Sandstone Pavers Steps

Sandstone Pavers Steps

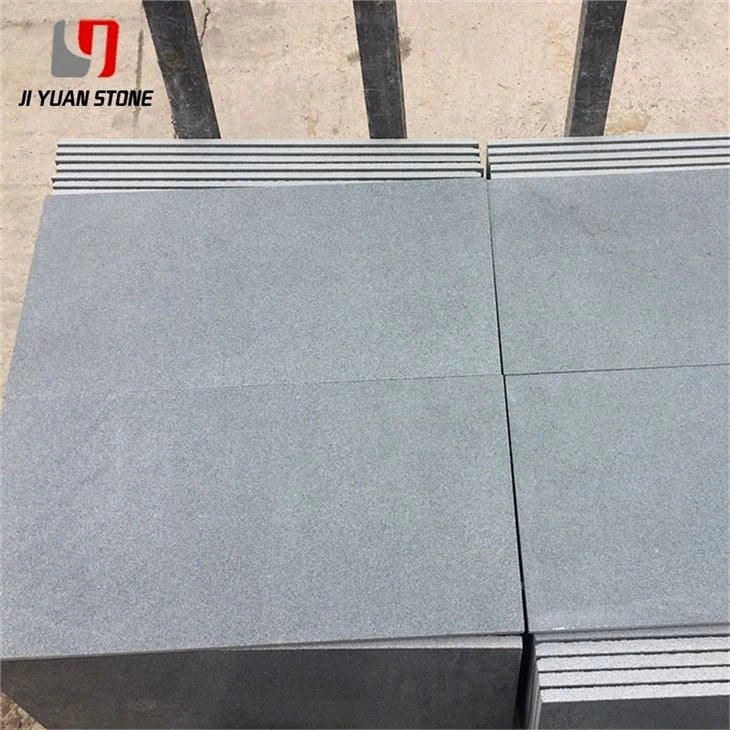

Custom Sandstone Pavers Steps – Precision Engineered for Landscape Excellence

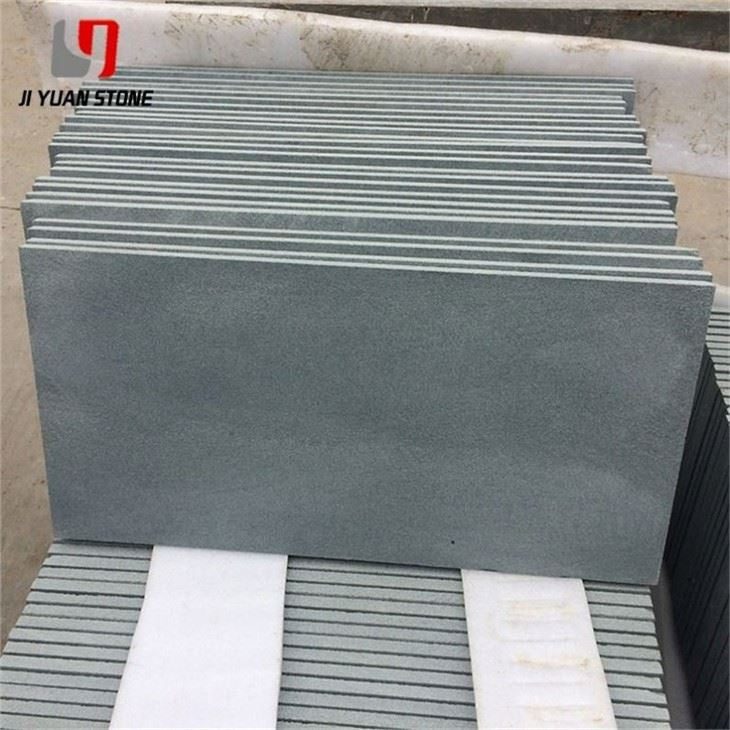

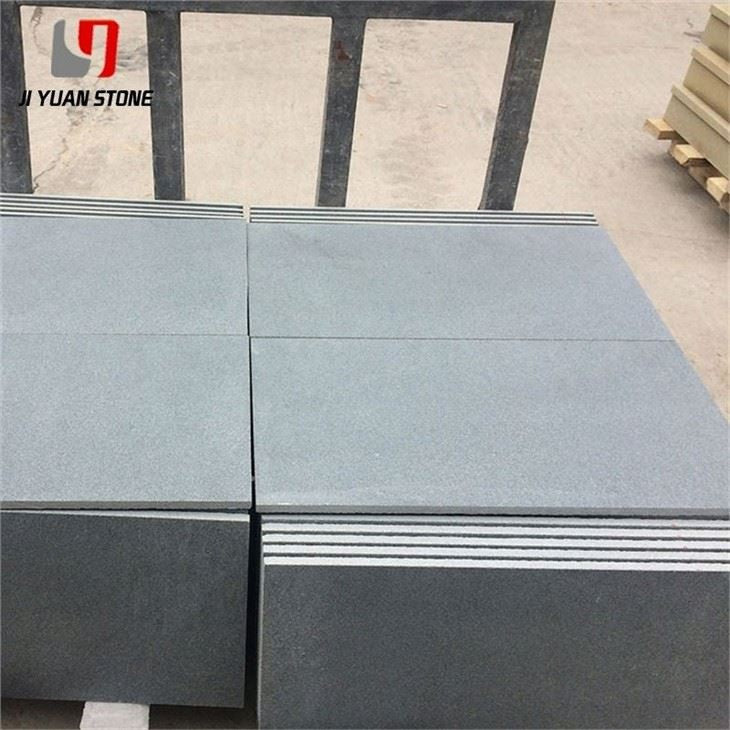

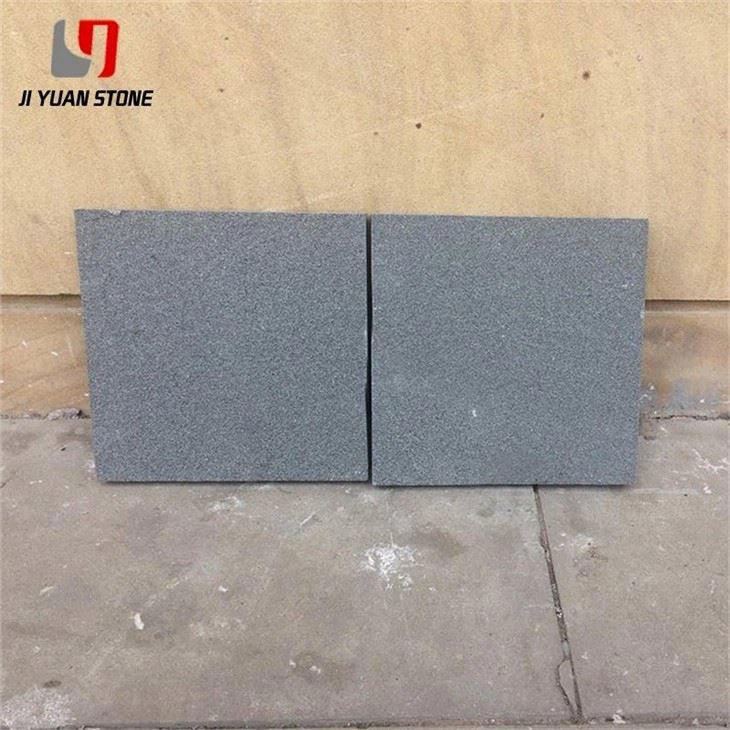

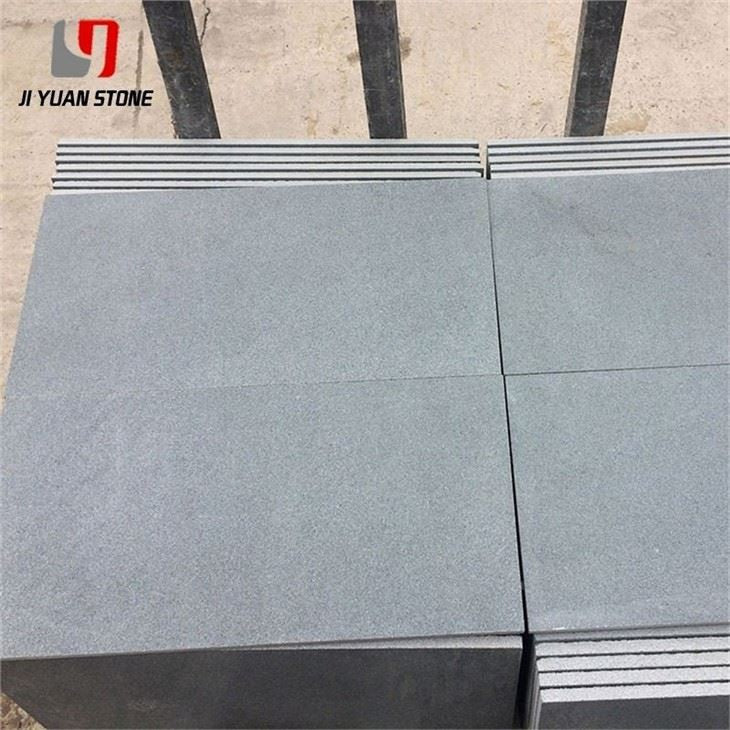

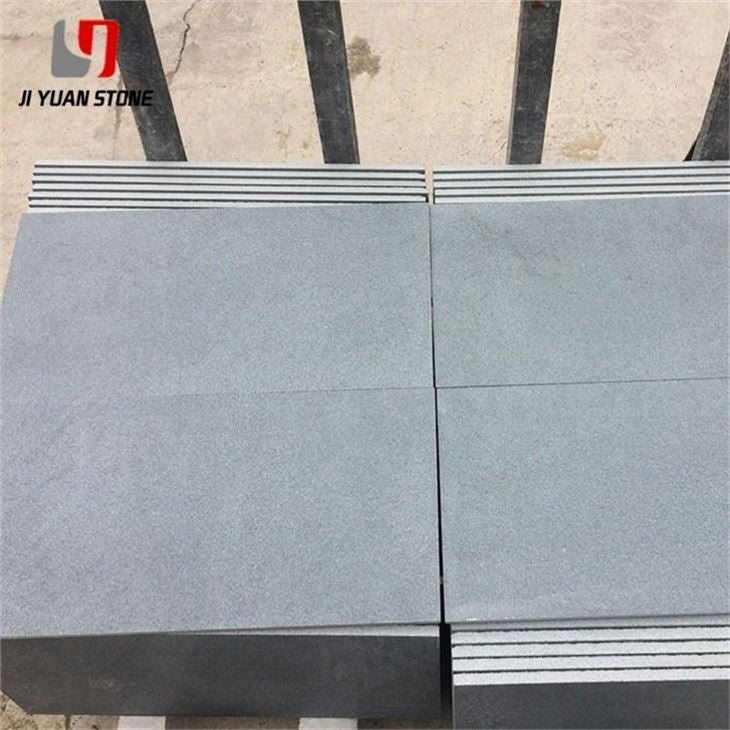

Crafted from durable sandstone, these pavers steps add functionality and style to any outdoor space. With its natural texture and slip-resistant surface, they provide stability and safety, making them perfect for creating a beautiful and practical pathway or step. Enhance your landscape with these versatile and timeless pavers.

| Feature | Details |

|---|---|

| Material | Natural Sandstone |

| Surface Finished | Honed,Flamed,Bush-hammered,Brushed,Nature,Mushroom,Sawn etc |

| Finished Products | Floor tiles, Wall cladding, Countertops, Windowsills, Special-shaped tiles, Small slabs, Swimming pool, steps, wall panel, flooring, veneers, slabs, coping tiles, etc |

| Color | Yellow,black,white,red,purple wood,green,grey,rainbow etc |

| Finished | Honed, Split, Sandblasted, Sawn, Antiqued, Pineapple, etc. |

| Dimension |

|

| Usage | Interior & Exterior Decoration |

| Quality Control |

Thickness Tolerance:+/-0.5mm,+/-1mm; All Products Checked by Experienced QC |

| MOQ | Welcome Small Trail Orders |

| Size | Customized Pls contact us for the newest catalog of sandstone,marble,granite,quartz,mosaic,limestone,travertine etc |

