Sandstone Slab Stairs

Sandstone Slab Stairs

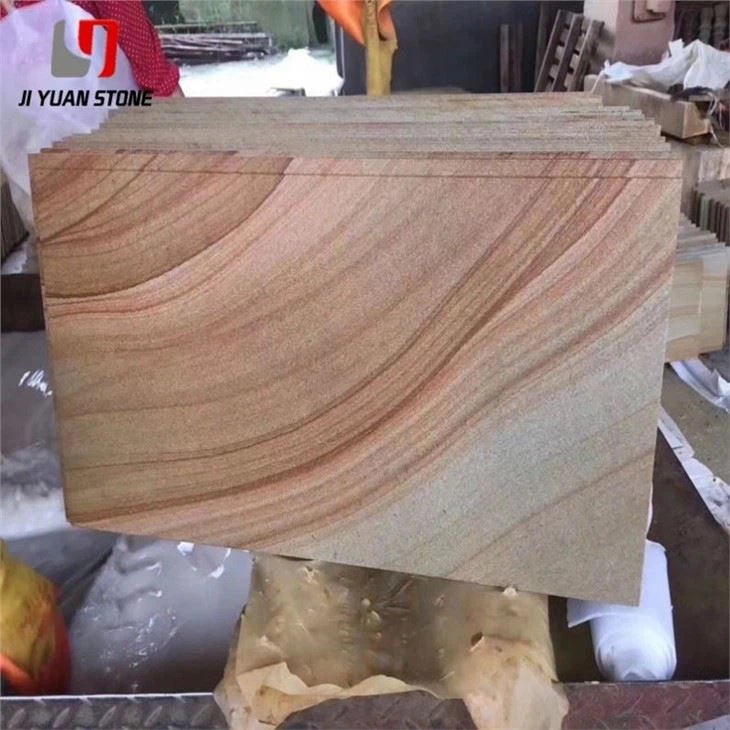

Sandstone Slab Stairs: On-Site Analysis, Installation Solutions & Precision Positioning

Crafted from high-quality sandstone material, our Sandstone Slab Stairs are a durable and stylish addition to any home or outdoor space. With their sturdy construction and natural texture, these stairs provide a safe and attractive way to elevate your space. Perfect for adding an elegant touch to your landscaping or creating a functional pathway.

| Feature | Details |

|---|---|

| Material | Natural Sandstone |

| Surface Finished | Honed,Flamed,Bush-hammered,Brushed,Nature,Mushroom,Sawn etc |

| Finished Products | Floor tiles, Wall cladding, Countertops, Windowsills, Special-shaped tiles, Small slabs, Swimming pool, steps, wall panel, flooring, veneers, slabs, coping tiles, etc |

| Color | Yellow,black,white,red,purple wood,green,grey,rainbow etc |

| Finished | Honed, Split, Sandblasted, Sawn, Antiqued, Pineapple, etc. |

| Dimension |

|

| Usage | Interior & Exterior Decoration |

| Quality Control |

Thickness Tolerance:+/-0.5mm,+/-1mm; All Products Checked by Experienced QC |

| MOQ | Welcome Small Trail Orders |

| Size | Customized Pls contact us for the newest catalog of sandstone,marble,granite,quartz,mosaic,limestone,travertine etc |

| Sample | Contact Us For Free Samples |

| Package | Standard Exporting Seaworthy Package ( Inner: Plastic Film and Foam; Outer: strong seaworthy wood Crates or Pallets.)Payment |

| Payment | T/T, L/C, Escrow, Western Union |

| Delivery | Within 2 Weeks After Deposit |

Our sandstone slab stairs combine natural elegance with structural precision, tailored for modern architectural projects requiring durability and aesthetic appeal. Understanding the on-site conditions and applying accurate installation methods are critical for flawless staircase construction.

Analysis of On-Site Stairs and Solutions

1 . Spiral Staircase Analysis

The spiral staircase features a welded steel structure that guarantees standardized sizing and a perfect circular shape. It matches the height of a straight staircase, with each step height equally divided based on the total height from the first floor to the second floor. This ensures uniform step dimensions and a comfortable climb.

2 . Sandstone Slab Stairs

The sandstone slab stairs present installation challenges due to steel plates raised on both sides, complicating step panel fixation. To overcome this, use a vertical line to accurately determine the step corner points during installation.

Three cement foundation walls surrounding the stairs serve as reliable cross-reference lines for precise placement.

Positioning Reference Line

1 . Measurement and Alignment

- Use infrared rays to verify that the three foundation walls form a perfect 90° angle.

- Measure the X-axis to confirm it is parallel to wall B and ensure the Y-axis is perpendicular and parallel to walls A and B.

2 . Reference Line Application

- Establish a cross-coordinate reference line on-site, marking it clearly with an ink fountain line on the wall or ground.

- All subsequent installation steps must adhere strictly to this initial reference line for accuracy.

- It is essential to keep the reference line visible throughout construction—avoid covering it with paint or putty powder.

- Maintain communication with the on-site project manager to ensure the reference line remains intact and is used as a guide throughout the project.

Our sandstone slab stairs deliver unmatched quality and precision, backed by thorough on-site analysis and strategic installation guidance. Trust our expert solutions for staircases that blend structural soundness with elegant stone craftsmanship.

Share