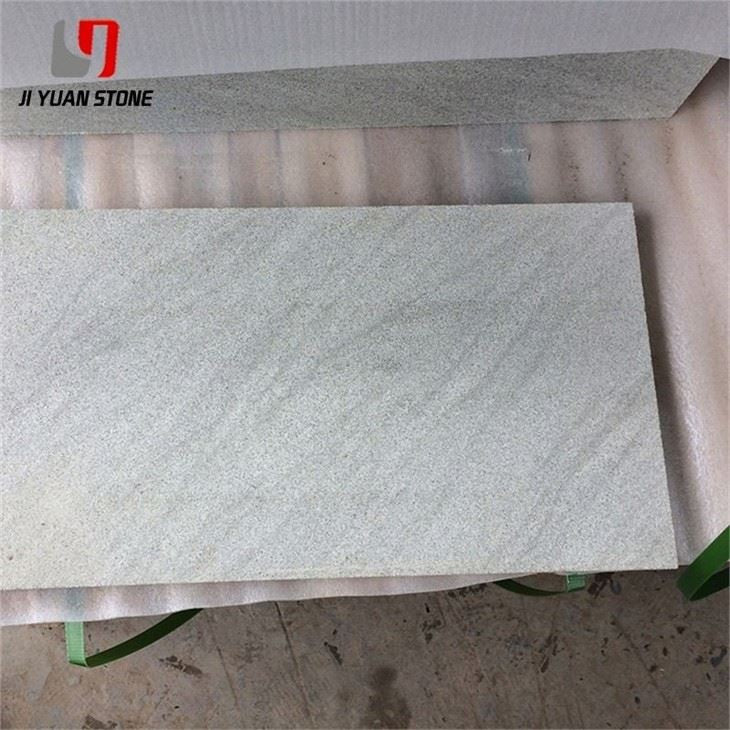

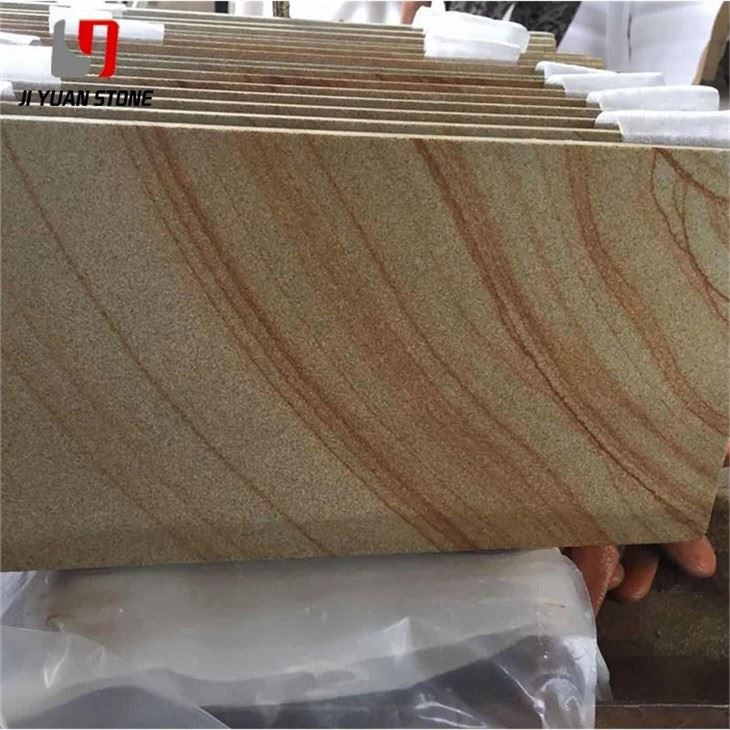

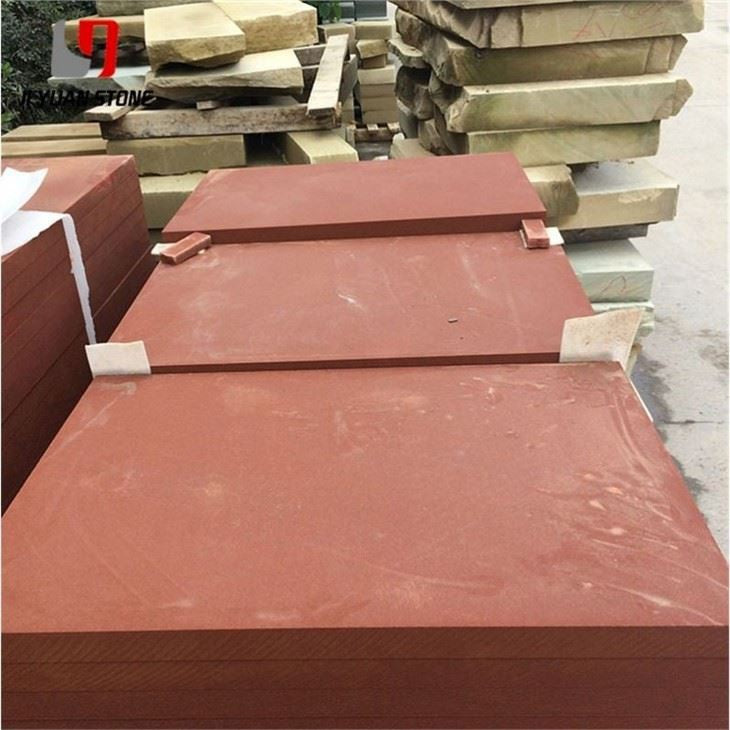

Sandstone Stone Steps

Sandstone Stone Steps

These Sandstone Stone Steps are the perfect addition to any outdoor space. Crafted from high-quality sandstone, these steps provide durability and a natural look to your landscape. With their smooth surface and sturdy structure, they offer easy access and enhance the overall aesthetic of your home.

| Feature | Details |

|---|---|

| Materia | Natural Sandstone |

| Surface Finished | Honed,Flamed,Bush-hammered,Brushed,Nature,Mushroom,Sawn etc |

| Finished Products | Floor tiles, Wall cladding, Countertops, Windowsills, Special-shaped tiles, Small slabs, Swimming pool, steps, wall panel, flooring, veneers, slabs, coping tiles, etc |

| Color | Yellow,black,white,red,purple wood,green,grey,rainbow etc |

| Applications | Slabs, tiles including walling tiles, and flooring tiles, kitchen countertops, vanity tops, work tops, window sills, skirting, steps & riser stairs. |

| Available Sizes |

|

| Available Thickness | 3/8”(10mm), 12mm, 15mm, 3/4”(20mm), 30mm or other thickness as customization. |

Our advantages:

a) Owner of professional factories and quarries.

b) Experienced and have sophisticated craftsmanship.

c) With strict control of every process and quality-inspected.

d) Have big stock, prompt delivery and good fame in stone industry.

Suggestions During Construction

1. Strength Characteristics of Red Sandstone Stone Steps:

- The uniaxial compressive strength in dry state: 30-60 MPa

- The uniaxial compressive strength in natural state: 15-30 MPa

- The uniaxial compressive strength in saturated state: 0-20 MPa

- Mineral Composition: Mainly quartz, feldspar, rock chips, and muddy components

2. Roadbed Filling Recommendations:

- Use a YZ20 or larger roller (maximum exciting force ≥ 350KN).

- Control loose pavement thickness at 35 cm.

- Ensure maximum particle size before paving is within 23 cm.

3. Construction Monitoring:

- Strictly monitor loose pavement thickness and maximum particle size.

- Due to red sandstone’s sensitivity to compaction detection accuracy, controlling the number of compaction passes is crucial for project quality.

4. Improving Roadbed Quality:

- To enhance single-point qualification rate, use large tonnage compaction machines for stamping reinforcement.

- If using a CYZ25 impact roller, ensure:

-

-

- Average settlement within 7 cm.

- Single-point pass rate of over 90% for qualified subgrade quality.

-

Share