| Sample | Contact Us For Free Samples |

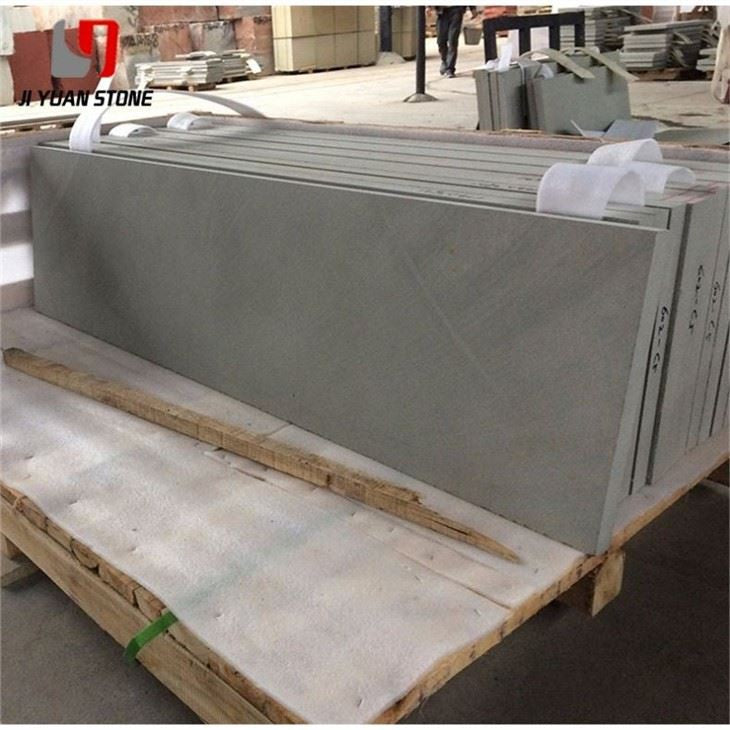

| Package | Standard Exporting Seaworthy Package ( Inner: Plastic Film and Foam; Outer: strong seaworthy wood Crates or Pallets.)Payment |

