1

/

of

11

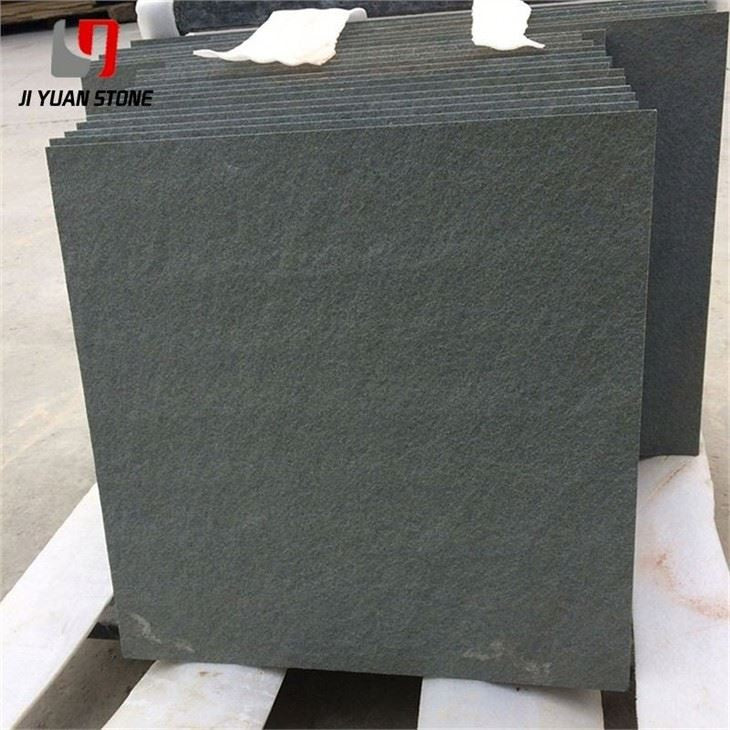

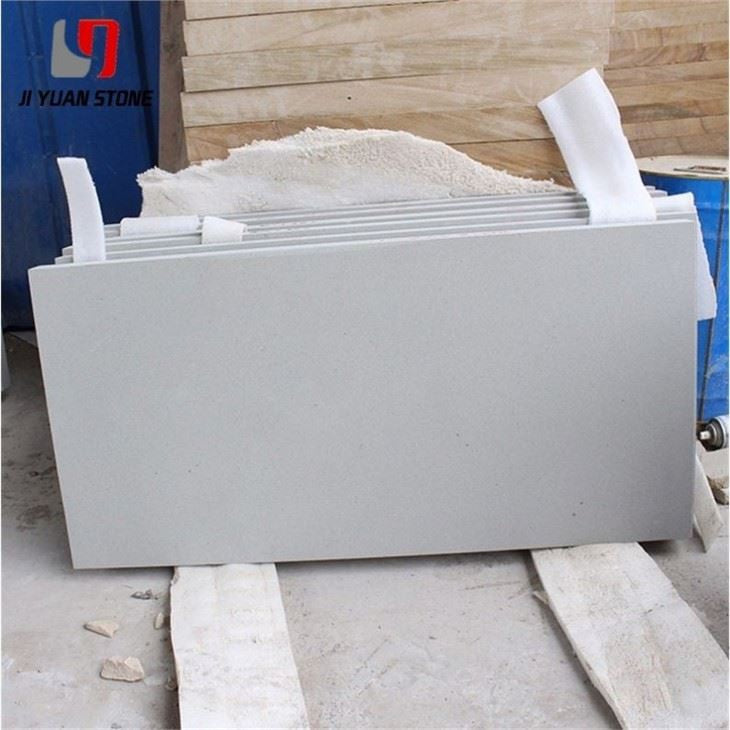

Sandstone Paving Tiles

Sandstone Paving Tiles

Enhance your outdoor space with our durable and versatile Sandstone Paving Tiles. Made from high-quality sandstone, these tiles are perfect for creating a stylish and long-lasting patio or walkway. With a variety of design options, you can easily transform your space into an inviting and functional area for years to come.

| Feature | Details |

|---|---|

| Materia | Natural Sandstone |

| Surface Finished | Honed,Flamed,Bush-hammered,Brushed,Nature,Mushroom,Sawn etc |

| Finished Products | Floor tiles, Wall cladding, Countertops, Windowsills, Special-shaped tiles, Small slabs, Swimming pool, steps, wall panel, flooring, veneers, slabs, coping tiles, etc |

| Color | Yellow,black,white,red,purple wood,green,grey,rainbow etc |

Sandstone Paving Tiles: Construction, Cleaning & Sealing Guide

Construction Process

1. Leveling the Surface

- Use a hammer handle or soft wood (e.g., Chinese fir) to gently tap the sandstone surface for an even finish.

- This method helps achieve a smooth horizontal alignment and straight lines.

2. Cleaning & Drying

- Wipe the surface with a sponge to absorb excess water from the joints and tiles.

- Avoid walking on the freshly installed tiles for 6-8 hours.

3. Edge Sealing & Joint Filling

- Use dry, clean concrete or SIKAFLEX 11 FC to fix the edges.

- After 24 hours, fill joints with a mixture of clean sand, cement, and lime (3:1:1 ratio).

- Wet the joints, apply tan-colored grout, and smooth them using a bricklayer’s trowel.

- Rinse off any excess material with clean water.

4. Metal Fastening & Final Touches

- Use copper or 316 stainless steel fasteners for iron nails.

- If epoxy is required, ensure it’s used only for objects with minimal plastic expansion.

- Follow steps a-k in order to complete the installation.

5. Final Edge Grinding

- If tile edges appear uneven, skilled workers will smooth them using silicon carbide (a grindstone commonly used for concrete).

Cleaning Guidelines (After 3-5 Days)

- Step 1: Rinse the surface thoroughly with clean water.

- Step 2: Apply a manufacturer-recommended detergent, mop the surface, and clean it thoroughly.

- Step 3: For heavy dirt or dust, use a pressure washer (2000 psi max) for deep cleaning.

Sealing Process

- If sealing is required, allow the surface to dry for at least 1-2 days in sunny weather before application.

Share