| Payment | T/T, L/C, Escrow, Western Union |

| Delivery | Within 2 Weeks After Deposit |

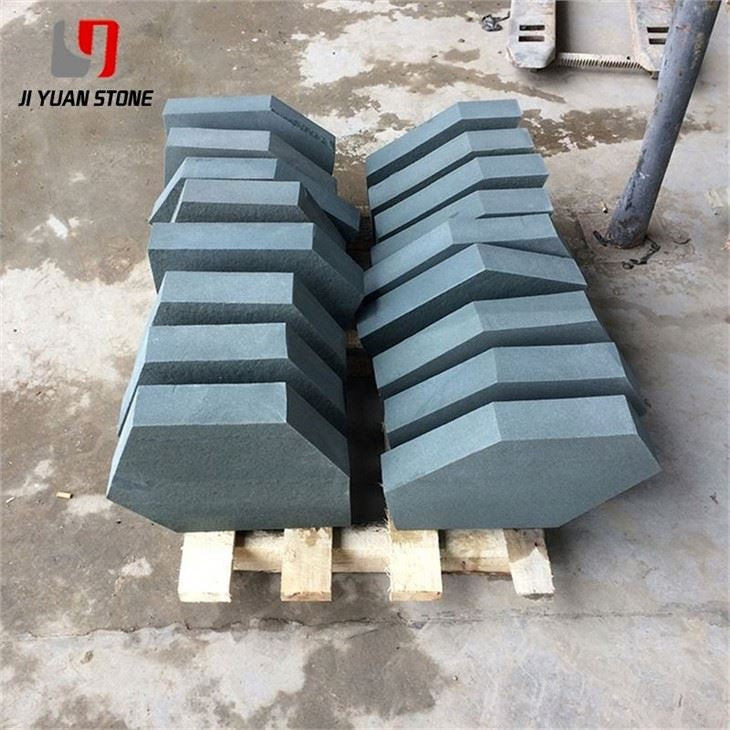

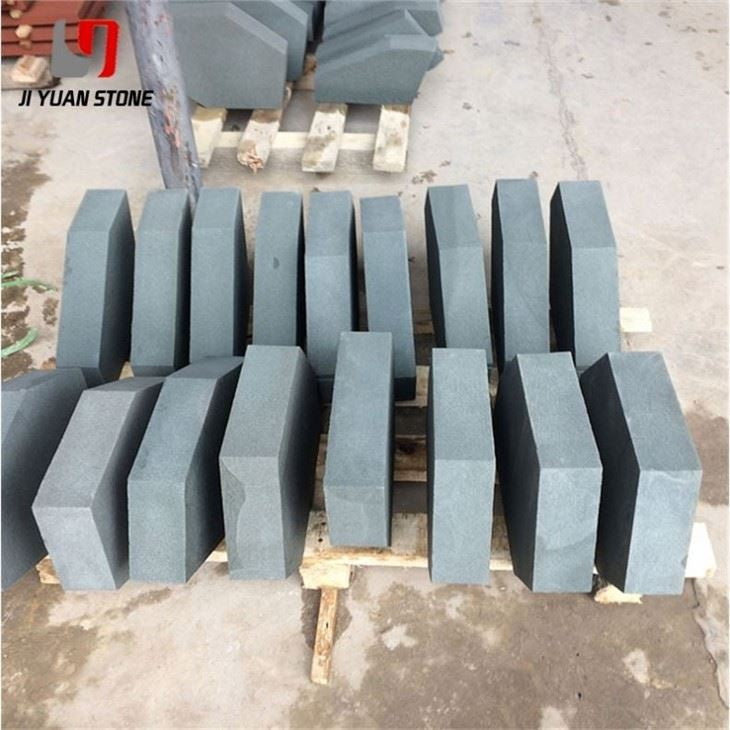

Elevate your architectural and landscape projects with our custom sandstone pavers steps—a premium solution combining durability, aesthetic appeal, and expert craftsmanship. These natural stone steps are designed for outdoor and garden environments where both form and function are essential.

Each piece is meticulously cut, reviewed, and optimized through a detailed design process that ensures accurate installation, minimal material waste, and stunning visual results.

How to Manage Sandstone Pavers Steps Orders Efficiently

Our process for delivering top-tier sandstone pavers steps follows a structured project management approach to ensure flawless results from design to delivery.

1. Drawing Review

A comprehensive joint review of the construction drawings is the first step toward ensuring smooth execution. This includes:

- Verifying the clarity and placement of sandstone pavers steps in the plans

- Evaluating the suitability of stone thickness for load and usage requirements

- Ensuring coordination with landscape design features

- Assessing the feasibility of construction based on current site conditions

- Confirming the market availability of specified stone materials

Following the review, we prepare a signed review report endorsed by Party A, the design team, and project supervisors to serve as a settlement reference for the project’s financial and construction planning.

2. Drawing Deepening and Optimization

Once the initial drawing review is approved, we deepen and optimize the layout based on site-specific and structural needs. This phase includes:

- Creating a “one diagram and one table” layout for step-by-step clarity

- Using CAD for detailed mapping of pavers to ensure modular alignment and dimension accuracy

- Optimizing seams in single steps, especially around trees, pools, and water features

- Adjusting small steps to align with surrounding flooring for seamless central axis integration

- Enhancing corner transitions with corner boards or extended versions

- Verifying the need for custom cuts and special processing for curved or irregular shapes

This precision ensures that all sandstone pavers steps contribute to a unified and elegant outdoor layout.

Key Features of Our Sandstone Pavers Steps

- ✅ Natural sandstone with exceptional slip resistance

- ✅ Custom cut-to-size options to fit any design specification

- ✅ Weather-resistant surface, perfect for outdoor durability

- ✅ Professional-grade design review for optimized installation

- ✅ CAD-optimized layouts for accuracy and minimal waste

- ✅ Ideal for pathways, stairs, and landscaped elevations

Applications

Our sandstone pavers steps are ideal for:

- Residential and villa landscaping

- Commercial courtyards and pathways

- Public parks and urban renewal projects

- Poolside and water feature surroundings

- Monumental staircases and garden steps

Conclusion

With a foundation in expert planning and design, our sandstone pavers steps offer the perfect blend of technical precision and natural beauty. From initial drawing review to CAD-driven optimization, we deliver not just stone—but a solution tailored to your project’s success.

Choose Purchasestones for sandstone steps that are engineered for performance, crafted for elegance, and managed for cost efficiency.

Share